Patents

Literature

30results about "Roof covering using straw/thatch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

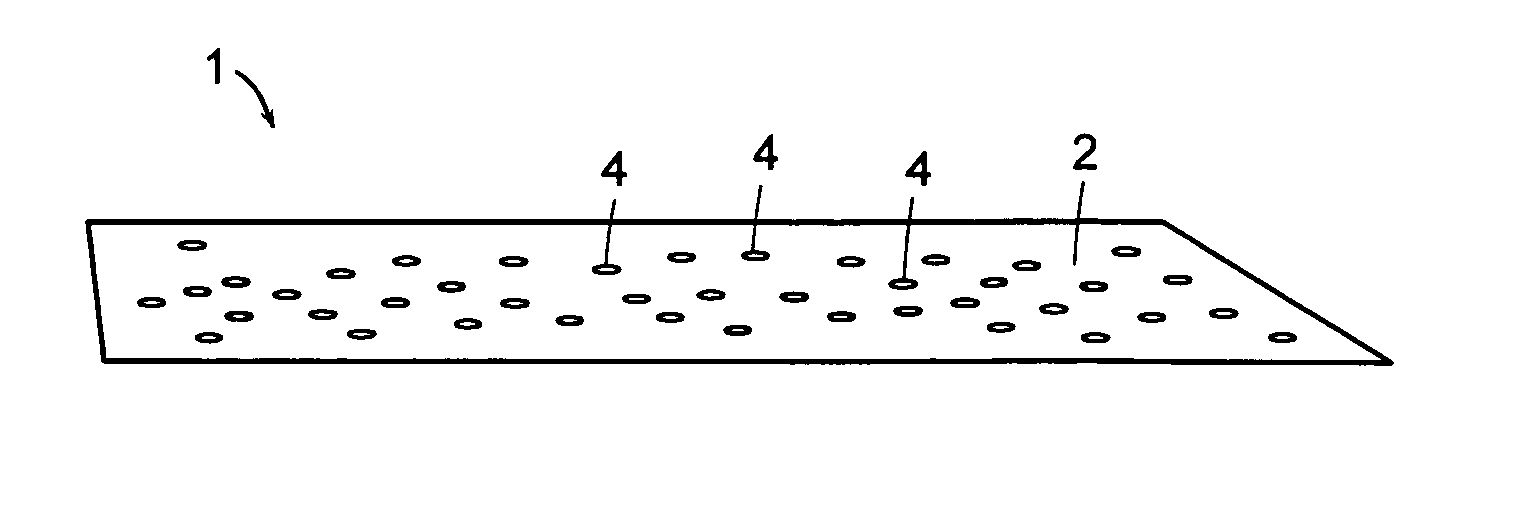

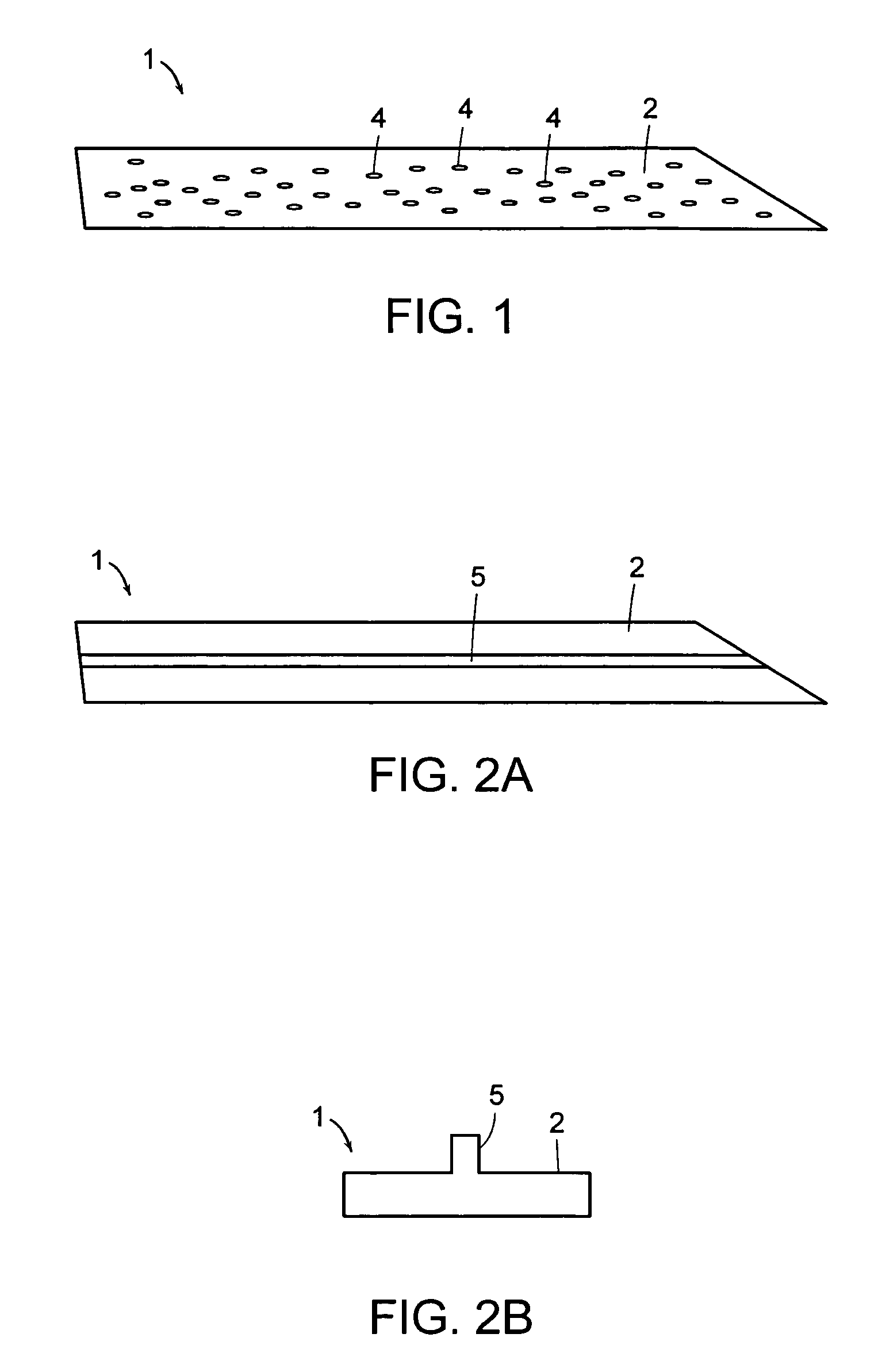

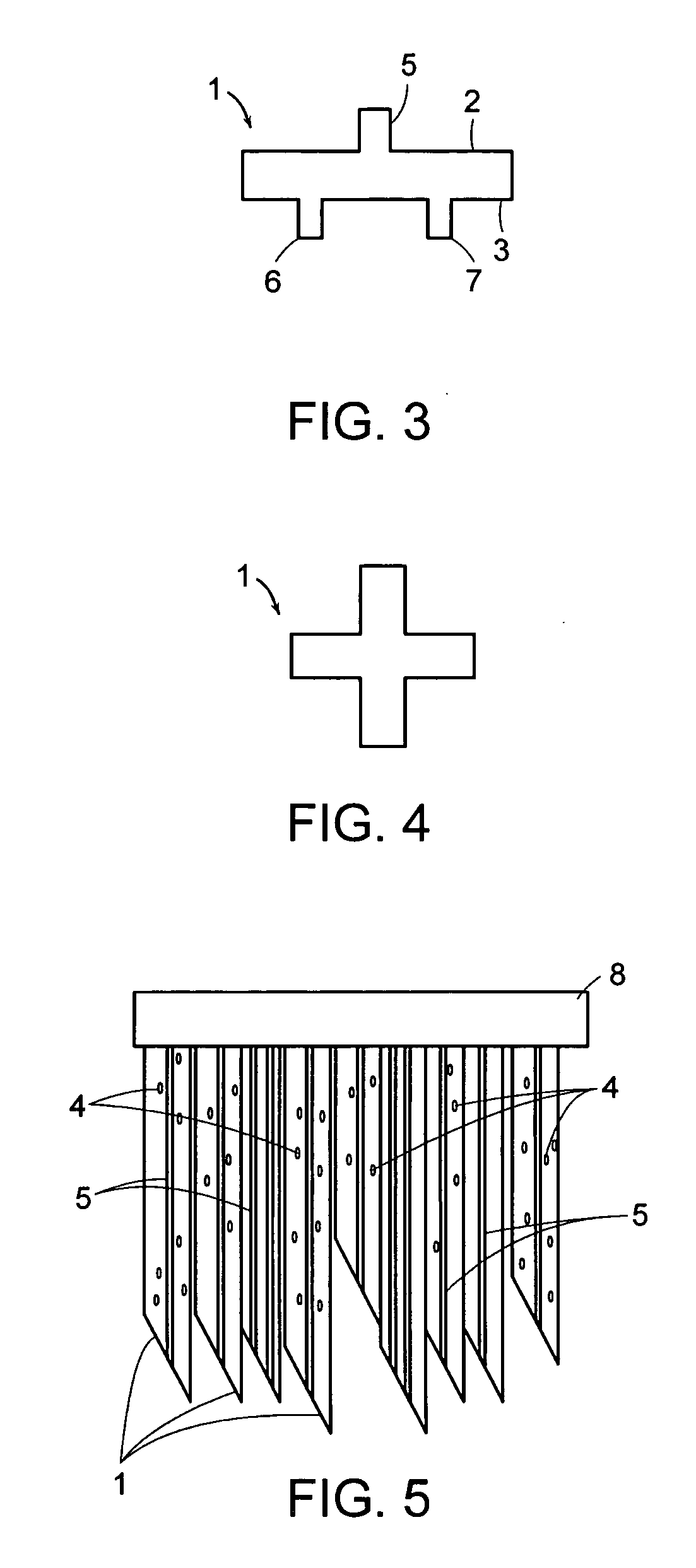

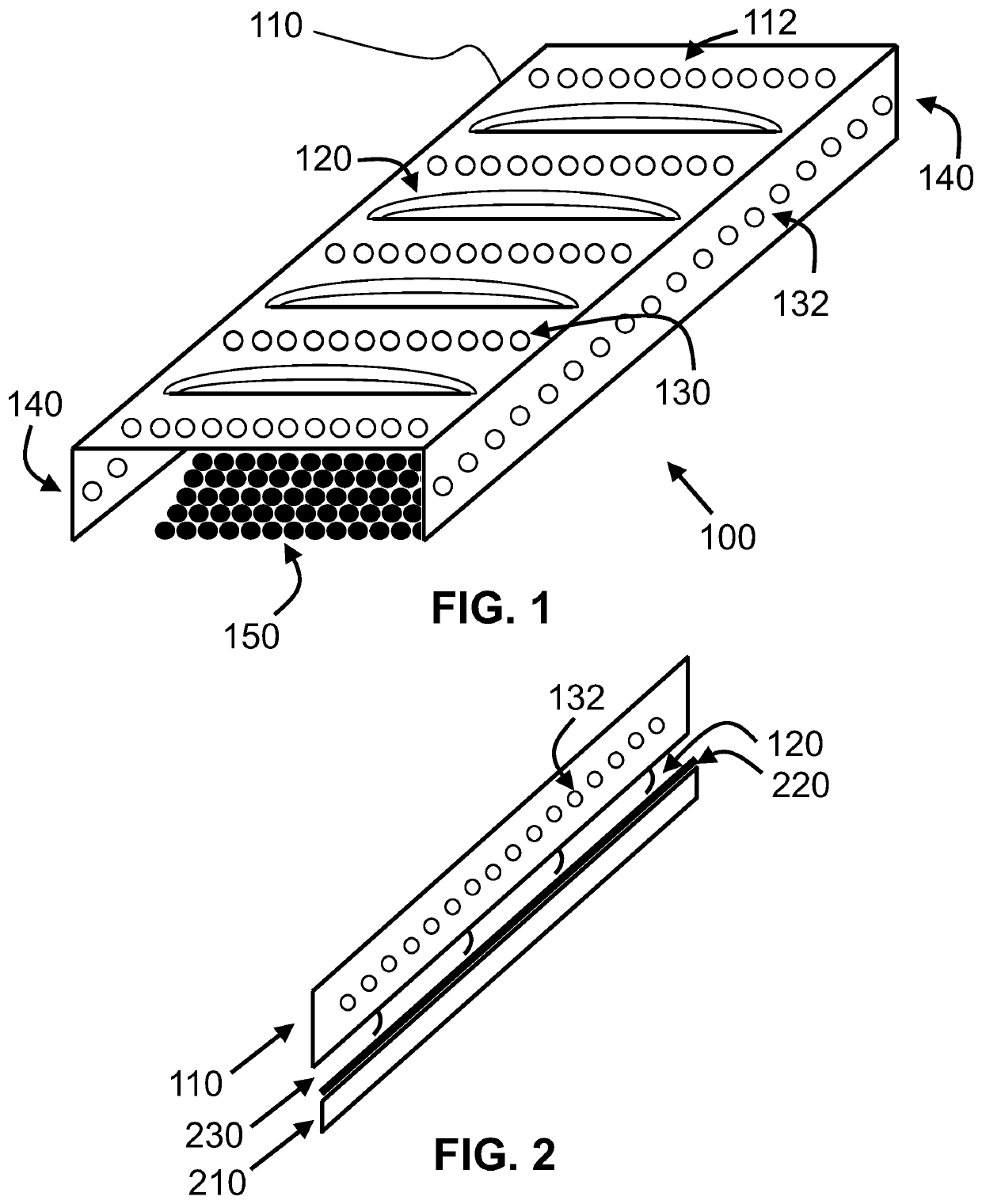

Synthetic textured thatch elements for building construction and methods of making the same

InactiveUS20050285293A1Efficiently and economically producedLayered productsRoof covering using straw/thatchArchitectural engineeringPolymer

The present invention provides a synthetic thatch element for building construction including an elongate polymer strip with one or more texture elements on at least one surface to provide a natural appearance. Thatch elements according to the invention can be incorporated into thatch element constructions for use in building construction. The present invention also provides methods for producing textured thatch elements.

