Pneumatic continuous feeding device

A technology of feeding device and cylinder, which is applied in the field of pneumatic continuous feeding device, can solve the problems of no-load feeding system, prone to jamming and jamming, etc., and achieve the effect of smooth feeding and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

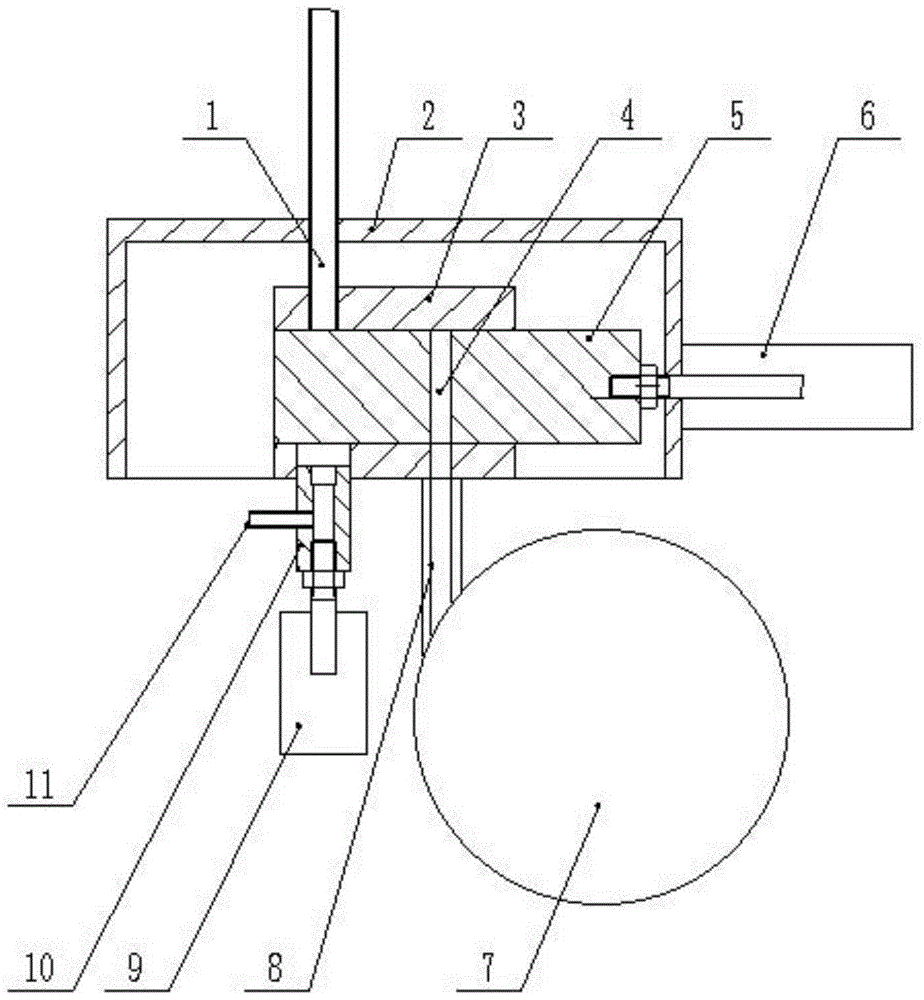

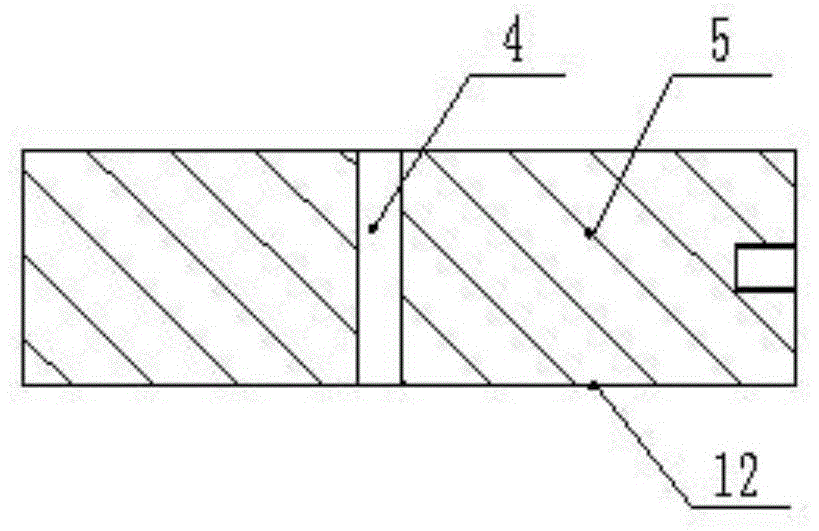

[0019] The pneumatic continuous feeding device, as shown in the accompanying drawings, includes a vibrating plate 7, a first pipe 10 connected to a high-pressure air source, and a slider 5 and a second pipe 1. The first pipe 10 can move along its axis, and the first pipe 10 can move along its axis. The axis of the first tube 10 coincides with the axis of the second tube 1, the slider 5 is provided with a through hole 4, the slider 5 can move so that the axis of the through hole 4 coincides with the axis of the first tube 10, and the slider 5 is close to the first tube Both sides 10 and 12 of the second tube 1 are plane. The side 12 of the slide block 5 acts as a material separator, isolating the rest of the blanks in the vibrating disk feedway 8 to ensure that the materials are taken one by one.

[0020] A hose 11 is radially connected to the first pipe 10, and the hose 11 is connected to a high-pressure air source. The first pipe 10 is provided with a first cylinder 9 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com