U-shaped hollow Dacron draw-textured yarn and preparation method thereof

A technology for drawing textured yarn and hollowing, which is applied in hollow filament manufacturing, rayon manufacturing, filament/thread forming, etc., can solve the problems of small difference in POY raw fiber quality, production efficiency, and hollow fiber cross-section damage. To achieve the effect of soft and warm hand feeling, good pilling resistance and elasticity, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

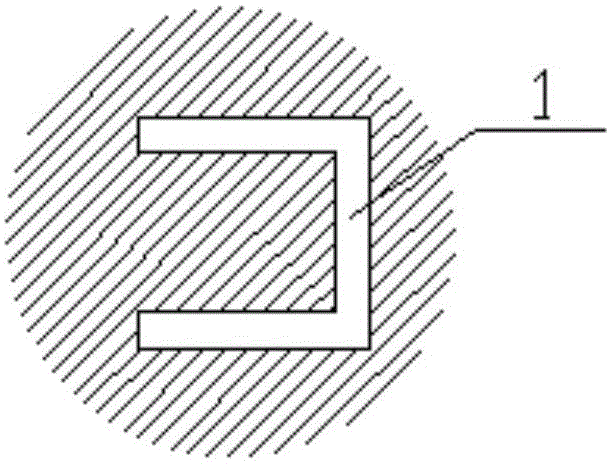

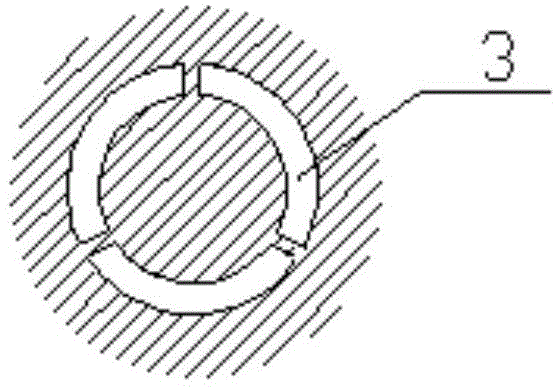

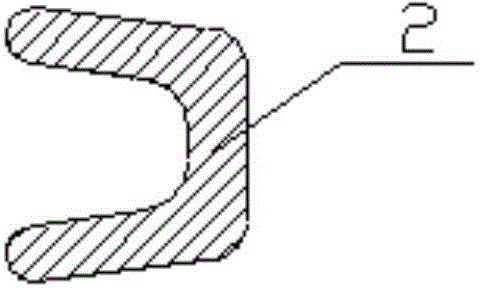

[0028] use as image 3 The spinneret shown produces 115dtex / 100f polyester pre-oriented yarn, and the semi-dull PET melt is extruded into bundles through a 100-hole spinneret, cooled by ring blowing, oiled on the bundles, wound and formed, and hollow and "U" are obtained. Shape polyester POY filaments, and then pass through the pre-net device → shredder → first roller → first hot box → cooling plate → false twister → tension meter → second roller → network nozzle → second hot box → third Roller → upper tanker → winding forming (DTY83dtex / 100f) to obtain hollow plus "U" shaped polyester stretch textured yarn. Among them, when the melt intrinsic viscosity is 0.67dl / g, the spinning temperature is 292°C, the spinning speed is 2600-2800m / min, the cooling air pressure is 25-35Pa, the side blowing temperature is 19°C, the length of the windless zone 40-70mm, oiling rate 0.7%, winding angle 5.6°-6.7°, contact pressure 140N-180N, DTY draft ratio 1.4-1.5, D / Y ratio 1.5-1.6. The fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Irregularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com