Owner:BROWN JAMES MICHAEL +2

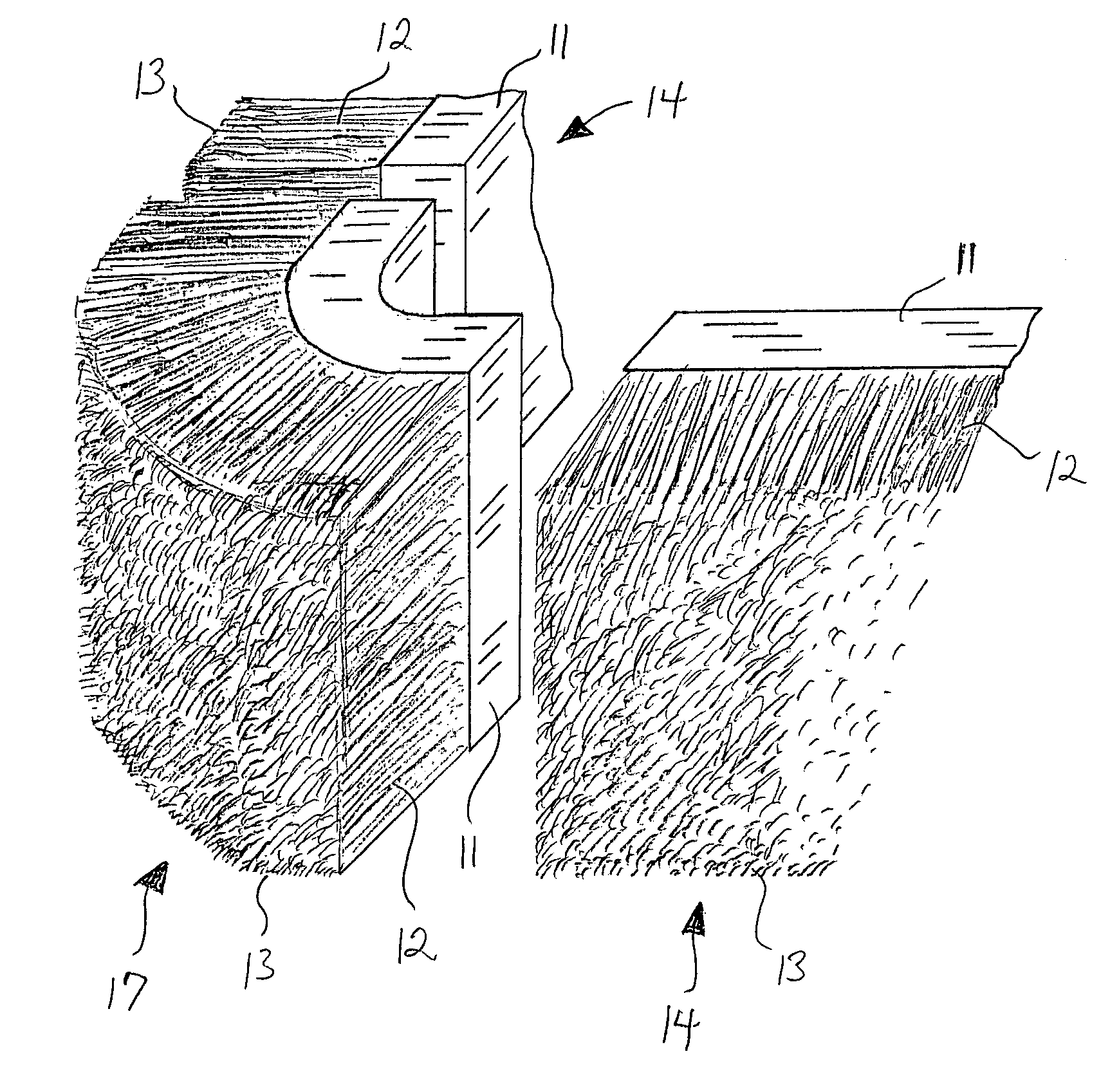

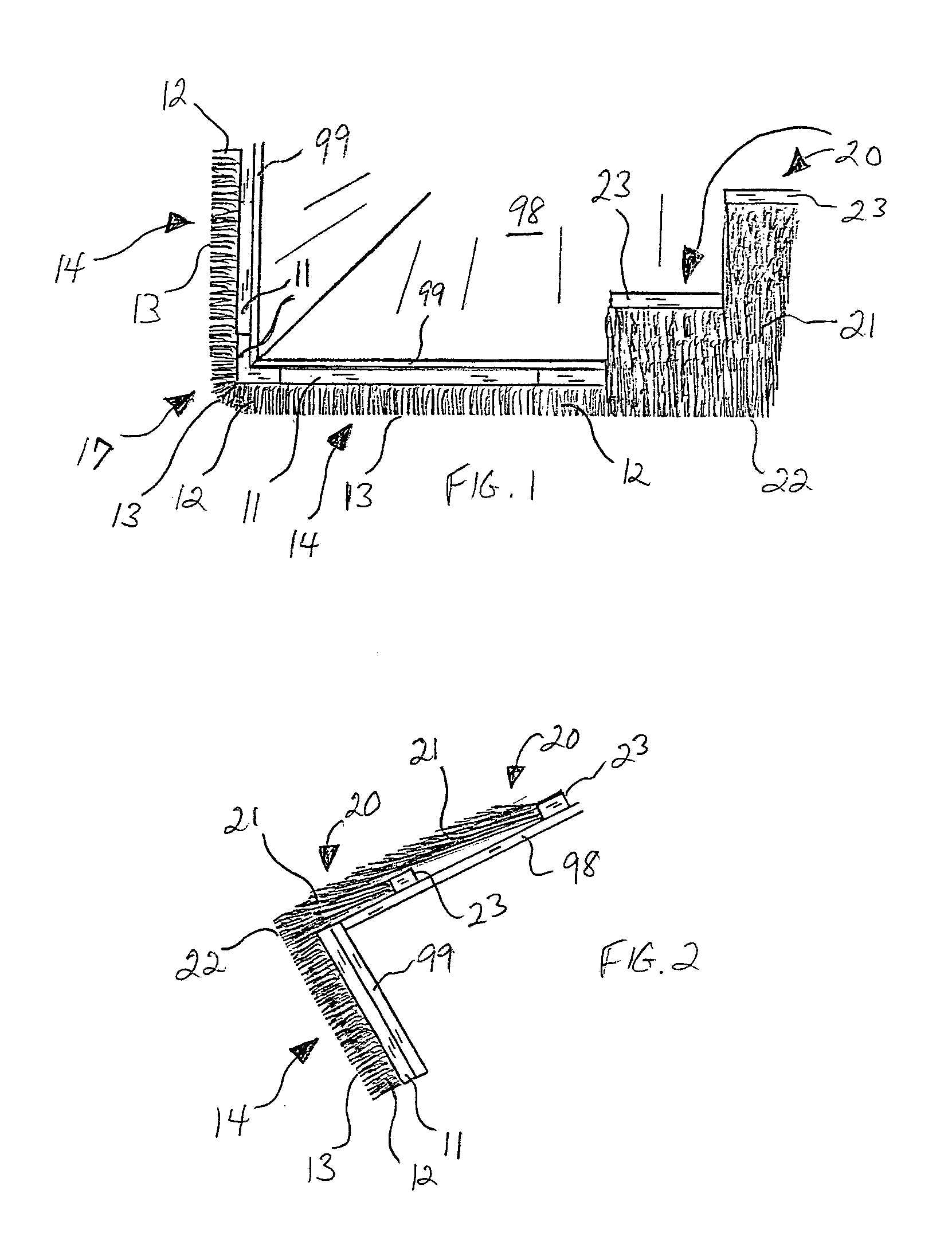

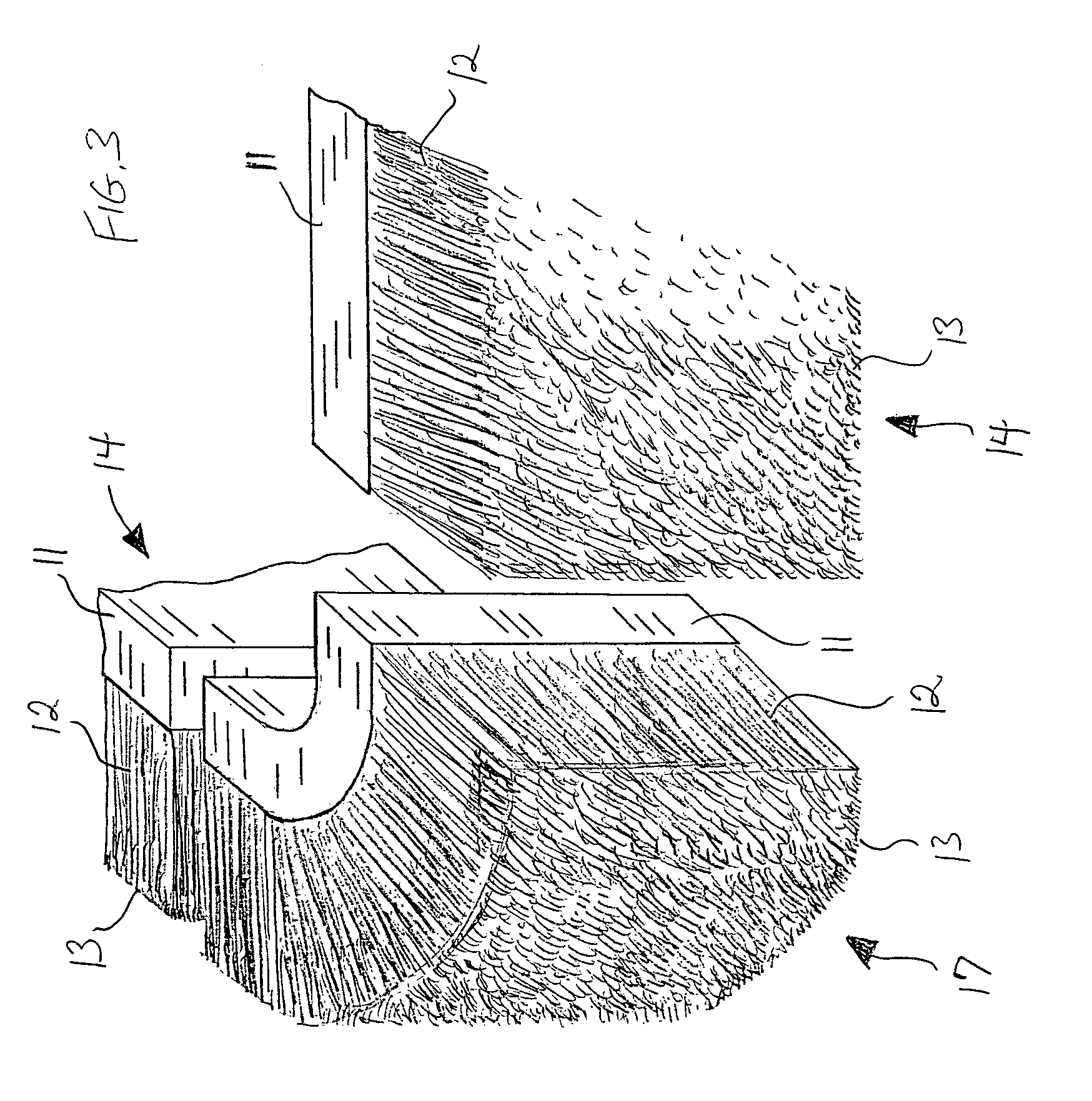

Thatch eave member

A thatch eave member formed of a plurality of individual thatch elements, either natural or synthetic, having a backing member retaining a plurality of individual thatch elements such that the free ends present a generally planar exposed face, wherein the backing member is adapted for attachment along the eave of a roof such that the exposed face matches the ends of a lowermost thatched roofing shingle or roll to give the illusion of a thicker roof, and the system comprising the combination of such eave members and roof members.

