Landscape house roof bamboo hat block and production method thereof

A manufacturing method and a house technology, which are applied in the directions of roof, roof covering, roof covering with straw/wheat straw, etc., can solve the problems of short duration of decoration and ornamental effects, short use time of the top of the pavilion, and high use cost, and achieve Suitable for large-scale promotion, shortened installation time, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

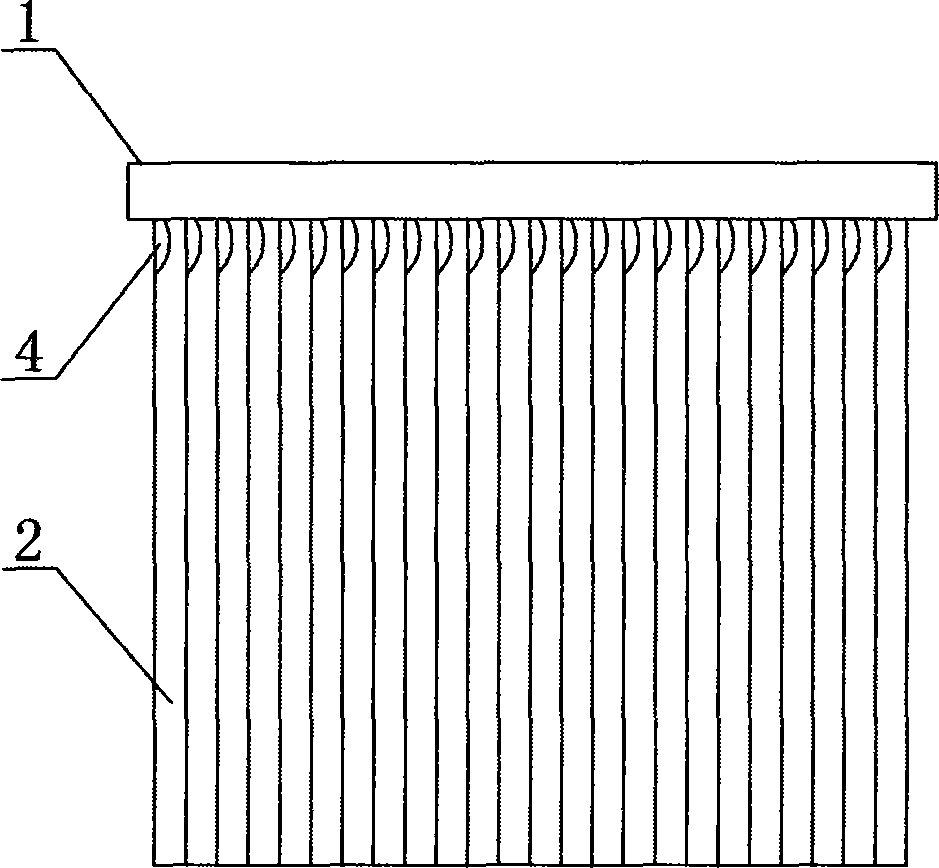

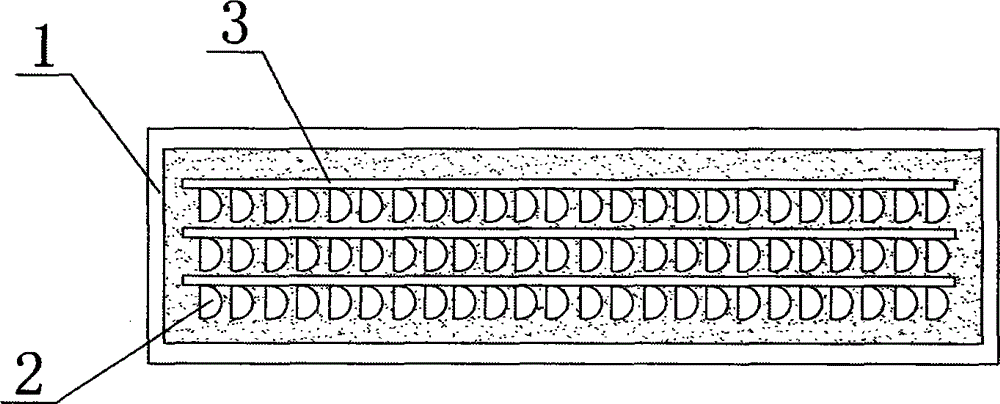

[0028] Embodiment 1: as figure 1 , figure 2 , Figure 5 As shown, a bamboo hat block for the roof of a landscape house includes a simulated plastic strip assembly and a fixed frame clamped at the root of one end of the simulated plastic strip assembly, wherein the simulated plastic strip assembly includes 3 layers stacked on the plastic strip layer, and each plastic strip layer includes It consists of a number of hollow tubular plastic strips and adhesive tape glued to one end of the plastic strips. The plastic strips on each plastic strip layer are arranged in parallel and placed closely. The two ends of each plastic strip are kept aligned. At one end side of the rear plastic strip, the adhesive tape is attached to each plastic strip of a plastic strip layer, so that each plastic strip layer forms a curtain-like structure; at one end of the simulated plastic strip component clamped by the fixed frame and the fixed frame between each layer of the plastic strip layer at this...

Embodiment 2

