Trackless gantry crane

A gantry crane and crane technology, which is applied to cranes, trolley cranes, transportation and packaging, etc., can solve problems such as large tunnel space, and achieve the effects of shortening construction period, convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

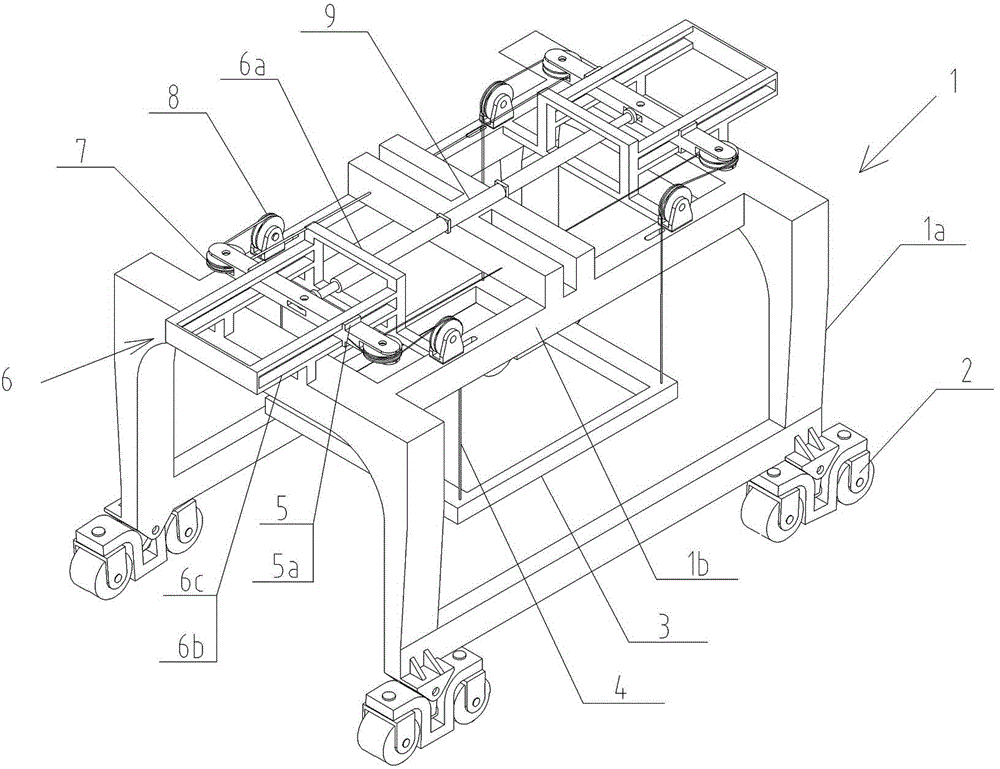

[0015] Such as figure 1 As shown, a trackless gantry crane provided by the present invention includes a crane frame 1 composed of a main girder 1b and a gantry 1a, the bottom of the gantry 1a is provided with a walking wheel 2 traveling along the shield segment, and the crane frame A sliding arm frame 6 is respectively arranged at symmetrical positions on both sides of the top. The sliding arm frame 6 is composed of a door-shaped vertical frame 6a and a door-shaped horizontal frame 6b. The corresponding sides of the door-shaped horizontal frame 6b are respectively provided with long holes 6c. A sliding arm 5 is connected to it for sliding cooperation. A pair of limit stops 5a are arranged on the upper and lower sides of the slide arm 5 respectively. 5 The two ends pass through the long holes 6c, and horizontal pulleys 7 are respectively provided, and vertical pulleys 8 are also provided on the main beam 1b on one side of each horizontal pulley, and a hydraulic cylinder 9 with ...

Embodiment 2

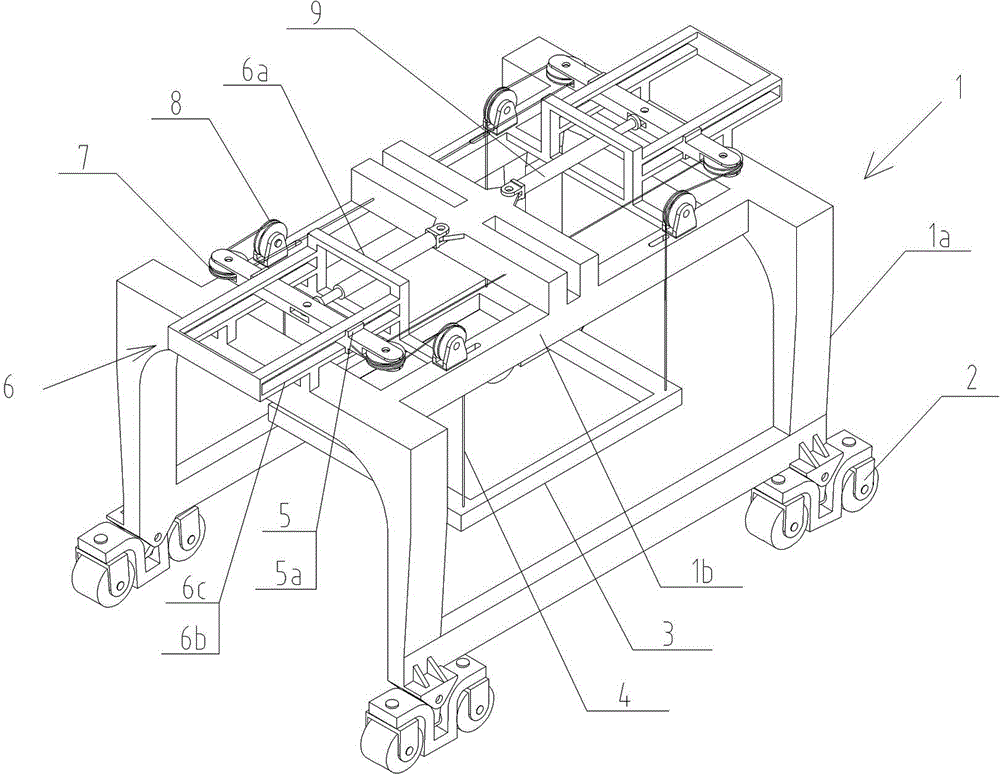

[0017] Such as figure 2 As shown, a trackless gantry crane provided by the present invention includes a crane frame 1 composed of a main girder 1b and a gantry 1a, the bottom of the gantry 1a is provided with a walking wheel 2 traveling along the shield segment, and the crane frame A sliding arm frame 6 is arranged at symmetrical positions on both sides of the top. The sliding arm frame 6 is composed of a door-shaped vertical frame 6a and a door-shaped horizontal frame 6b. The corresponding sides of the door-shaped horizontal frame 6b are respectively provided with long holes 6c. A sliding arm 5 is connected to it for sliding cooperation. A pair of limit stops 5a are arranged on the upper and lower sides of the slide arm 5 respectively. 5 The two ends pass through the long holes 6c, and are respectively provided with horizontal pulleys 7, and the main beam 1b on one side of each horizontal pulley is also provided with a vertical pulley 8, and the main beam is also provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com