Owner:HUBER BARRY RAY +1

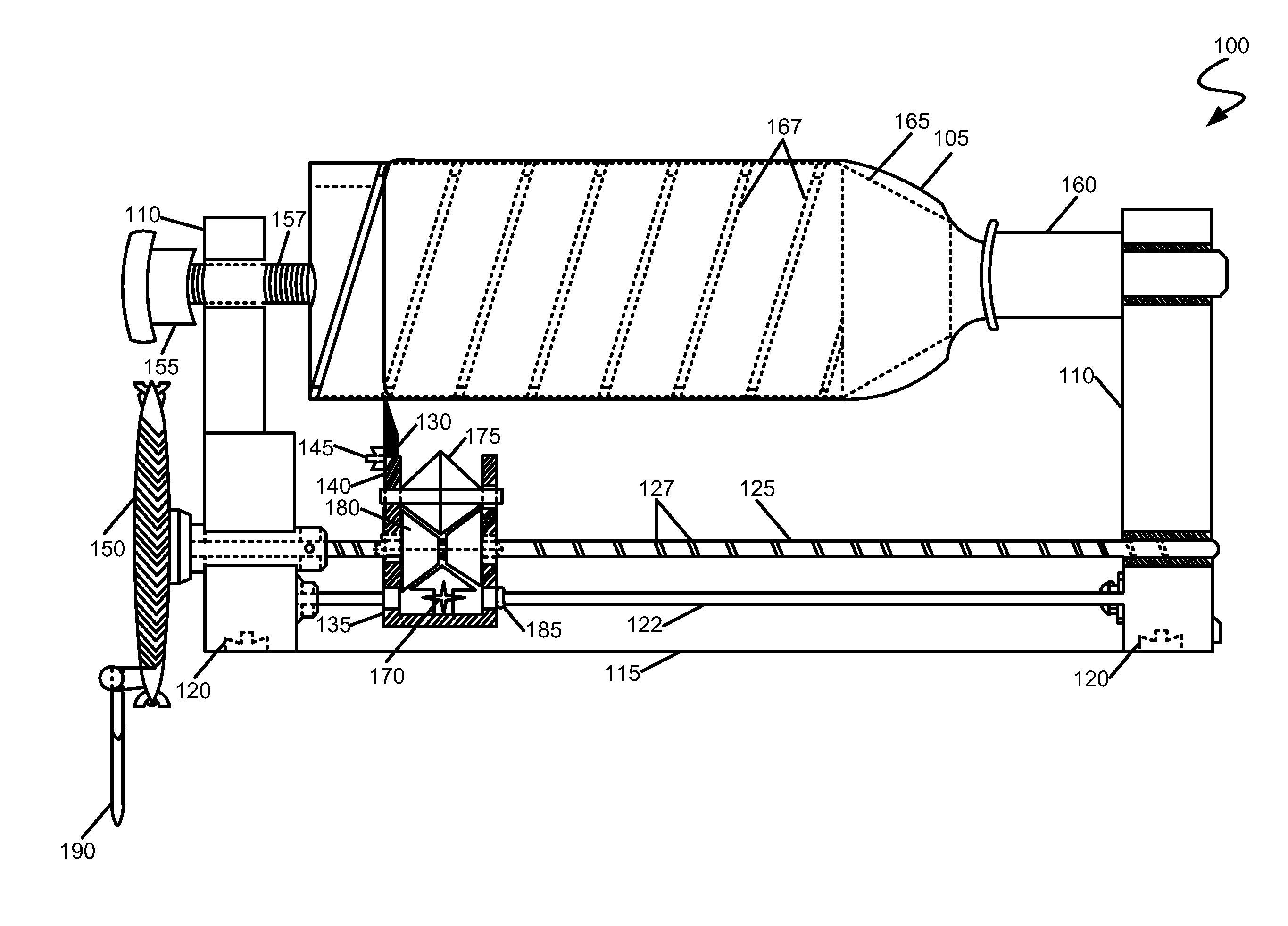

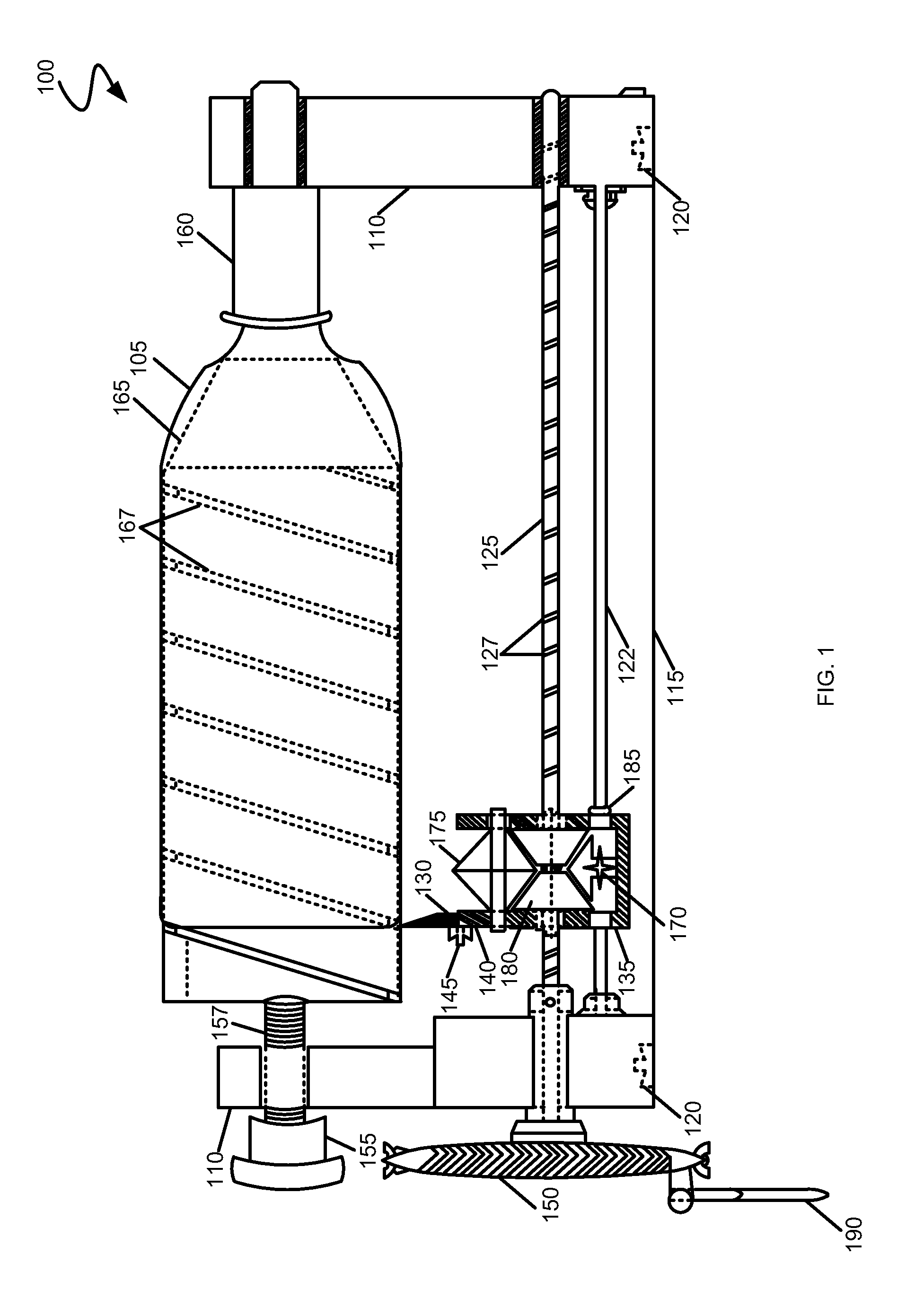

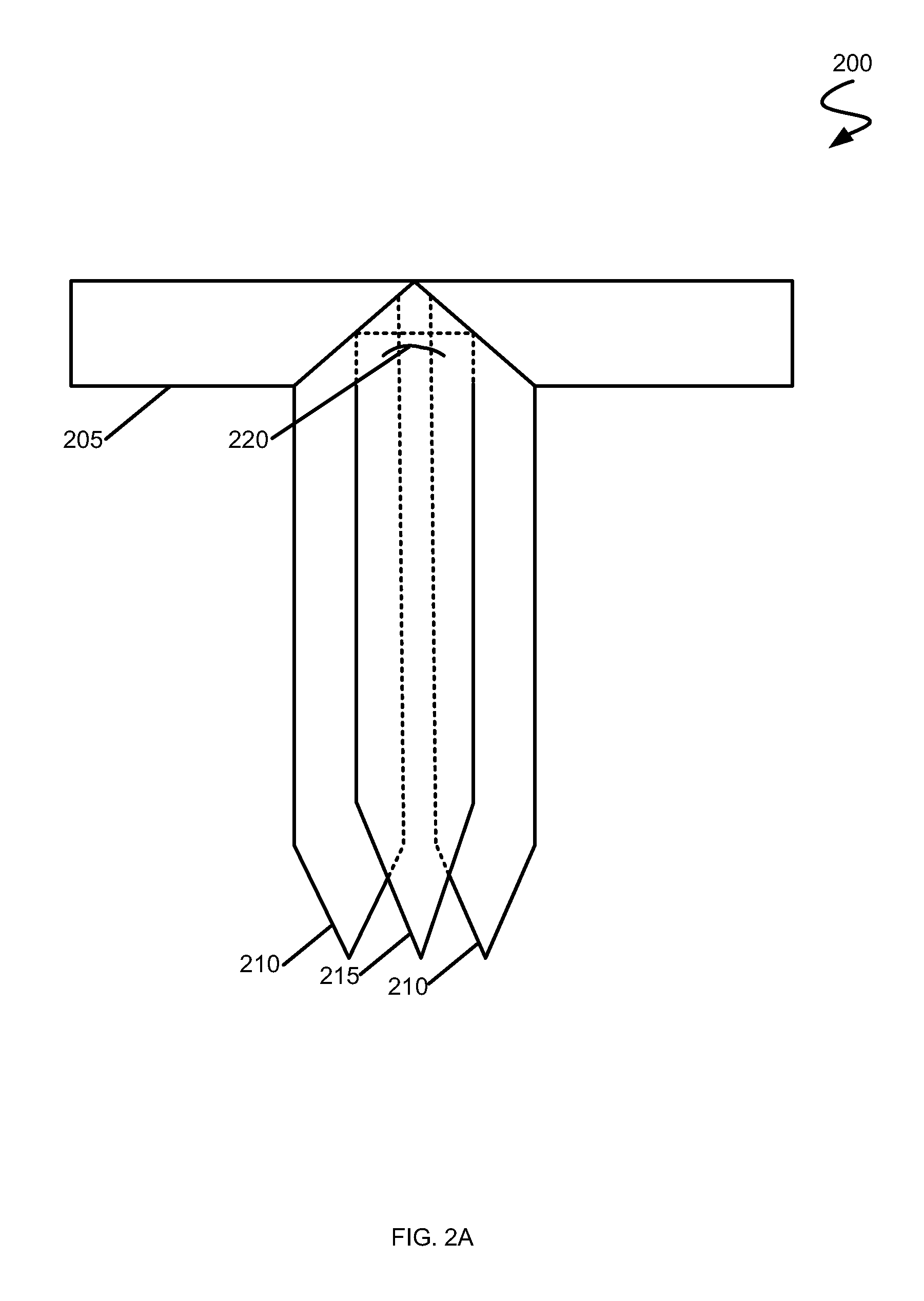

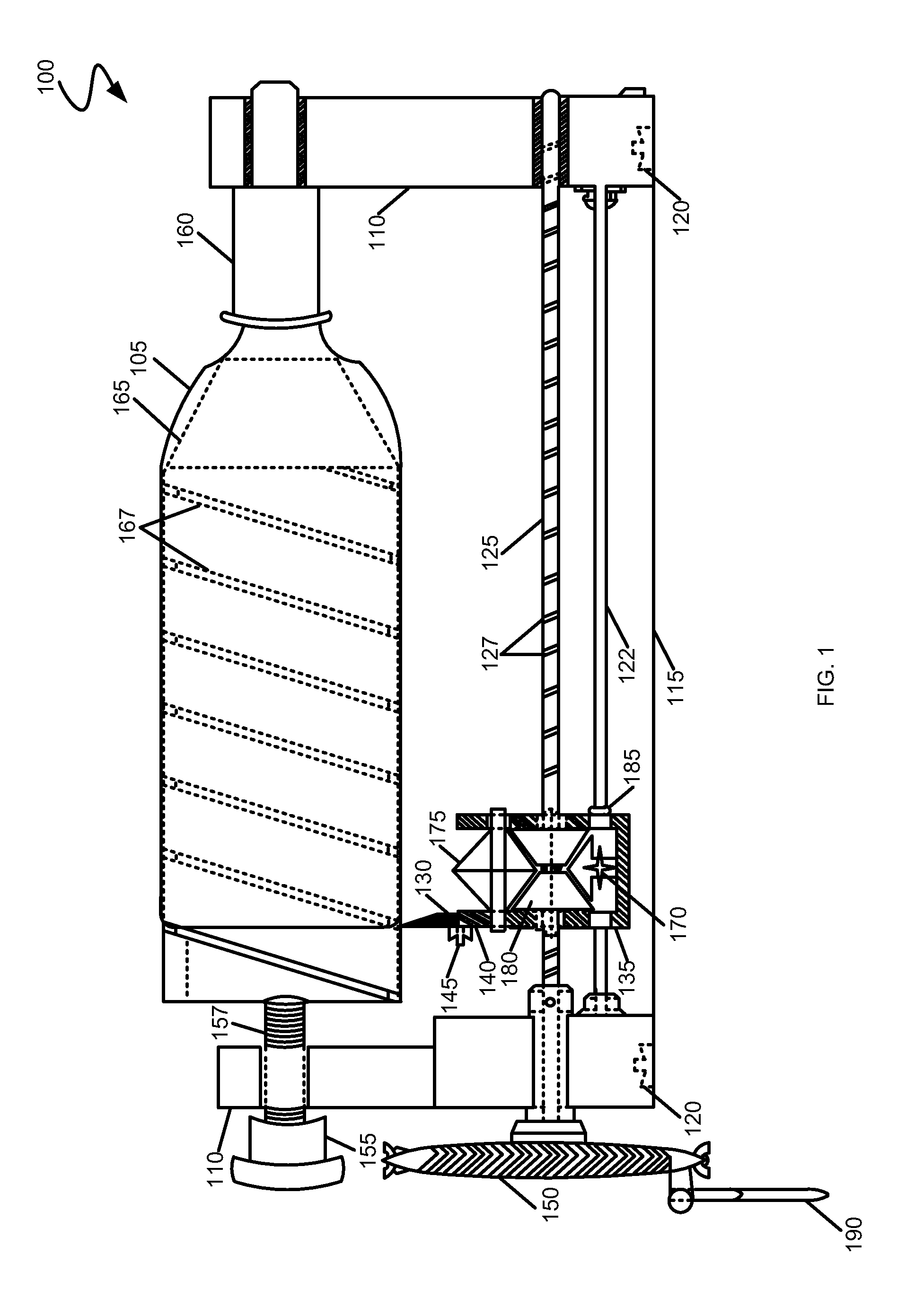

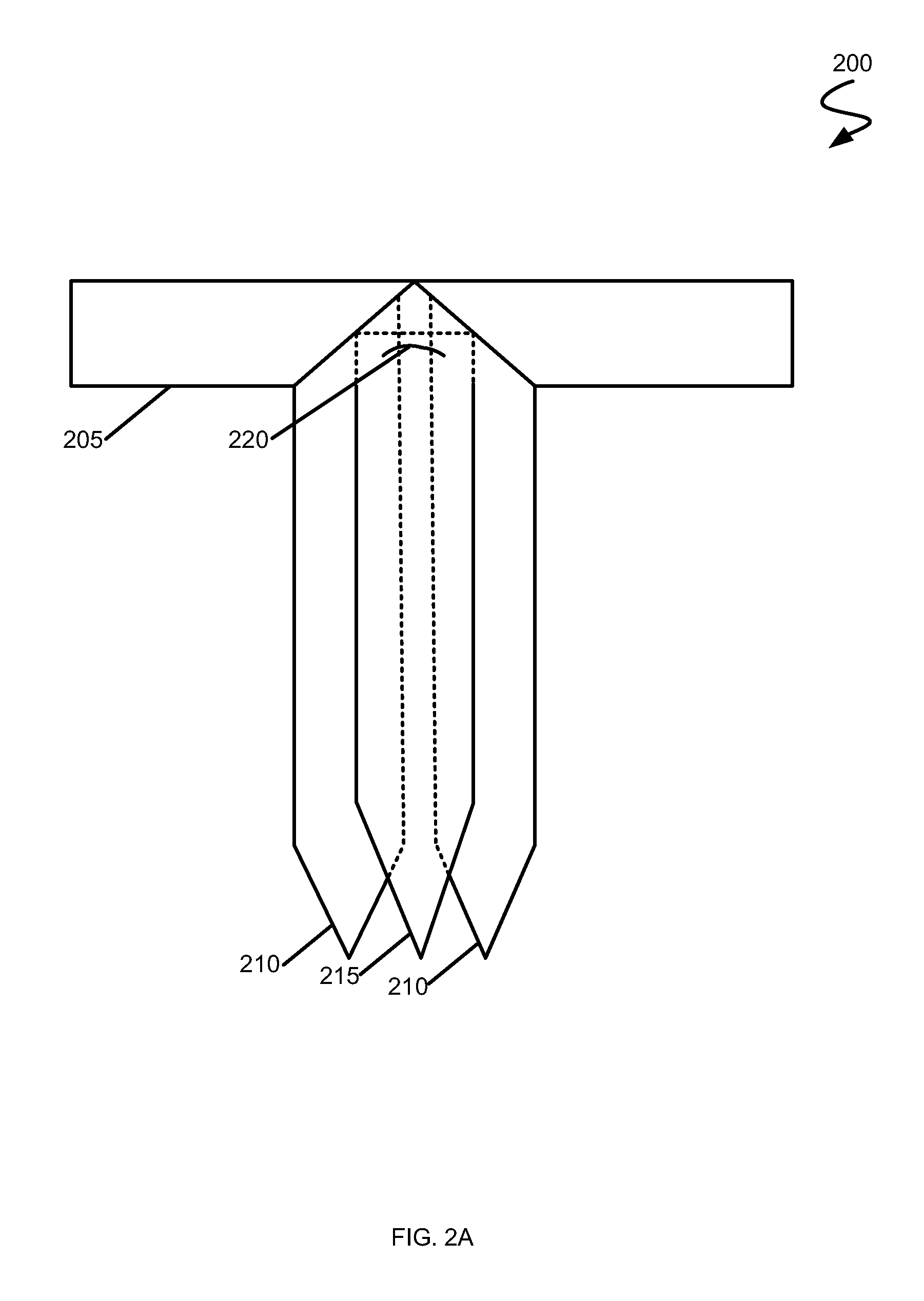

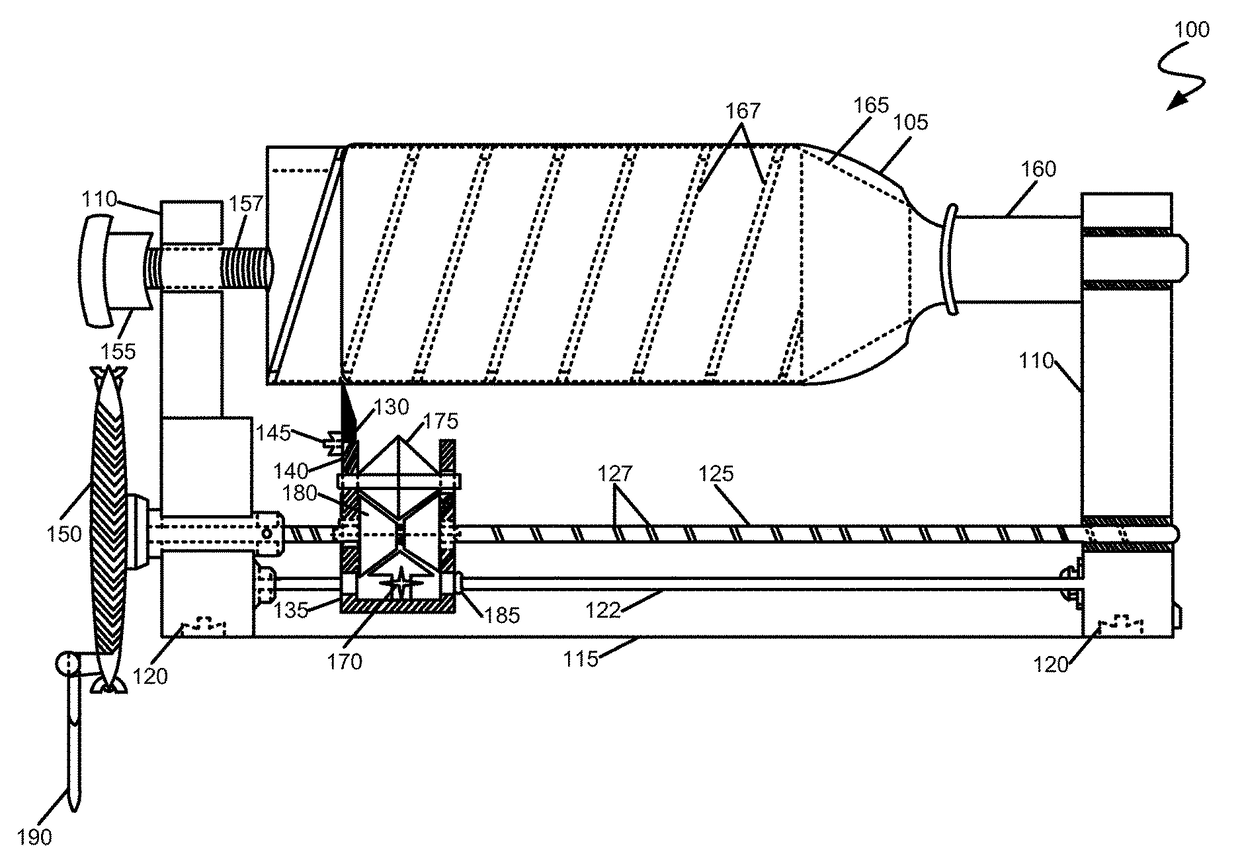

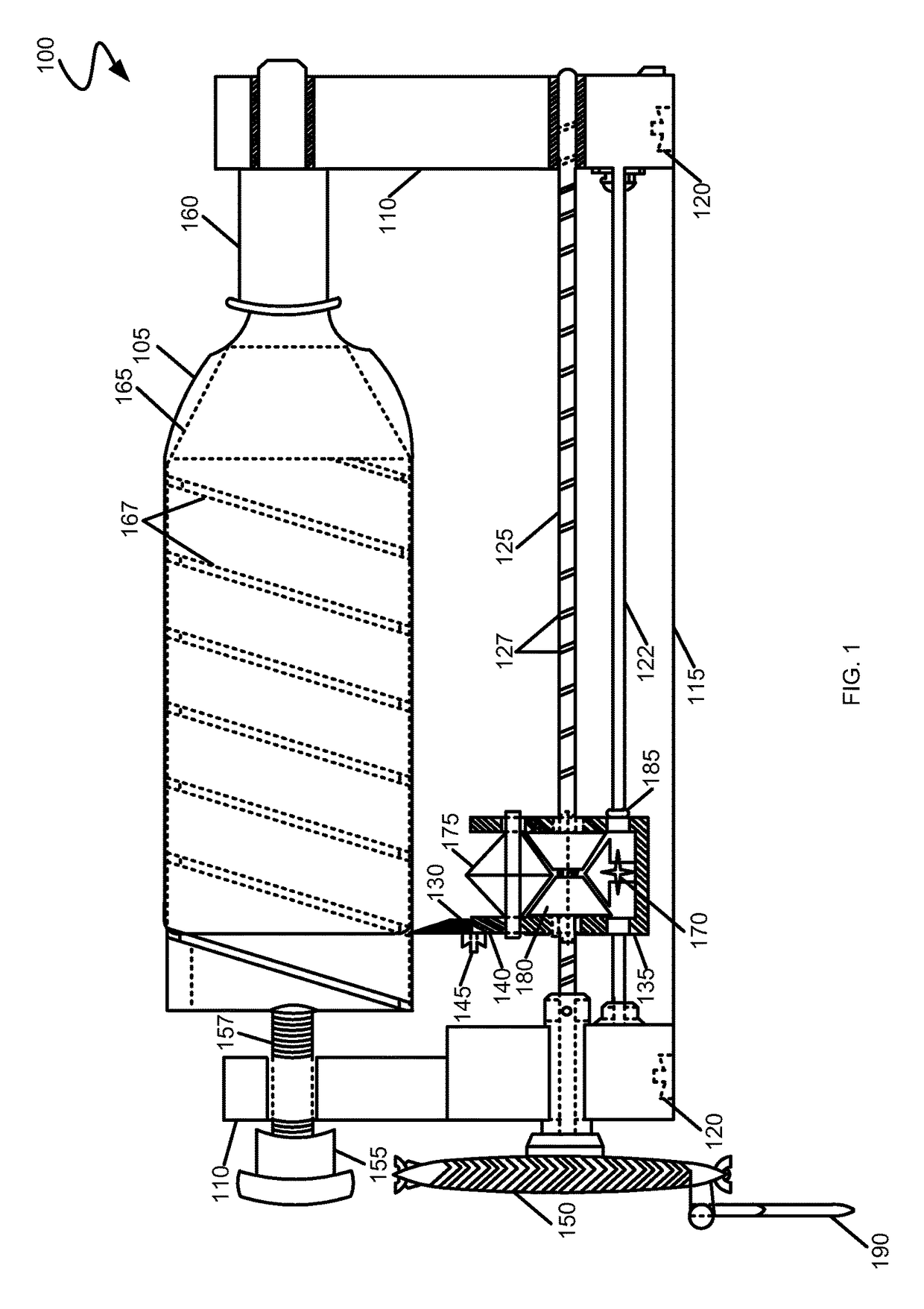

Apparatus and Method for Producing a Thatch Roofing Material for Building Construction

An apparatus and method for producing a thatch roofing material for building construction, the apparatus includes a pair of stanchions, a supporting frame, at least one holding member for holding the container, a first shaft extending substantially perpendicular to each stanchion of the pair of stanchions, and a blade coupled to the first shaft for cutting the container.

Owner:SAIIA DAVID

Simulation thatch tile

InactiveCN102330486AWith thermal insulationFireproofRoof covering using tiles/slatesCovering/liningsThermal insulationPolyvinyl chloride

The invention discloses a simulation thatch tile. The simulation thatch tile comprises a plurality of thatch mustache bodies and further comprises a fixing shaft and a fixing press plate; the thatch mustache bodies are wound on the fixing shaft in a U shape; the fixing press plate is of a U shape and is mounted at the winding end of the thatch mustache bodies; and the thatch mustache bodies are slightly-foamed PVC (polyvinyl chloride) slender strips. The simulation thatch tile disclosed by the invention has the advantages of heat insulation and heat preservation and meanwhile has the characteristics of fire prevention, corrosion resistance, ultraviolet ray resistance without aging, long service life and convenience for mounting, so that the simulation thatch tile can be used for exterior decoration, such as paving the roof and the external walls of a building and the like and can also be applied to interior decoration.