[0038] Embodiment 2: as figure 1 , image 3 , Figure 5As shown, a bamboo hat block for the roof of a landscape house includes a simulated plastic strip assembly and a fixed frame clamped at the root of one end of the simulated plastic strip assembly, wherein the simulated plastic strip assembly includes 4 layers stacked on the plastic strip layer, and each plastic strip layer includes It consists of a number of hollow tubular plastic strips and adhesive tape glued to one end of the plastic strips. The plastic strips on each plastic strip layer are arranged in parallel and placed closely. The two ends of each plastic strip are kept aligned. At one end side of the rear plastic strip, the adhesive tape is attached to each plastic strip of a plastic strip layer, so that each plastic strip layer forms a curtain-like structure; at one end of the simulated plastic strip component clamped by the fixed frame and the fixed frame between each layer of the plastic strip layer at this e...

Embodiment 3

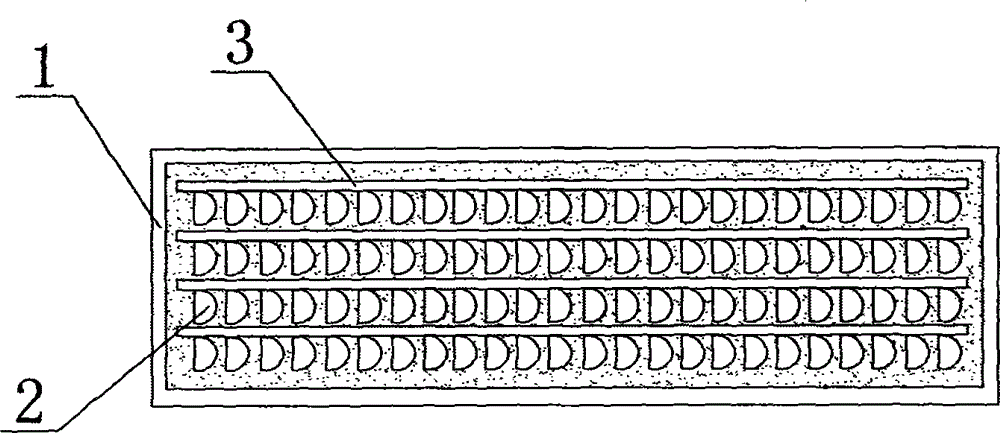

[0048] Embodiment 3: as figure 1 , Figure 4 , Figure 5 As shown, a bamboo hat block for the roof of a landscape house includes a simulated plastic strip assembly and a fixed frame clamped at the root of one end of the simulated plastic strip assembly, wherein the simulated plastic strip assembly includes 5 layers stacked on the plastic strip layer, and each plastic strip layer includes It consists of a number of hollow tubular plastic strips and adhesive tape glued to one end of the plastic strips. The plastic strips on each plastic strip layer are arranged in parallel and placed closely. The two ends of each plastic strip are kept aligned. At one end side of the rear plastic strip, the adhesive tape is attached to each plastic strip of a plastic strip layer, so that each plastic strip layer forms a curtain-like structure; at one end of the simulated plastic strip component clamped by the fixed frame and the fixed frame between each layer of the plastic strip layer at this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com