Owner:江苏常盛管业有限公司

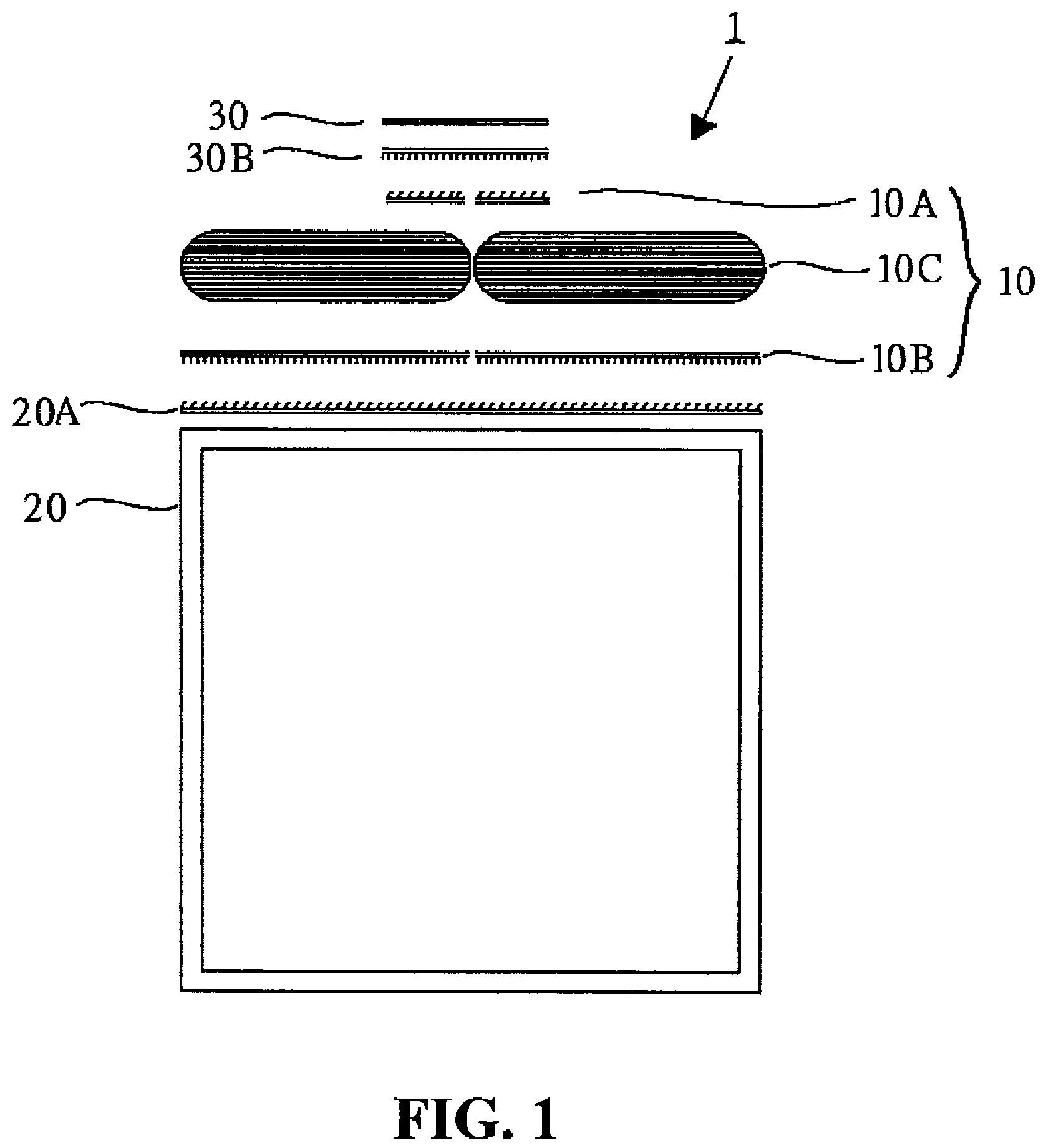

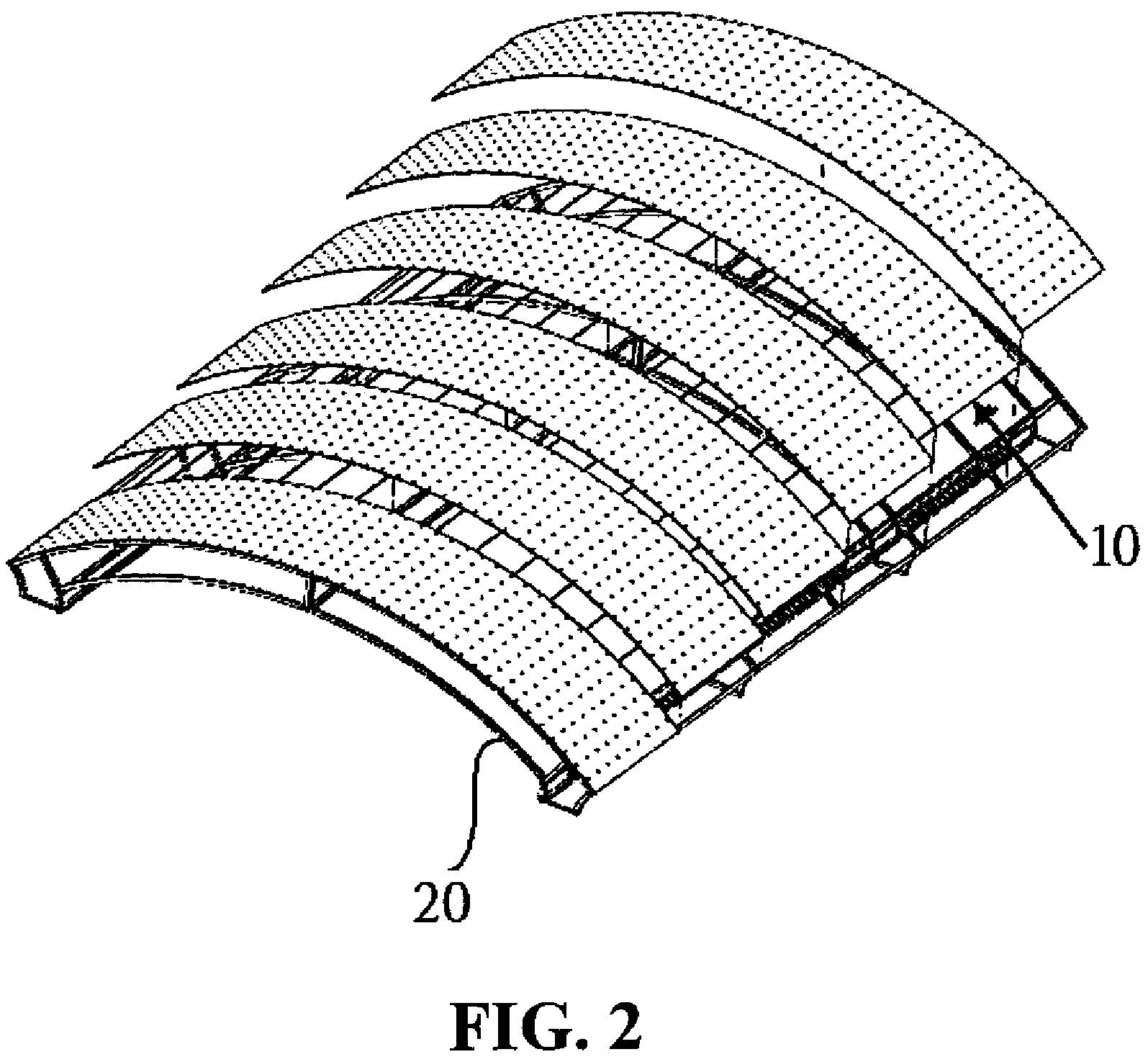

Touch-to-fasten coconut fiber roofing

InactiveUS20100180530A1Improve insulation effectImprove abilitiesRoof covering using slabs/sheetsRoof covering using tiles/slatesFiberEngineering

Disclosed is a touch-to-fastener roofing structure made of coconut fibers, includes: main boards, a support frame arranged below the main boards, a bonding strap arranged on a joint between the main boards. The main board includes an upper touch fastener and a lower touch fastener. The lower touch fastener of the main board engages an upper touch fastener provided on the support frame to fix the main board to the support frame. The upper touch fastener of the main board engages a lower touch fastener provided on the bonding strap to have the joint between the main boards sealed by the bonding strap. The main board includes upper and lower coconut fiber boards, an adhesive plastic film interposed between the two fiber boards for bonding the two fiber boards together, and a main board edge bonding strap fixing exposed edges of the two fiber boards and the film.

Owner:HOMGRADINIA HOME & GARDEN

Apparatus and method for producing a thatch roofing material for building construction

InactiveUS8425390B2Mechanical working/deformationRoof covering using straw/thatchBraced frameEngineering

Owner:SAIIA DAVID

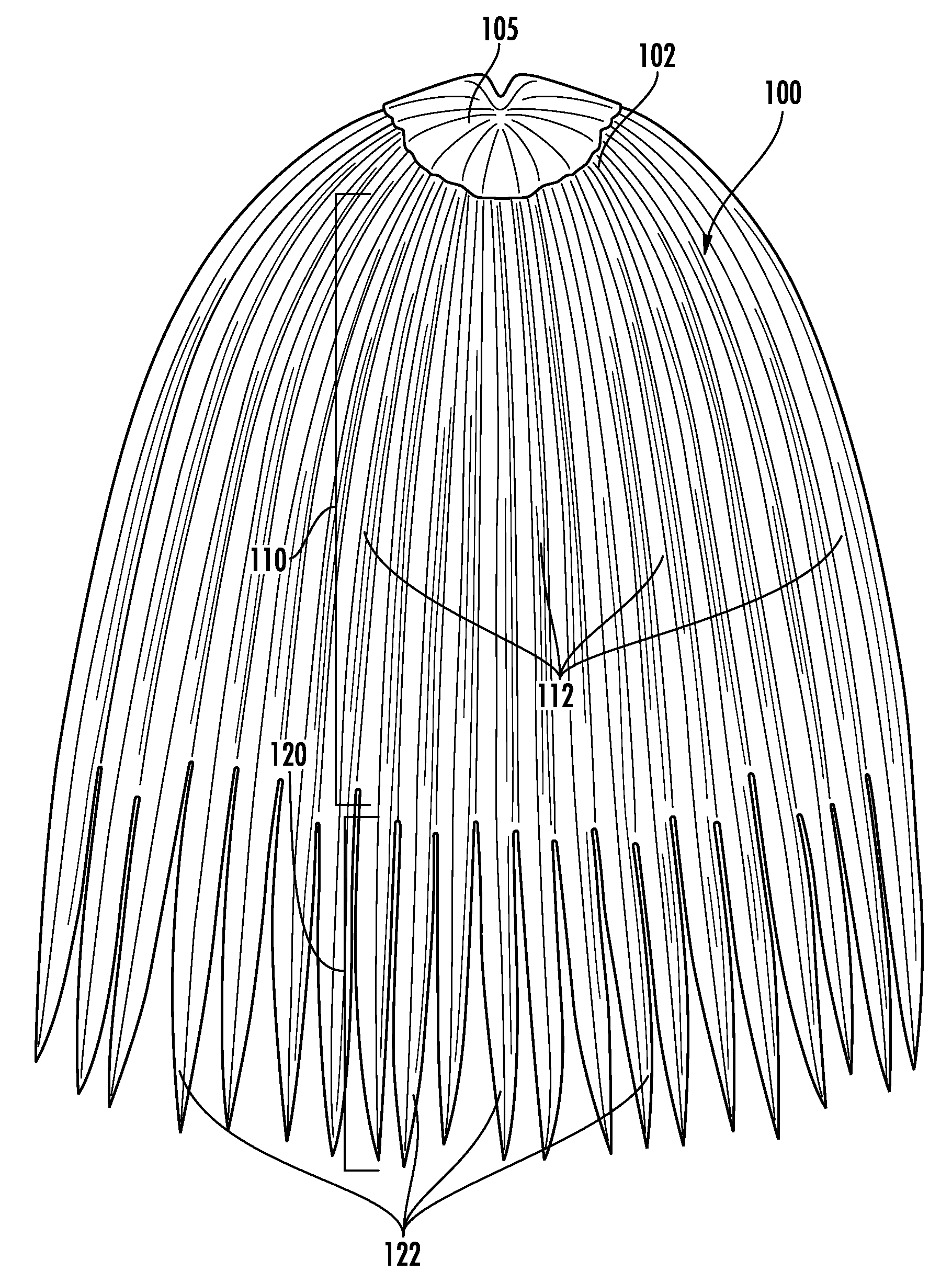

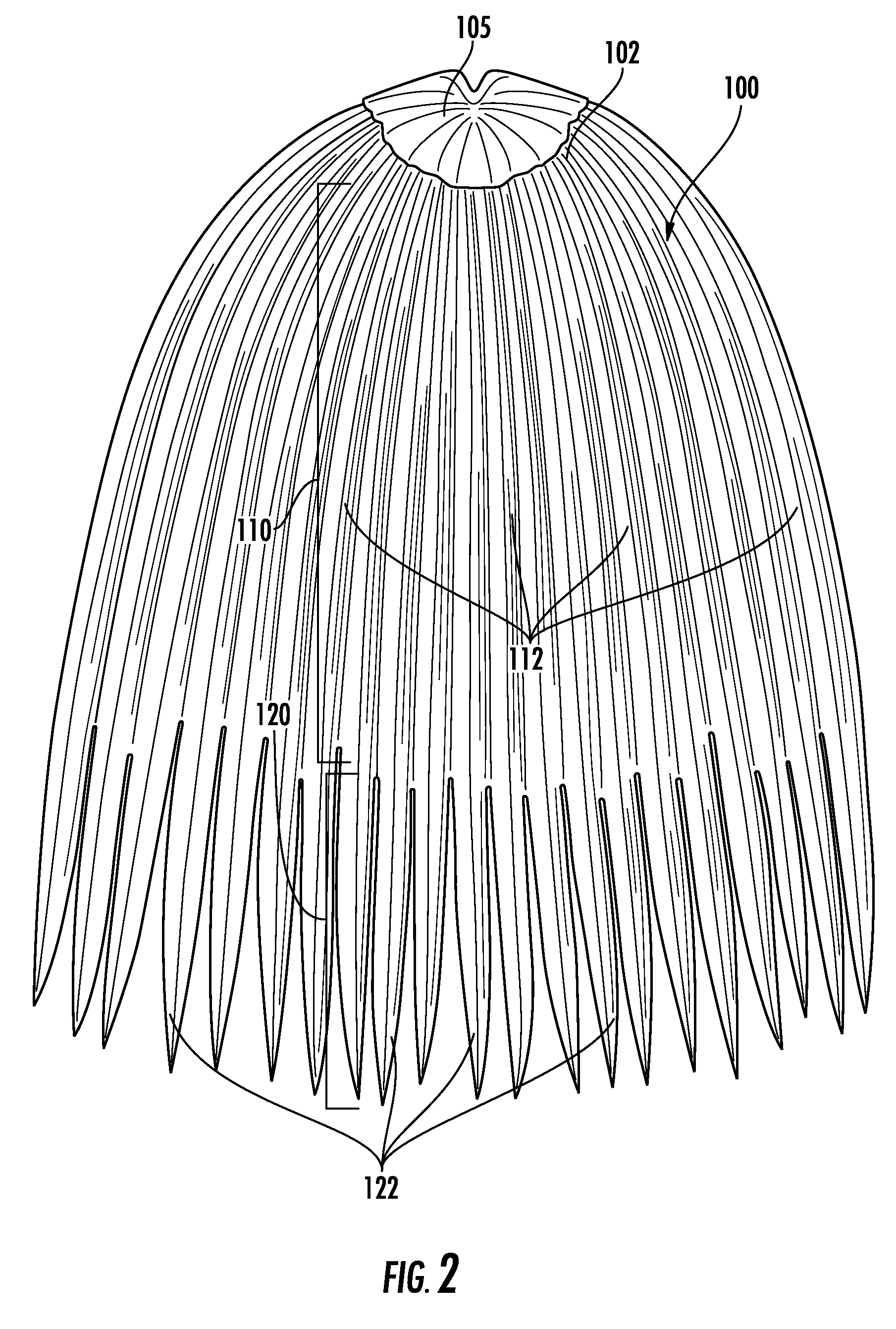

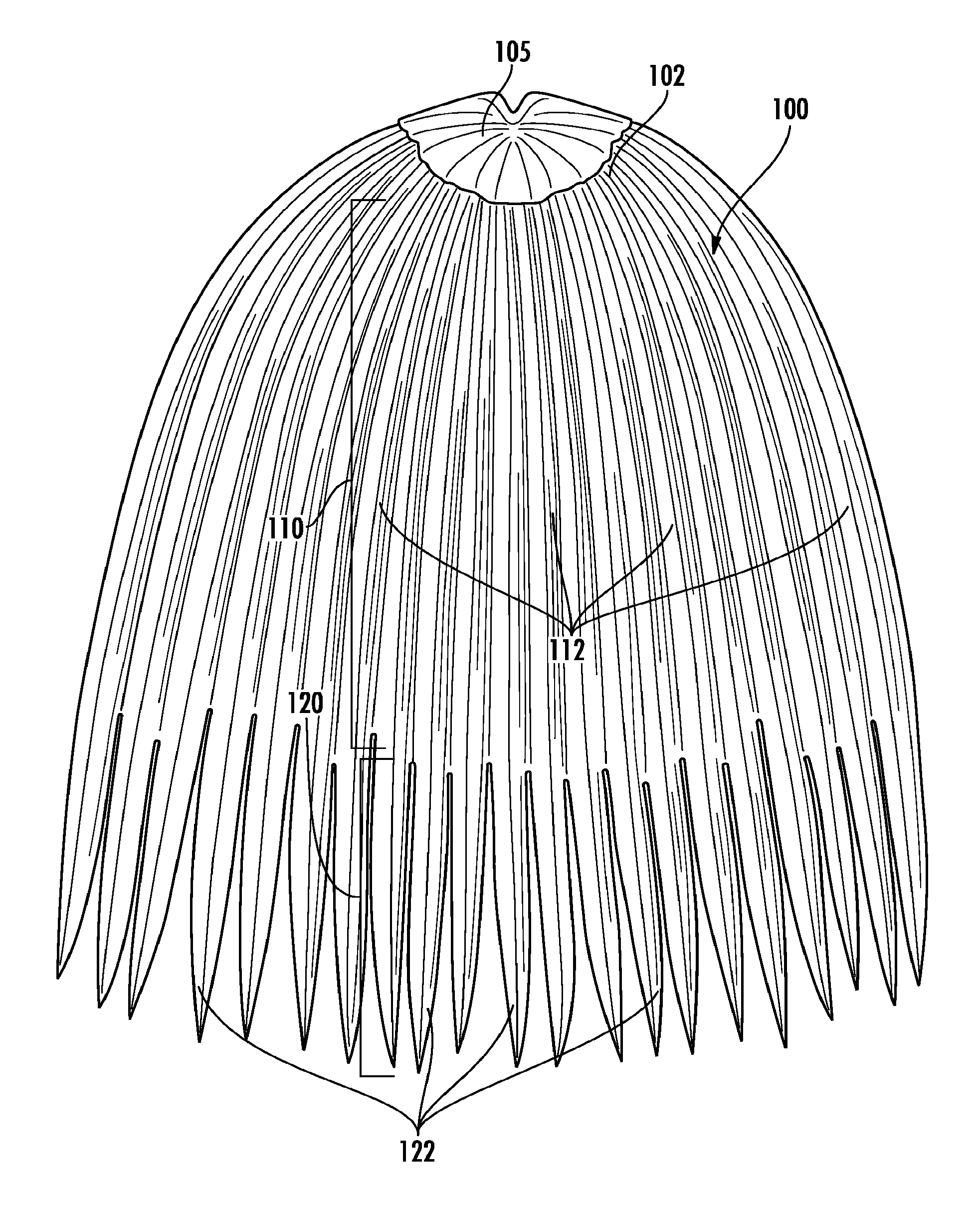

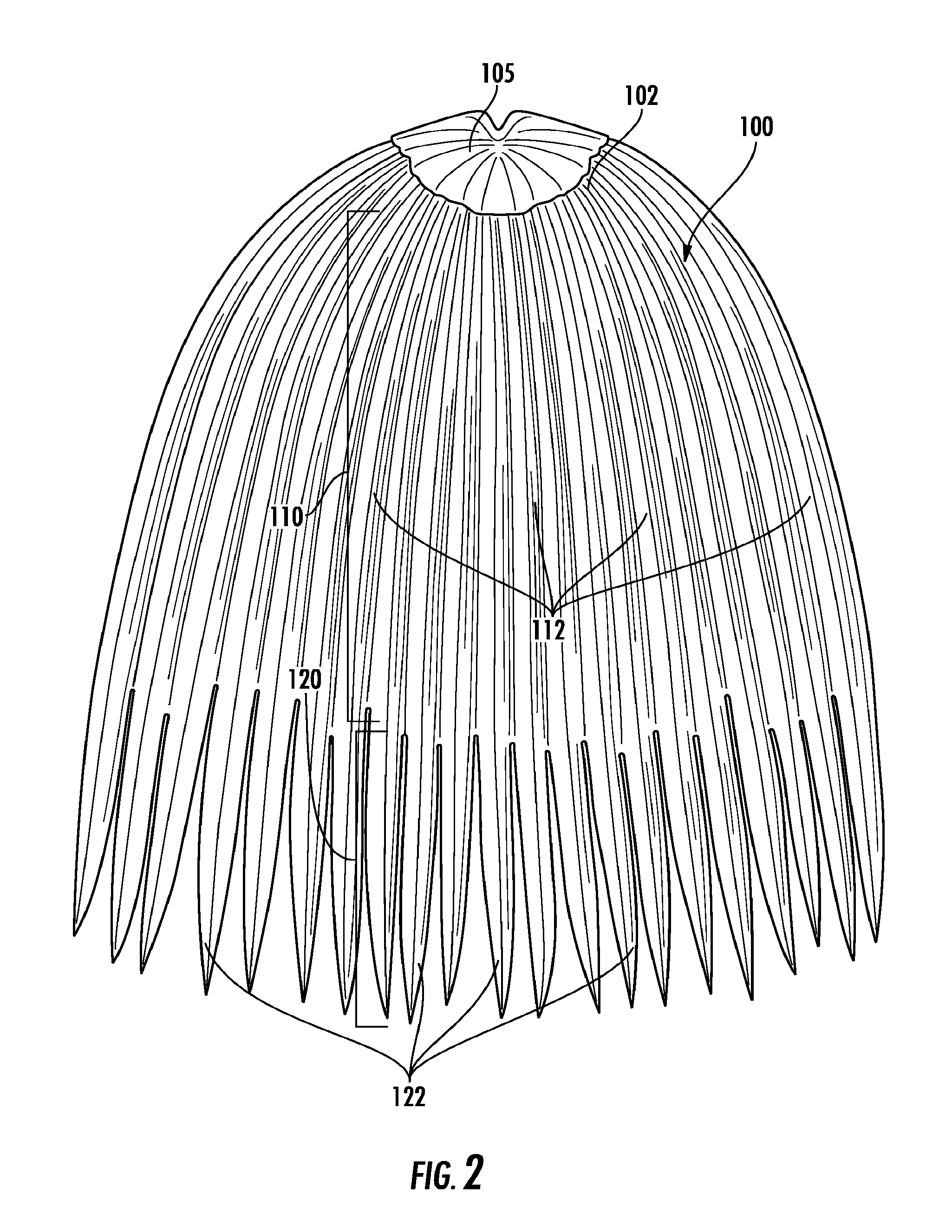

Synthetic thatch members for use as roofing material products and methods of making and using the same

ActiveUS20130255173A1Roof covering using flexible materialsBuilding repairsBiomedical engineeringThree dimensional surface

A synthetic thatch member for use as a roofing material product, along with associated methods for manufacturing and installing the same are provided. The synthetic thatch member comprises: a plurality of frond members defining a first three-dimensional surface of the thatch member and a second three-dimensional surface of the thatch member, the first and second surfaces comprising opposing sides of the plurality of frond members; a fused portion comprising a first portion of each of the plurality of frond members, wherein each of the first portions is connected relative to one another, such that the fused portion defines a substantially impermeable surface; and a serrated portion comprising a second portion of each of the plurality of frond members, each of the second portions being separated relative to one another, such that a plurality of gaps are defined between each of the plurality of frond members.

Owner:PALAPA TECH LLC

Durable natural strip-weaving fabric products

PendingUS20200217010A1Low water absorptionIncreased durabilityStain/soil resistant fibresFencingEpoxyFiber

A natural strip or strip-based weaving or weave fabric product or a natural strip or strip-based woven product is coated and protected with a crosslinking polyvinyl acetate (XPVAc or x-PVAc) adhesive. Said adhesive is applied and cured on the exterior surfaces of said product as a first coating layer or a primer in combination with a coating layer of acrylic, alkyd, asphalt, epoxy, latex, polyurethane, silicone coatings, urethane, vinyl ester, etc. coated over the cured adhesive as a second coating layer or a topcoat. Said product is woven or fabricated with stalks, stakes, staves, stems, sticks, strands, shoots, splints, straws, strings, twigs, bark, branches, laths, leaves, rods, roots, whicker, etc. of a fiber plant, a tree, or a crop, or the combination thereof.

Owner:LU ZIQIANG

Method for laying natural thatch tiles for old village houses of Va nationality of Wengding

Owner:昆明市建筑设计研究院股份有限公司

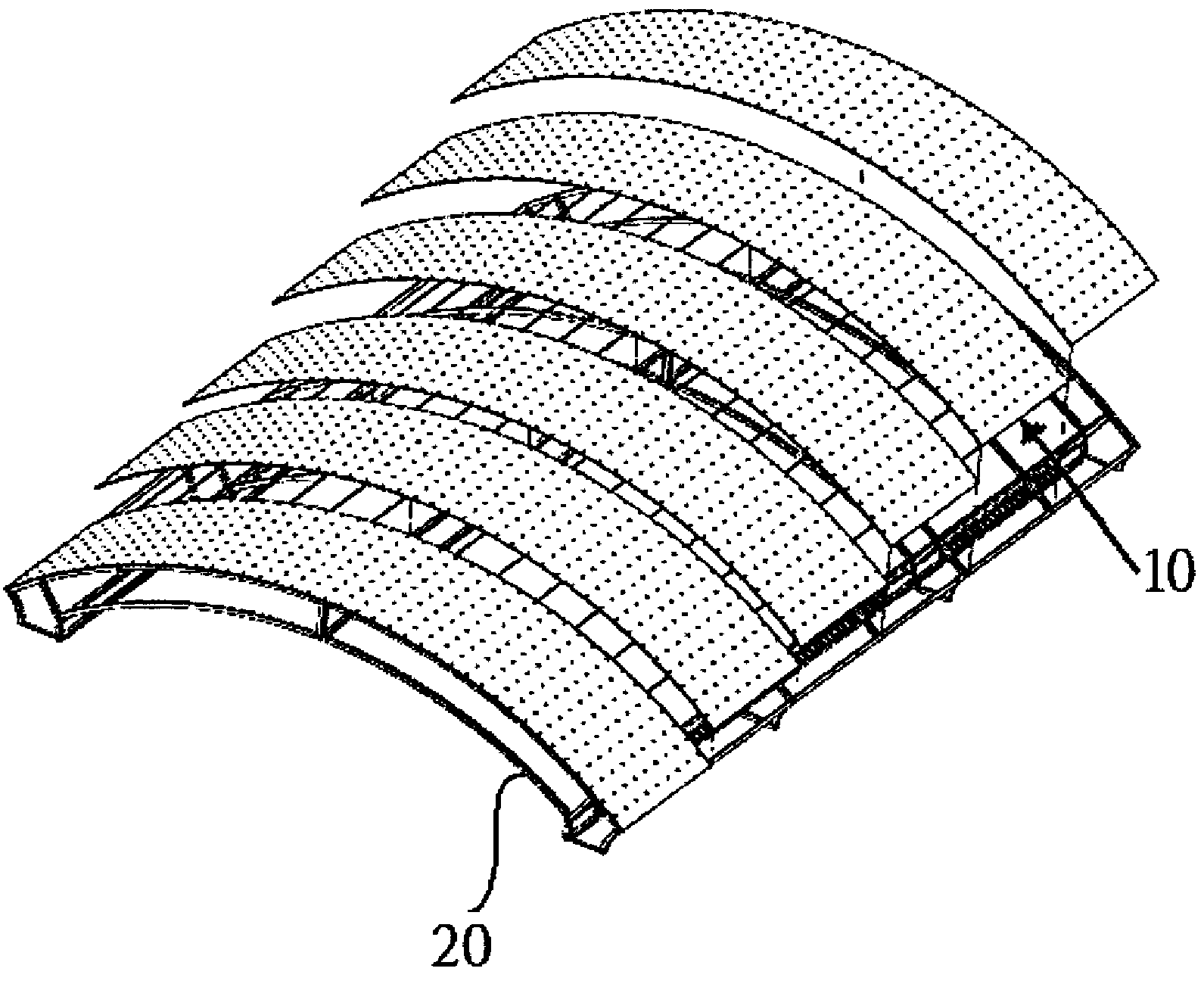

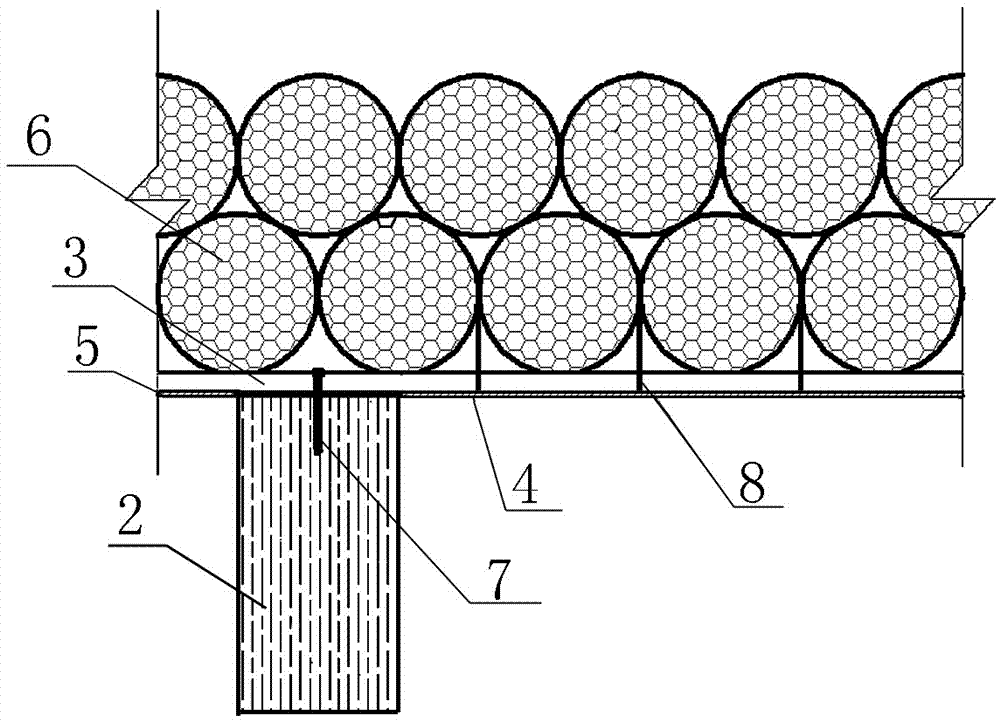

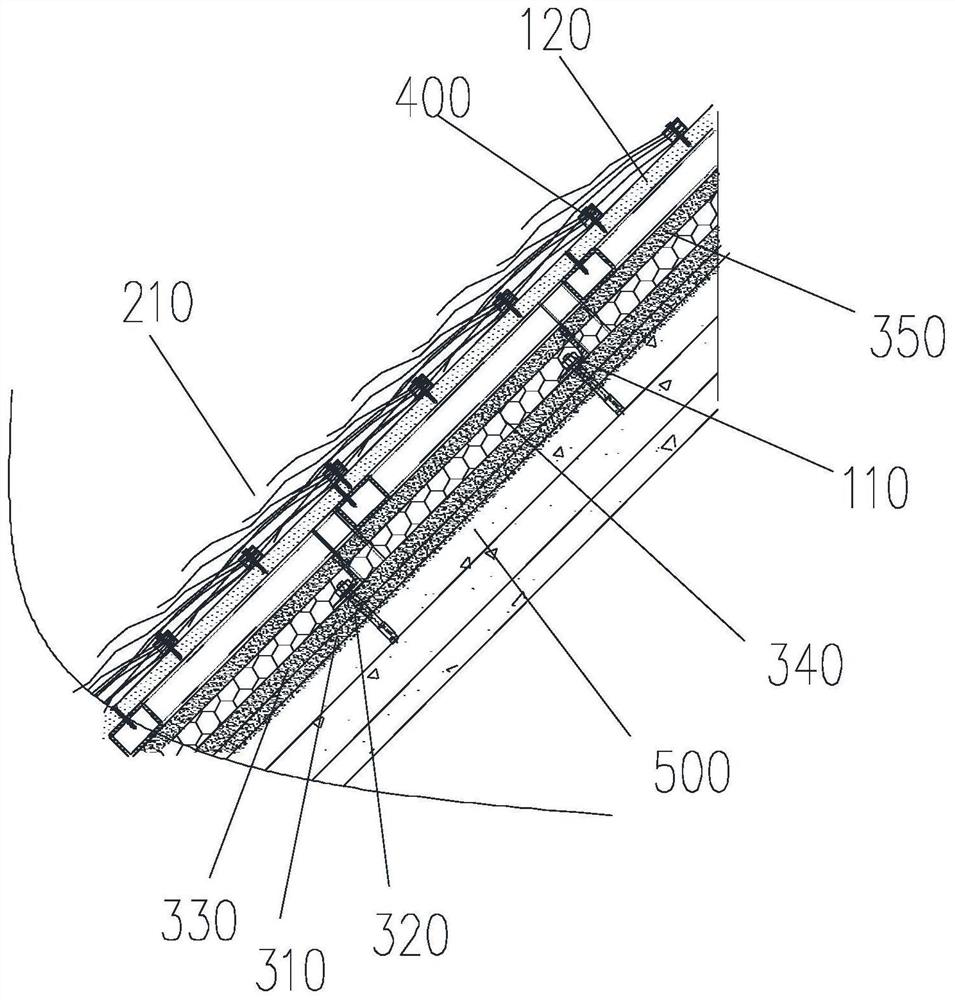

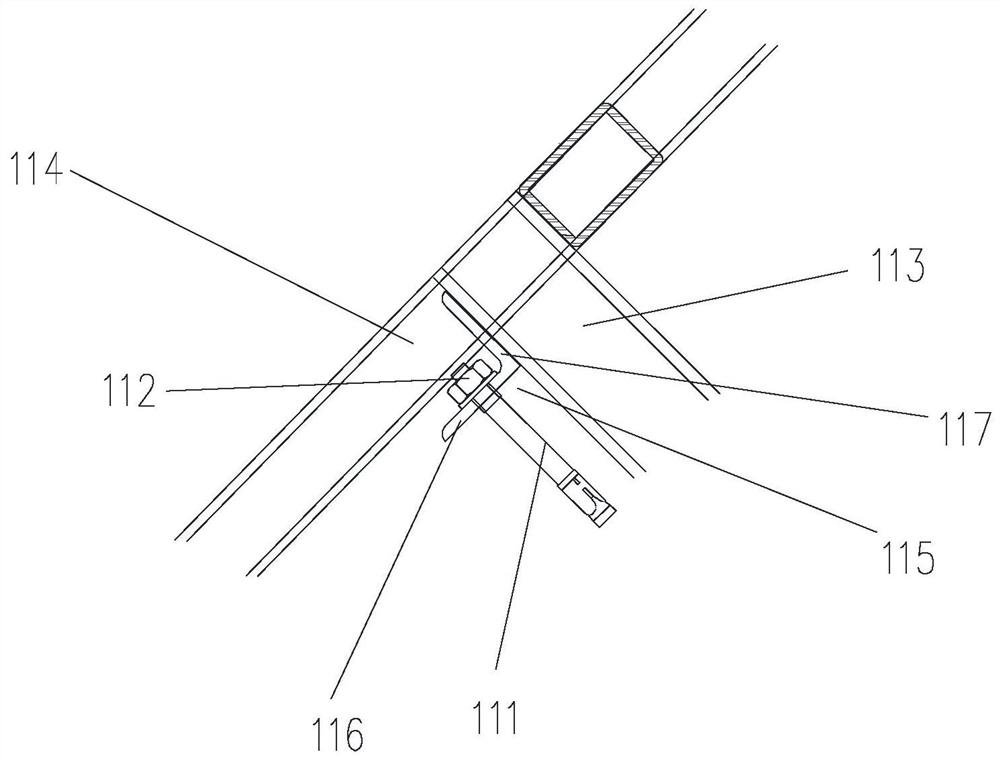

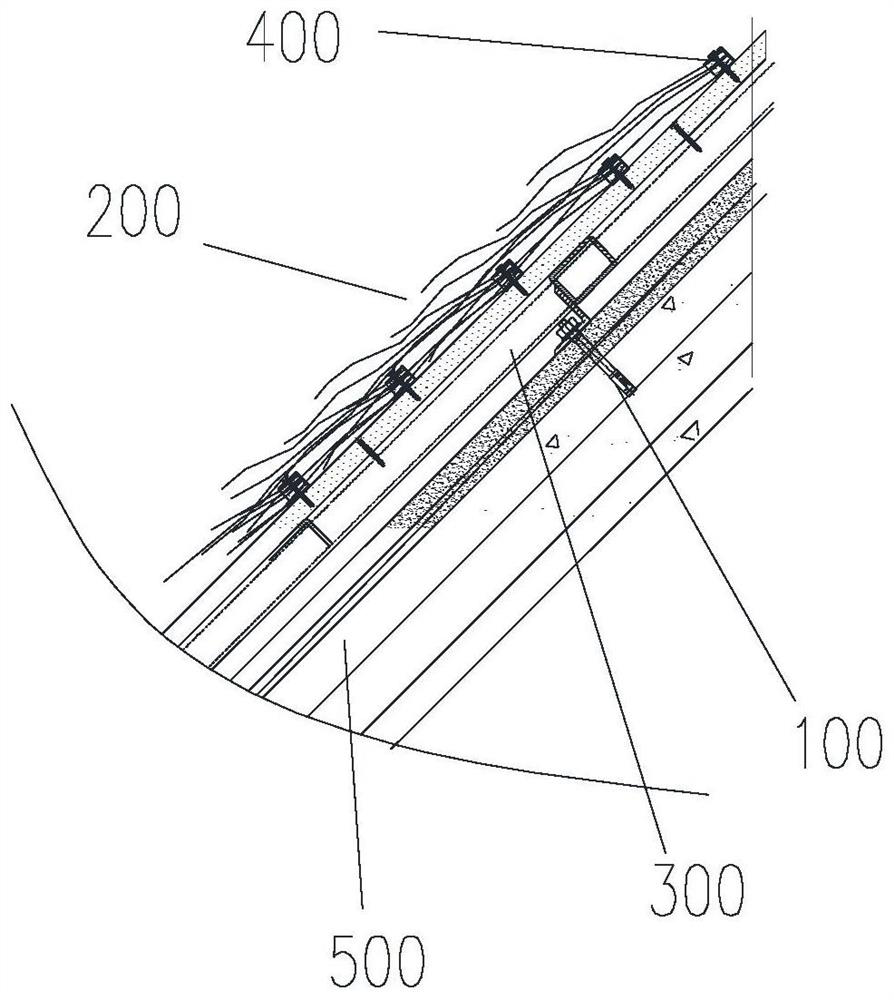

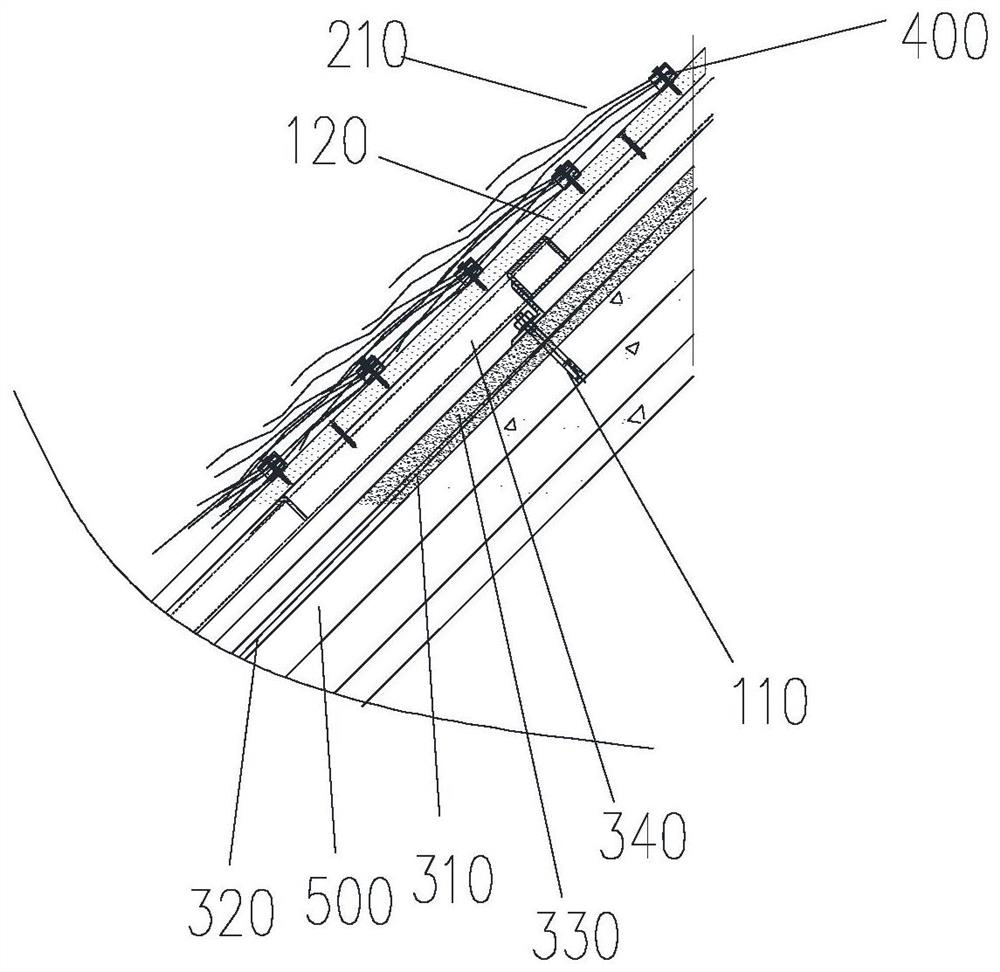

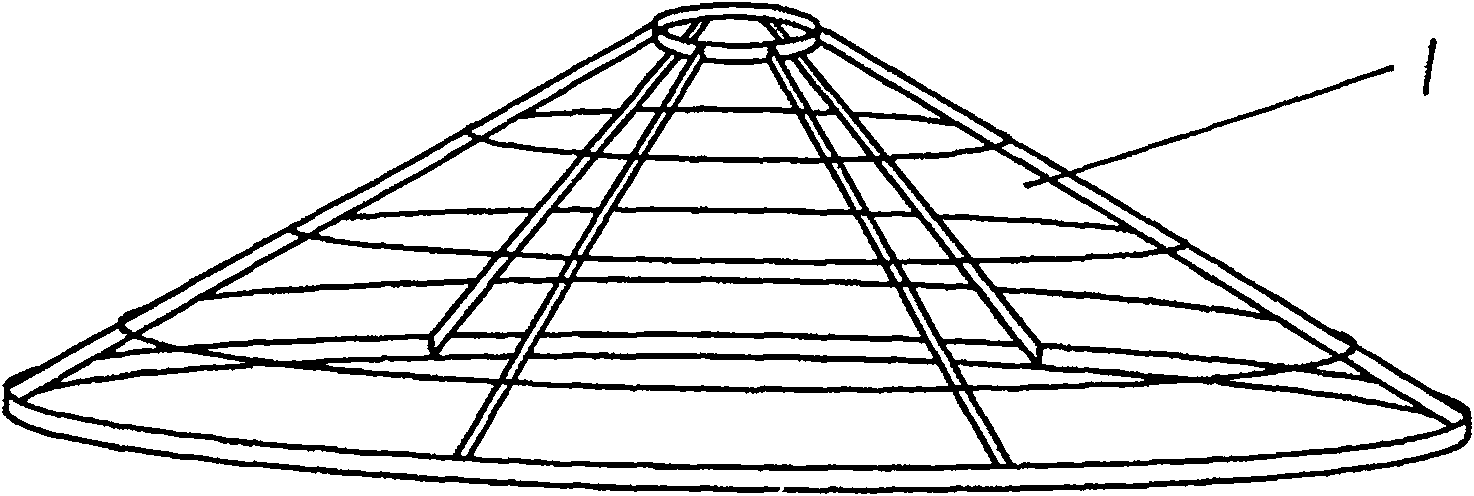

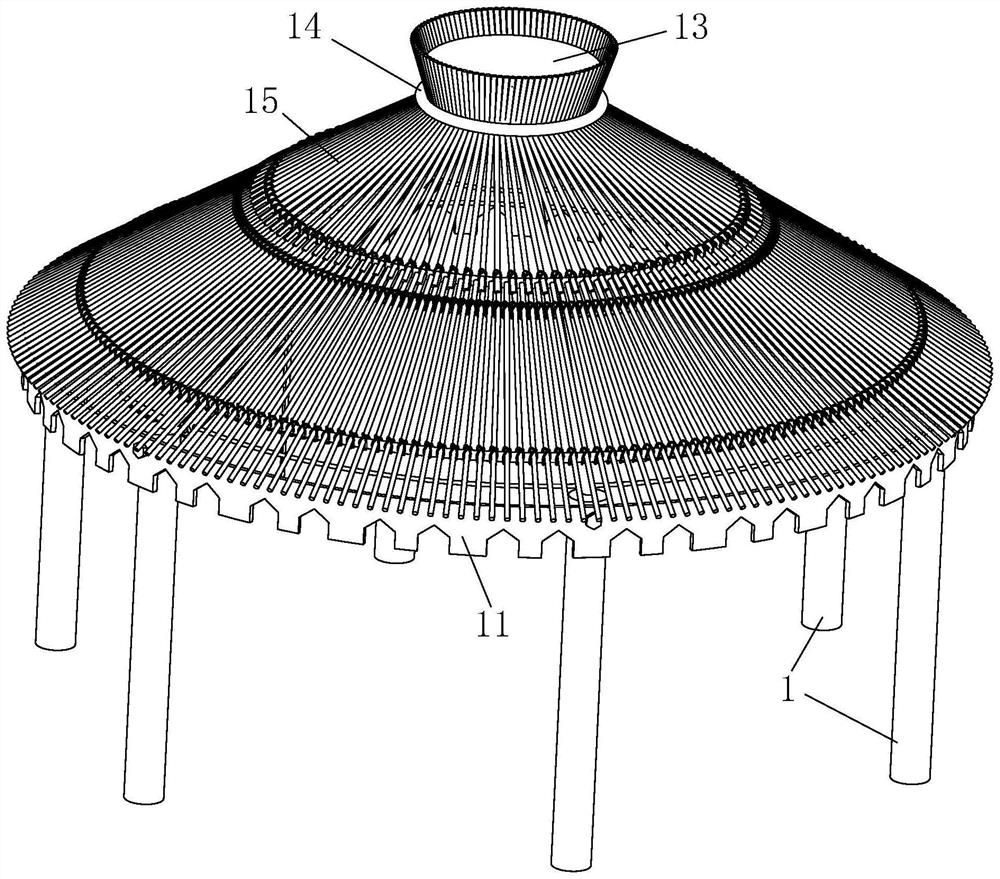

Hidden keel thatch roof structure and construction method

InactiveCN107299726AImprove carrying capacityIndoor look and feel effect is goodRoof covering using straw/thatchPurlinKeel

The invention discloses a hidden keel thatch roof structure and a construction method. The hidden keel thatch roof structure comprises one group of horizontal annular keels, one group of horizontal annular supports, a lining thatch layer and an outer thatch woven curtain layer, the horizontal annular keels are parallelly looped outside a roof truss structure along the long axis direction of a slanting purlin at intervals, the horizontal annular supports are parallelly looped outside a roof truss structure along the long axis direction of the slanting purlin at intervals, the lining thatch layer is woven in the horizontal annular supports and the horizontal annular keels, the horizontal annular supports support on the bottom surface of the lining thatch layer, the horizontal annular keels press the top surface of the lining thatch layer, one group of thatch woven curtains are sequentially paved along the inclined direction of the roof truss structure to form the thatch woven curtain layer, and the upper thatch woven curtain presses the upper end of the lower thatch woven curtain in two adjacent thatch woven curtains. The hidden keel thatch roof structure solves the technical problems that a traditional thatch roof is coarse and poor in compactness and bearing capacity, and attractiveness and application conditions are difficultly met.

Owner:CHINA CONSTR FIRST BUREAU GRP INTERIOR FITOUT ENG +1

Synthetic Roofing Shingle

InactiveUS20140220266A1Roof covering using tiles/slatesDead plant preservationRoof tileSolid surface

A monolayer synthetic or artificial thatch shingle comprising a plurality of tapering extensions extending from a base flange member, the thatch shingle having been formed from a thin sheet of stiff plastic, and the extensions having been formed by removing material from the thin sheet. The base flange member presents a solid surface, such that when shingles are overlaid in successive rows advancing up the pitched roof, the combination of overlapping base flange members provides a water barrier such that all rain water is directed from the slanted roof.

Owner:HUBER ABRAM

Eave structure

PendingCN111794452AStrong aestheticsImprove waterproof performanceRoof covering using slabs/sheetsBuild-up roofsEavesStructural engineering

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Eave structure

PendingCN111794451AUnique ornamentalStrong aestheticsRoof covering using slabs/sheetsBuild-up roofsEavesEngineering

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

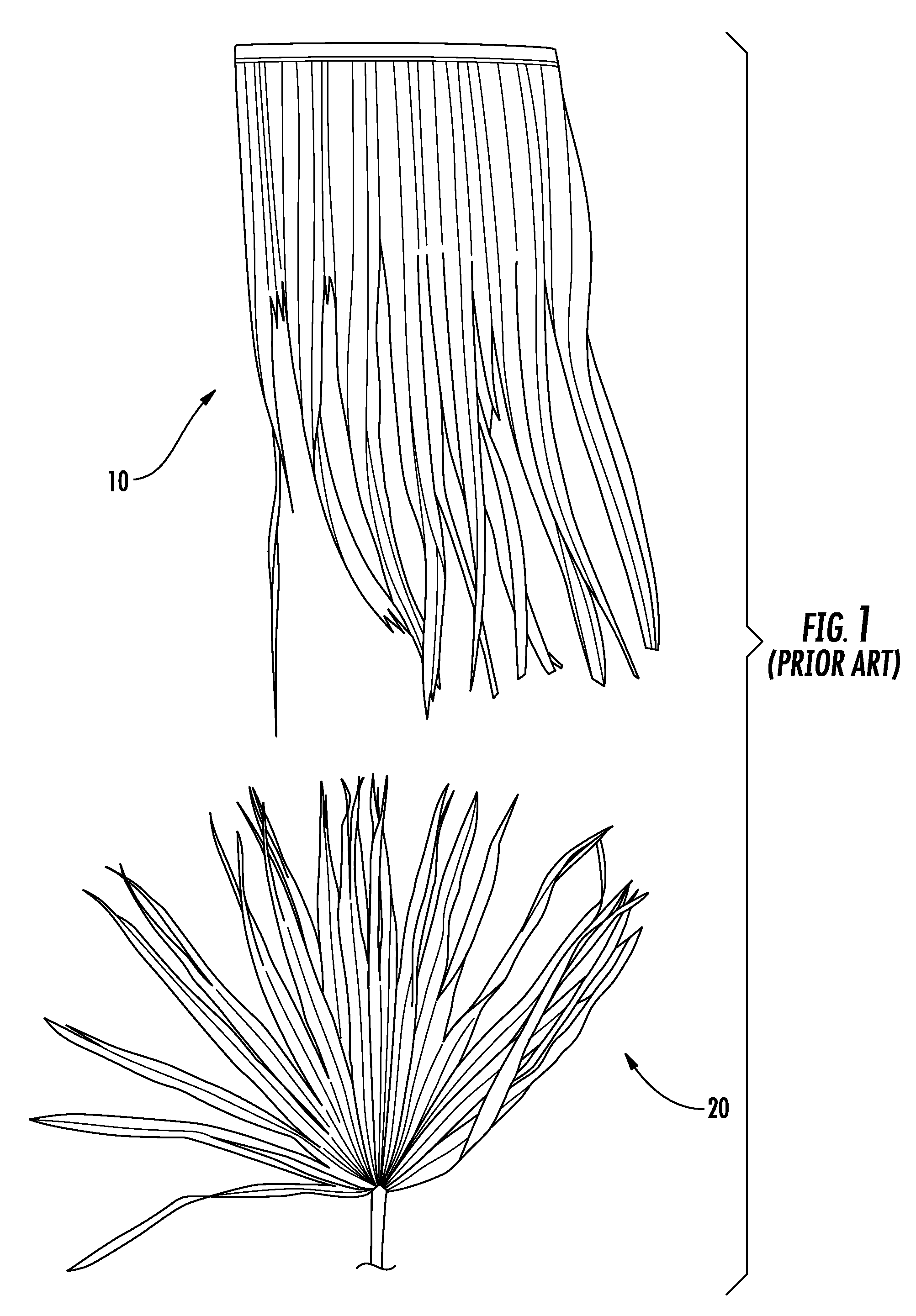

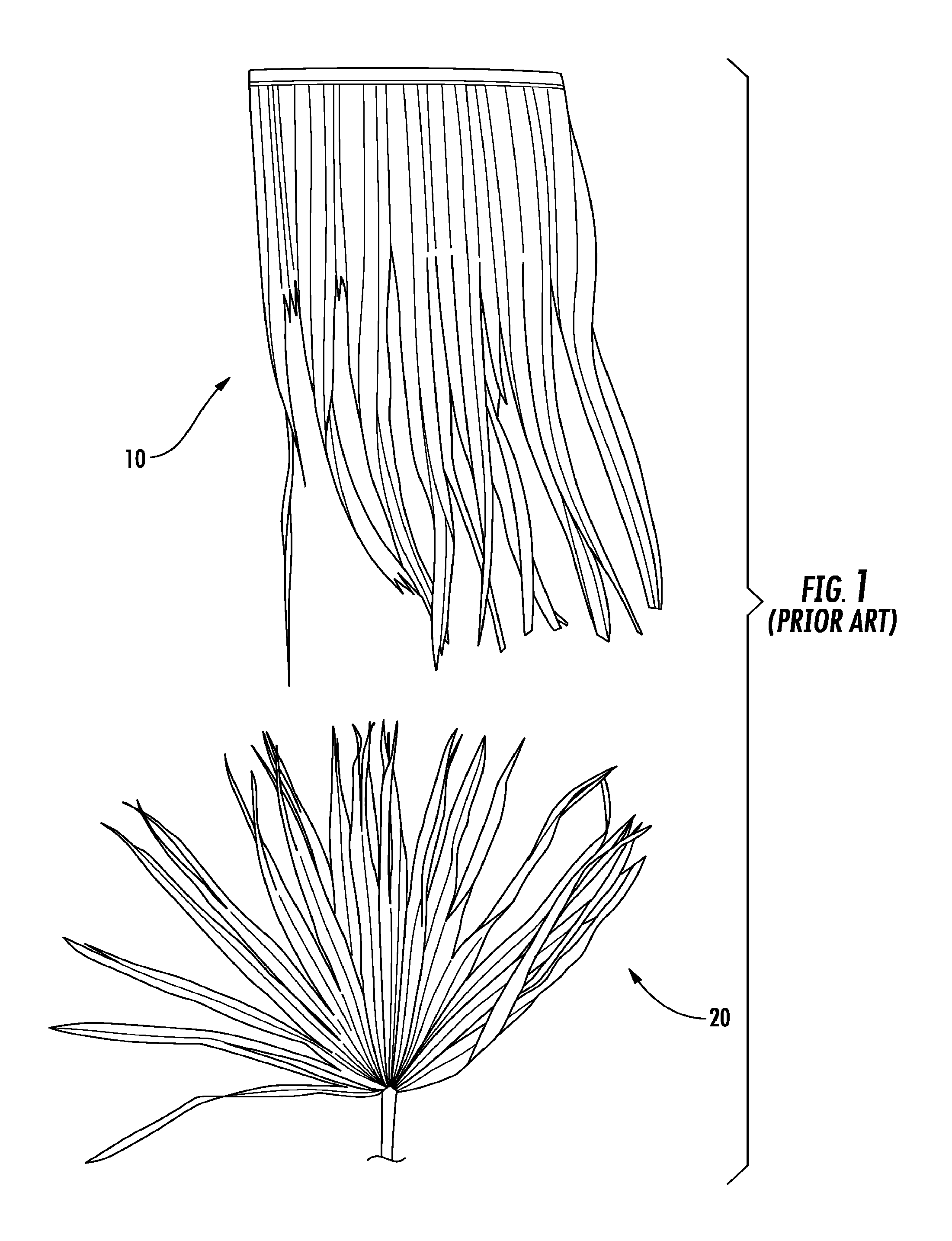

Procedure to manufacture palm roof tiles for rustic roofs and the obtained product

InactiveUS7900415B2Faster and expeditious systemRoof covering using tiles/slatesBuilding repairsEngineering

Provided herein are compositions for palm tile, which consists of an assembly of leaves of the palm tree Brahea dulcis, previously torn, placed in a uniformly and symmetrically way and lengthwise sown, stapled or held to the part where the petiole meets the lamina to form a tile, board, panel or Hawaiian skirt. Also provided herein are methods to manufacture the tiles and elements for its elaboration and placement on crosspieces of a structure.

Owner:GARCIA AZCUE ARMANDO CARLOS

Roofing tile or wall body member and production method thereof

InactiveCN102852286ARainproofAntisepticRoof covering using tiles/slatesConstruction materialSurface layerCorrosion resistant

The invention relates to a roofing tile or wall body member. The roofing tile or wall body member is weaved by at least one wattle. The roofing tile or wall body member comprises an entity portion which is weaved by the wattle and a beard portion, the entity portion comprises an upper surface layer and a lower surface layer, and a functional film layer which is attached to the upper surface layer and the lower surface layer and has functions such as heat insulation, ventilation, impact resistance, thunder resistance and leakage resistance is arranged in the middle between the upper surface layer and the lower surface layer. The invention relates to a production method of the roofing tile or wall body member. The roofing tile or wall body member is provided with the functional film layer, then the roofing tile or wall body member has rainproof and corrosion-resistant effect, and the color of the roofing tile or wall body member can simulate couch color such as couch yellow and grass green. The roofing tile or wall body member is attractive in color, light in weight, free from decay and insects, durable, low in cost and convenient to install. The roofing tile or wall body member is an ideal building material which simulates natural plant roofs and walls. Besides, the roofing tile or wall body member feels natural and simple.

Owner:HONGKONG MINGYU INDAL

A method of laying natural thatch tiles for houses in ancient villages of Wengding Wa people

Owner:昆明市建筑设计研究院股份有限公司

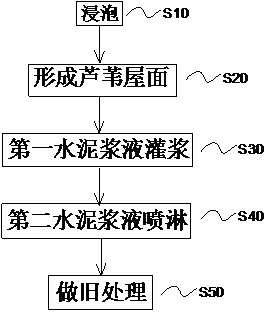

Fireproof and corrosion-resistant distressing method for reed roof

PendingCN114683367AGuaranteed appearanceWeight increaseRoof covering using straw/thatchReed/straw treatmentCement groutFire retardant

The invention discloses a fire-proof anti-corrosion distressing method for a reed roof. The fire-proof anti-corrosion distressing method comprises the following steps that S10, a reed material is soaked in a flame retardant solution; s20, a reed roof with the required thickness is formed above the roof; s30, grouting treatment is conducted on the interior of the reed roof; and S40, second cement grout is sprayed to the surface of the reed roof. The reed material is of a hollow structure, and the reed material is soaked in a flame retardant solution, so that the interior and exterior of the reed material have flame-retardant effects; through grouting treatment, the first cement grout is adhered to the outer side of the reed material and used for protecting the reed material and preventing water from directly contacting the reed material, so that an anti-corrosion effect is achieved, and a fireproof effect is achieved; the first cement grout increases the weight of the reed roof and enables the reed roof to be firmly fixed on the roof. And second cement grout is sprayed on the surface of the reed roof, so that a layer of second cement grout is adhered to the reed material on the surface, the anti-corrosion and fireproof effects are achieved, and the appearance of reeds is kept.

Owner:DECAI DECORATION

Synthetic thatch members for use as roofing material products and methods of making and using the same

ActiveUS8984836B2Roof covering using tiles/slatesRoof covering using flexible materialsBiomedical engineeringThree dimensional surface

Owner:PALAPA TECH LLC

Thatch roofing system

Owner:DOYLE BRENDAN

Thatch-imitated roof construction method

PendingCN113585581AImprove construction qualityImprove the overall look and feelBuilding roofsRoof covering using straw/thatchSocial benefitsFalsework

The invention discloses a thatch-imitated roof construction method. The thatch-imitated roof construction method comprises the steps of positioning and setting out, foundation pit excavation, base treatment, scaffold erection, steel structure embedded part welding, concrete pouring and maintenance, waterproof mortar plastering, steel keel skeleton roof welding, imitation thatch laying and the like. The method is convenient to construct, firm and durable, accurate in control over the distance between the upper-layer imitation thatch and the lower-layer imitation thatch and the covering proportion and safe to operate, the construction quality and the impression effect of the thatch-imitated roof are improved to a large extent, and good social benefits, economic benefits and environment-friendly benefits are achieved.

Owner:中铁二十一局集团第二工程有限公司

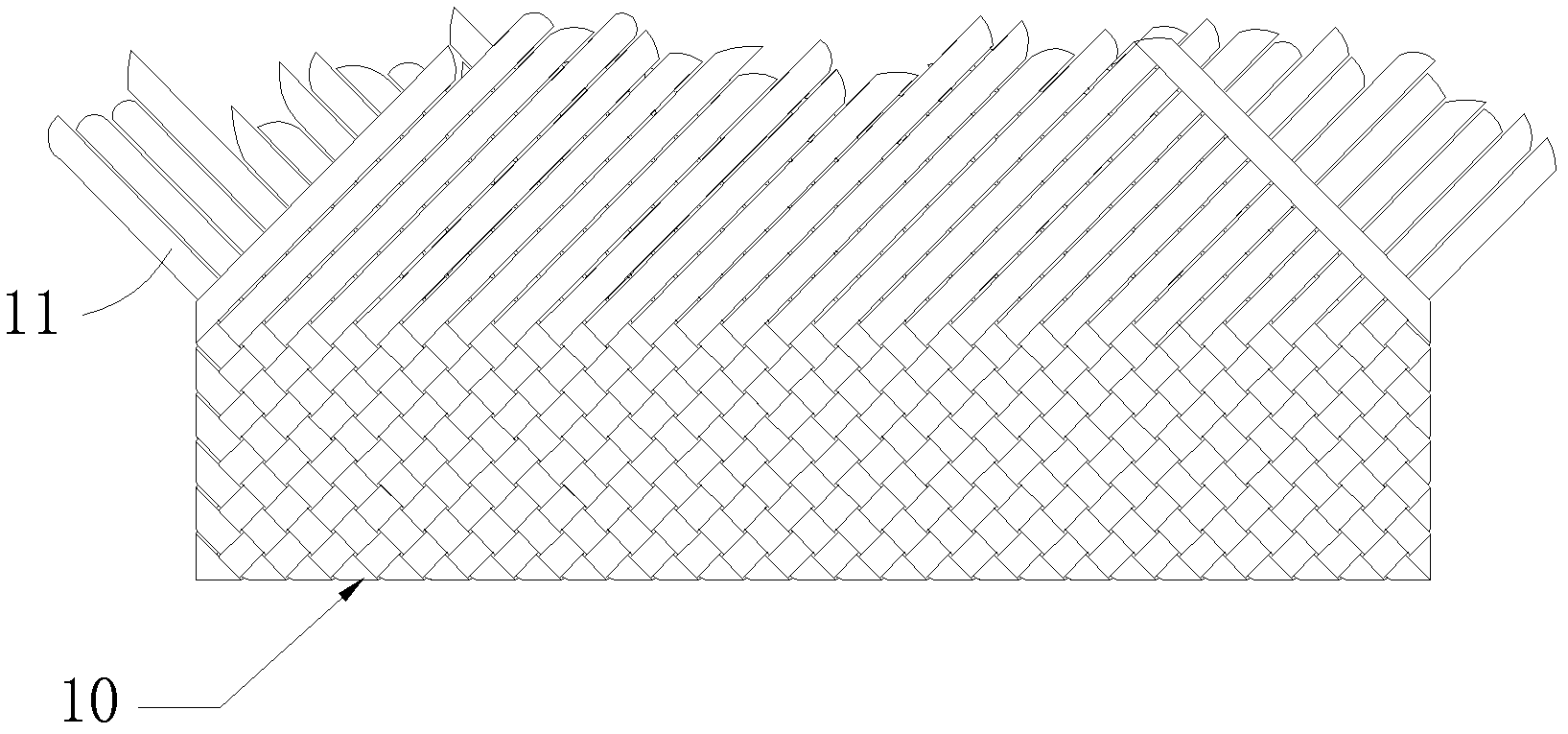

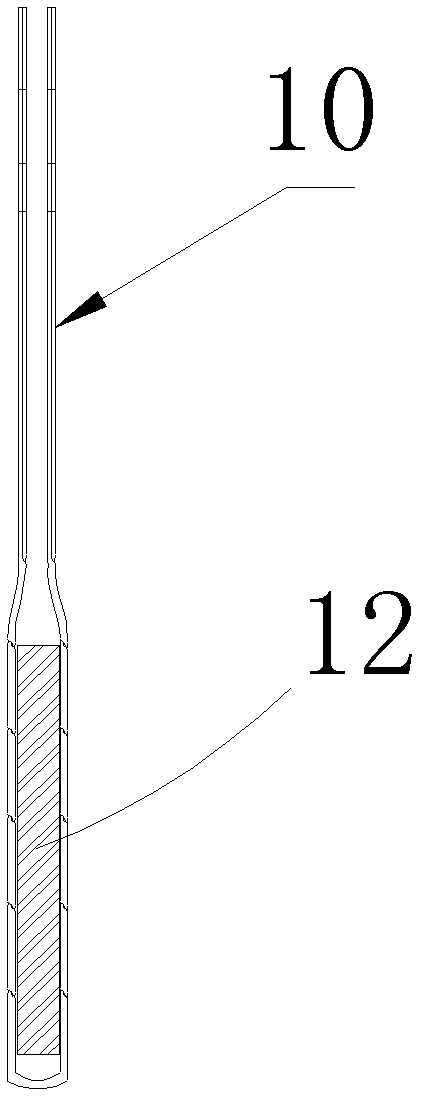

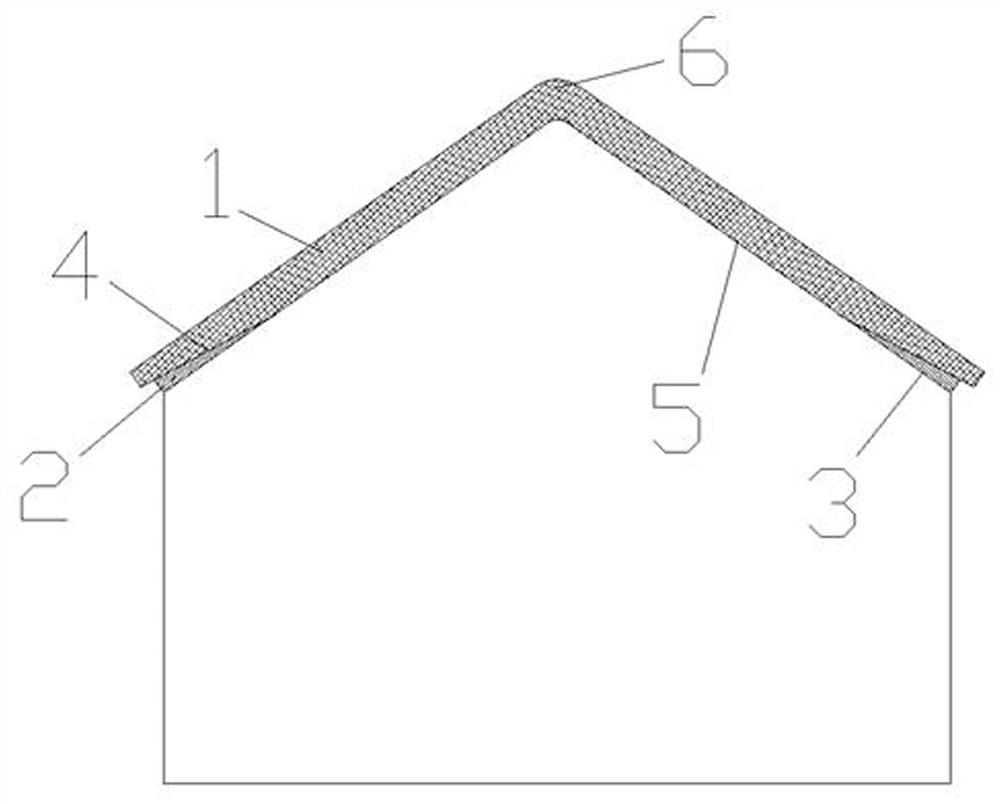

Thatch house roof surface structure and construction method thereof

InactiveCN112392207AEasy to drainConstruction experienceRoof covering using straw/thatchRoof toolsArchitectural engineeringStructural engineering

The invention provides a thatch house roof surface structure and a construction method thereof. The structure comprises a roof structure layer, and the roof structure layer comprises a large edge, a small edge, a yellow mud bottoming layer, a yellow mud connecting layer, a yellow mud layer and a ridge. The yellow mud bottoming layer is laid on the structure layer, the small edge is laid on the yellow mud bottoming layer at the extension position of a roof, the yellow mud connecting layer is laid on the small edge, the large edge is laid on the yellow mud connecting layer in the roof directionin sequence, the yellow mud layer is laid on the large edge again, and a thatch layer is laid on the yellow mud layer finally. According to the structure, the excellent physical properties of thatch materials are utilized, and the construction method that the thatch materials are constructed according to a traditional process is adopted, so that the construction of the thatch house is more experienced, handmade, standardized and industrialized. The thatch materials serve as a roof surface layer, the heat preservation and insulation performance of the thatch materials is utilized, meanwhile, due to the fact that the thatch materials have the anti-corrosion and windproof performance, a decorative material can be exposed, an anti-cracking material and a paint do not need to be additionally arranged for protection, and unification of functionality and decoration is achieved. By means of the mature construction method, the style and feature of a traditional thatch house dwelling are reserved, and the performance and quality of the thatch house are improved.

Owner:李达

Plastics fibre housetop and manufacturing method therefor

InactiveCN100567673CNo pollutionBuilding roofsRoof covering using straw/thatchPlant fibreEngineering

Owner:YUZHOU CITY LVZHIZHOU GARDEN APPLIANCE MFG

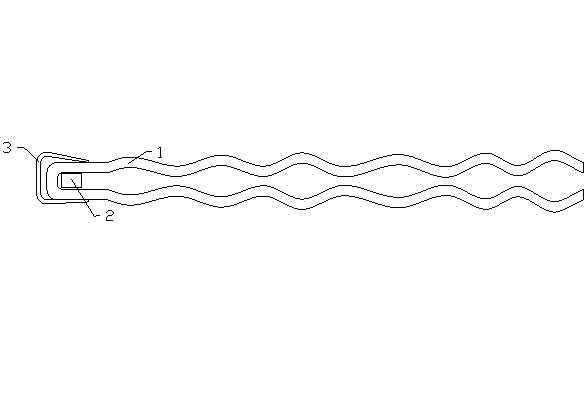

Manufacturing method of waterproof thatch

PendingCN112917933ASolve the leakExtended service lifeCovering/liningsMaterial gluingWater leakageProcess engineering

The invention discloses a manufacturing method of waterproof thatch. The manufacturing method comprises the following steps that 1, multiple trays of thatch are placed on a warp beam of a machine through a tray, then a machine is started, the warp beam rotates, mechanical extrusion is automatically carried out, and the middle of the extruded thatch is fixed through hot melting by a hot melt adhesive after the extrusion is finished, so that the waterproof thatch is manufactured. The length of the waterproof thatch can be cut at will, and the width of the waterproof thatch can be lengthened or shortened according to actual requirements of customers. According to the manufacturing method, an integrated production technology is adopted, the product length can be cut at will in the production process, hot melting can be conducted, the prepared waterproof thatch can solve the problem of water leakage, the service life of the product is prolonged, and the attractiveness of the product is improved.

Owner:邓均兴

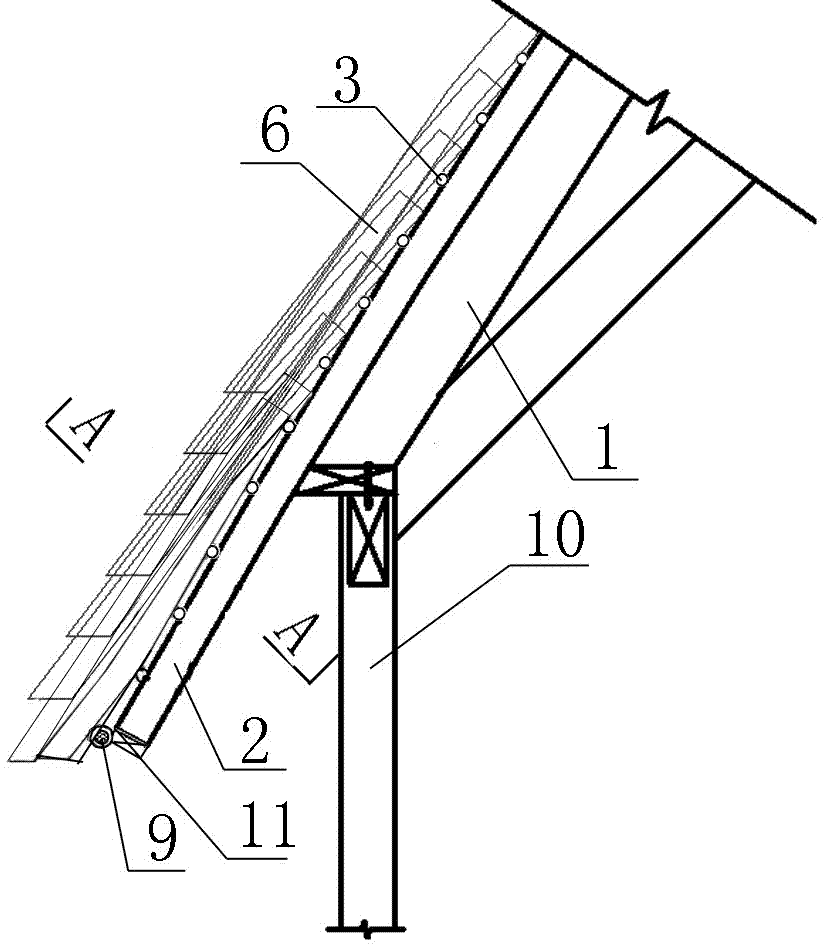

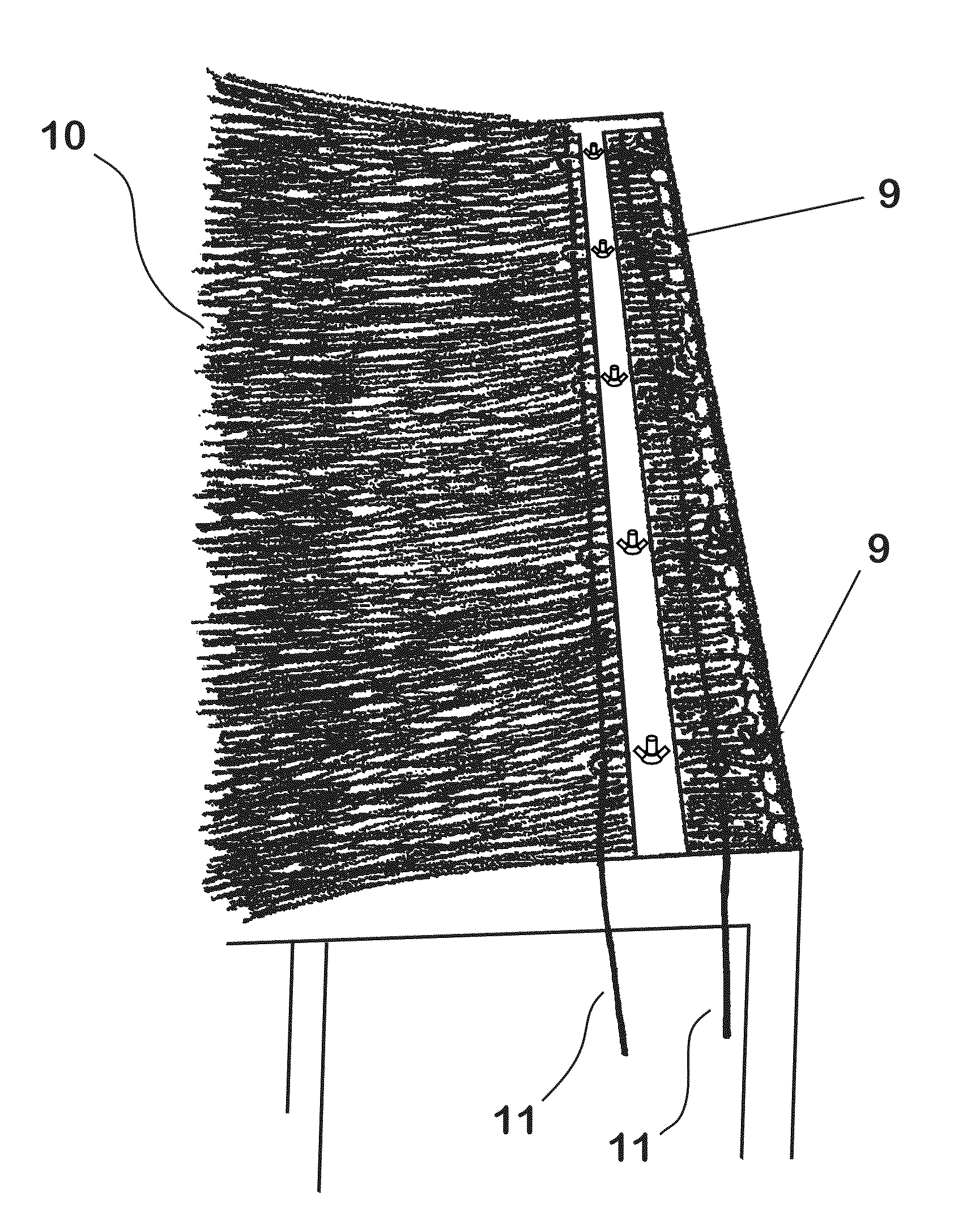

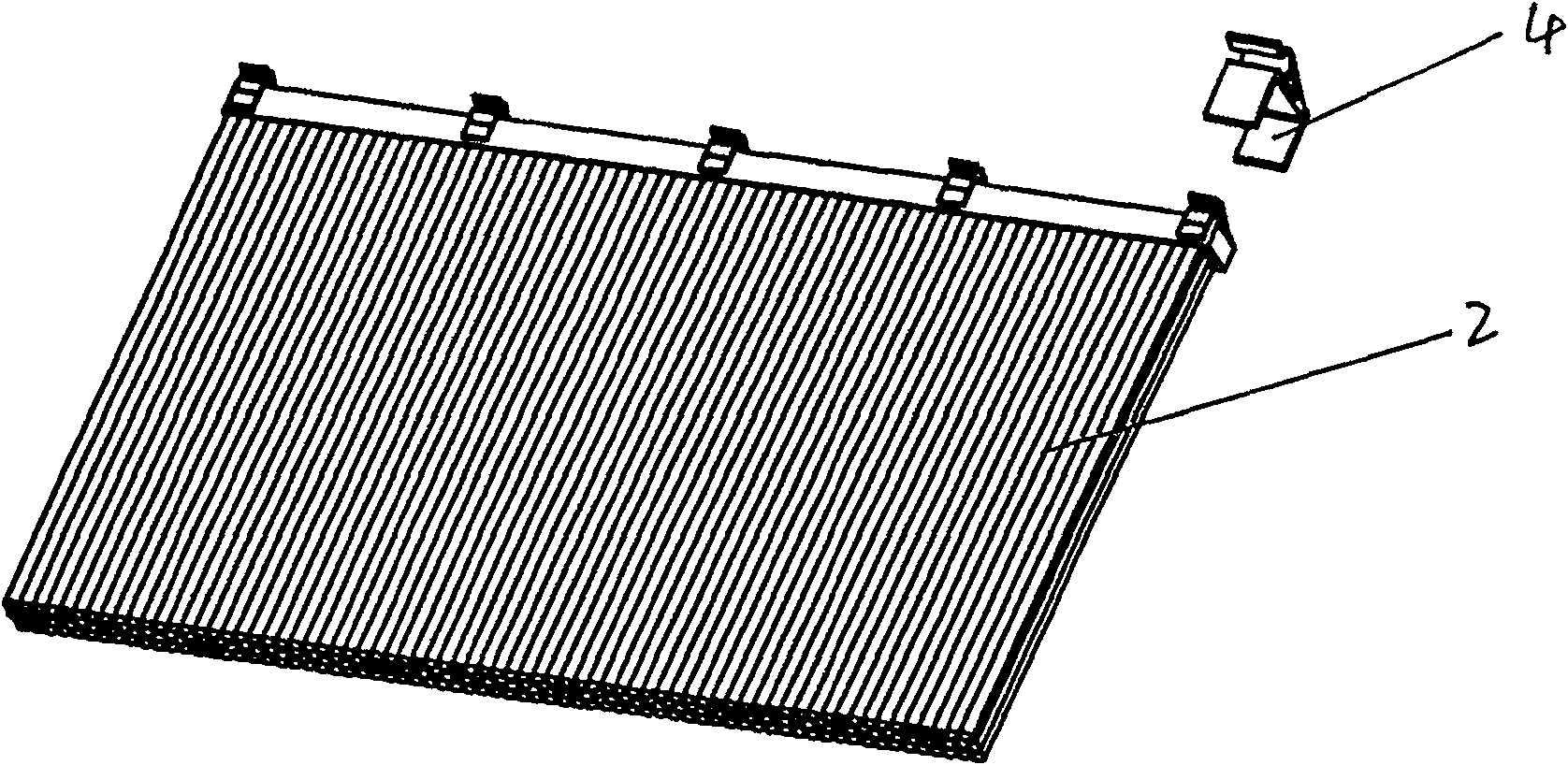

Laying process of natural reed grass roof

PendingCN112240081AImprove visual effectsRoof covering using straw/thatchAgricultural scienceAgricultural engineering

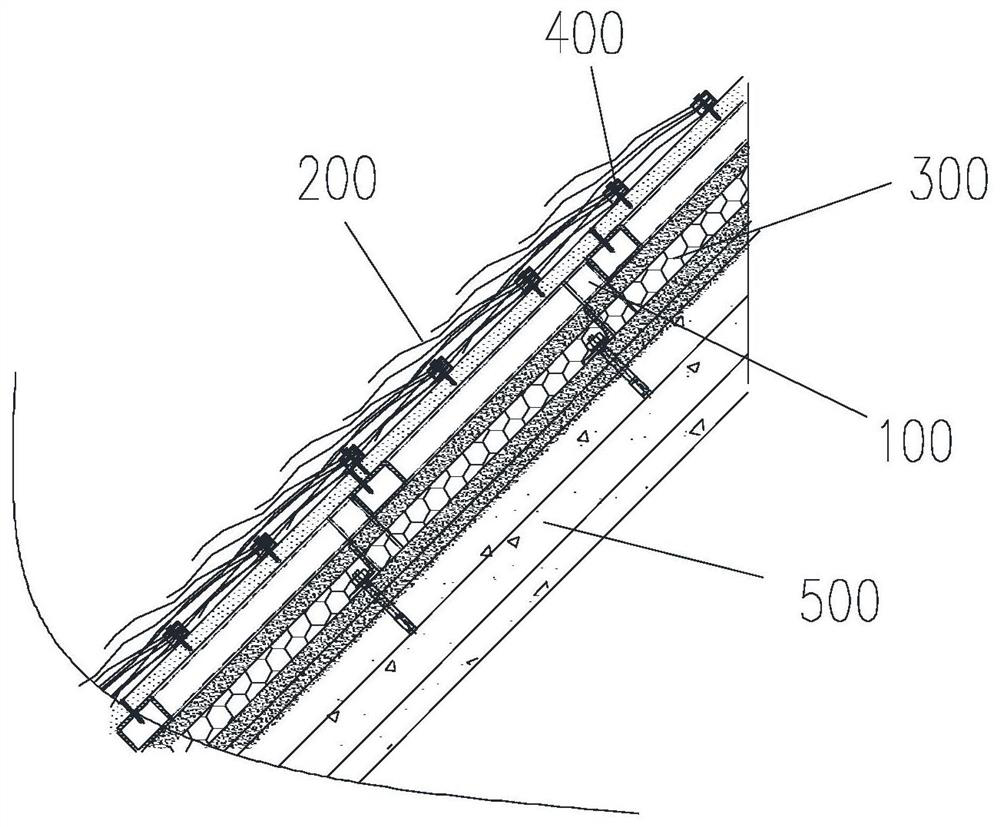

The invention discloses a laying process of a natural reed grass roof. The laying process comprises the following steps of laying keel components, fixing bandages on transverse keels, and laying on the keel components layer by layer from eaves to a ridge. When the reed grass on the lowermost layer is laid, firstly, the reed grass is laid on the transverse keels, the fixing strips placed outside the reed grass are primarily fixed through step-by-step fasteners, the reed grass on the layer is primarily trimmed layer by layer through grass trimming plates, the fixing strips are fixed through thebandages to finish final fixing, and the step-by-step fasteners are removed. The upper layer of reed grass is laid by referring to the process, and the fixing strips of the next layer of reed grass are covered when the upper layer of reed grass is laid. Closing-in decoration is conducted on the ridge through external materials, and final-level trimming is conducted through the grass trimming plates. Natural reed grass is recycled for laying, energy conservation and environmental protection are achieved, the process of folk originals is inherited, part of labor employment is driven, the construction period can be shortened, and the problems that a traditional grass roof is unsafe, high in water absorption rate, prone to decay, collapse and falling, poor in wind resistance, short in servicelife and the like are solved.

Owner:苏州侪联景观工程有限公司

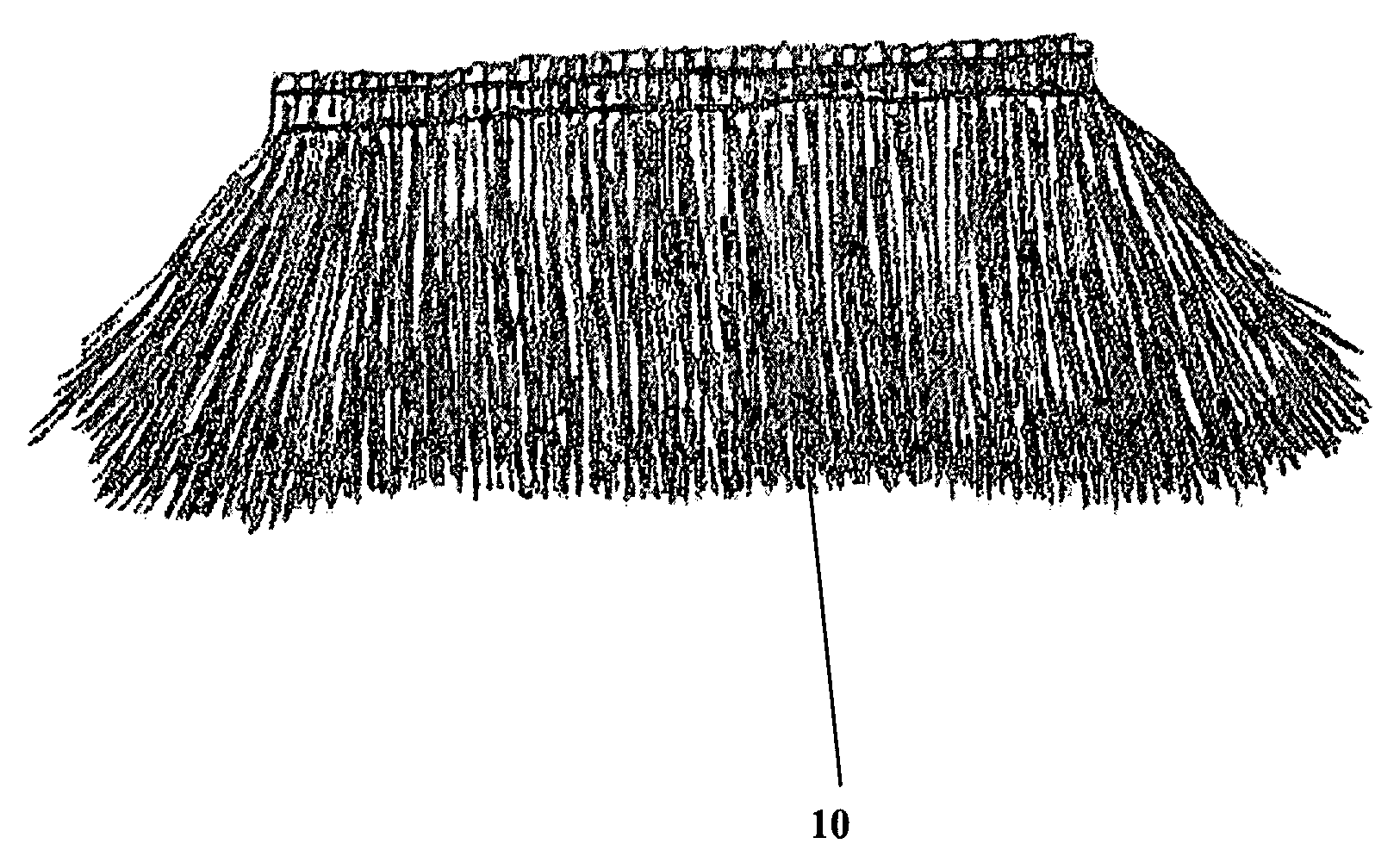

Procedure to manufacture palm roof tiles for rustic roofs and the obtained product

InactiveUS20080047216A1Prevent shrinkageFaster and expeditious systemRoof covering using tiles/slatesRoof covering using straw/thatchRoof tileEngineering

Provided herein are compositions for palm tile, which consists of an assembly of leaves of the palm tree Brahea dulcis, previously torn, placed in a uniformly and symmetrically way and lengthwise sown, stapled or held to the part where the petiole meets the lamina to form a tile, board, panel or Hawaiian skirt. Also provided herein are methods to manufacture the tiles and elements for its elaboration and placement on crosspieces of a structure.

Owner:GARCIA AZCUE ARMANDO CARLOS

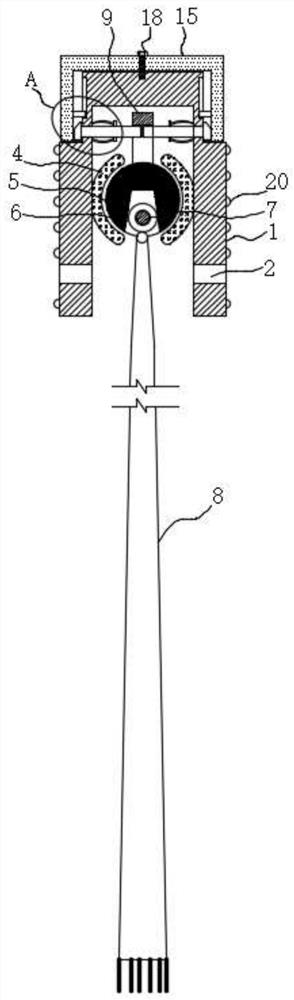

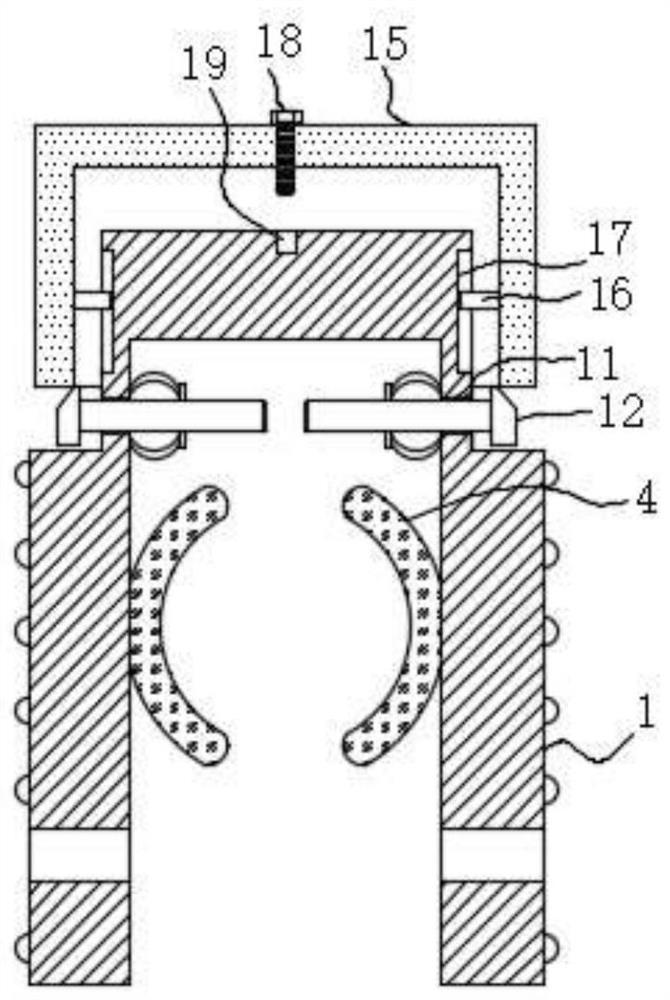

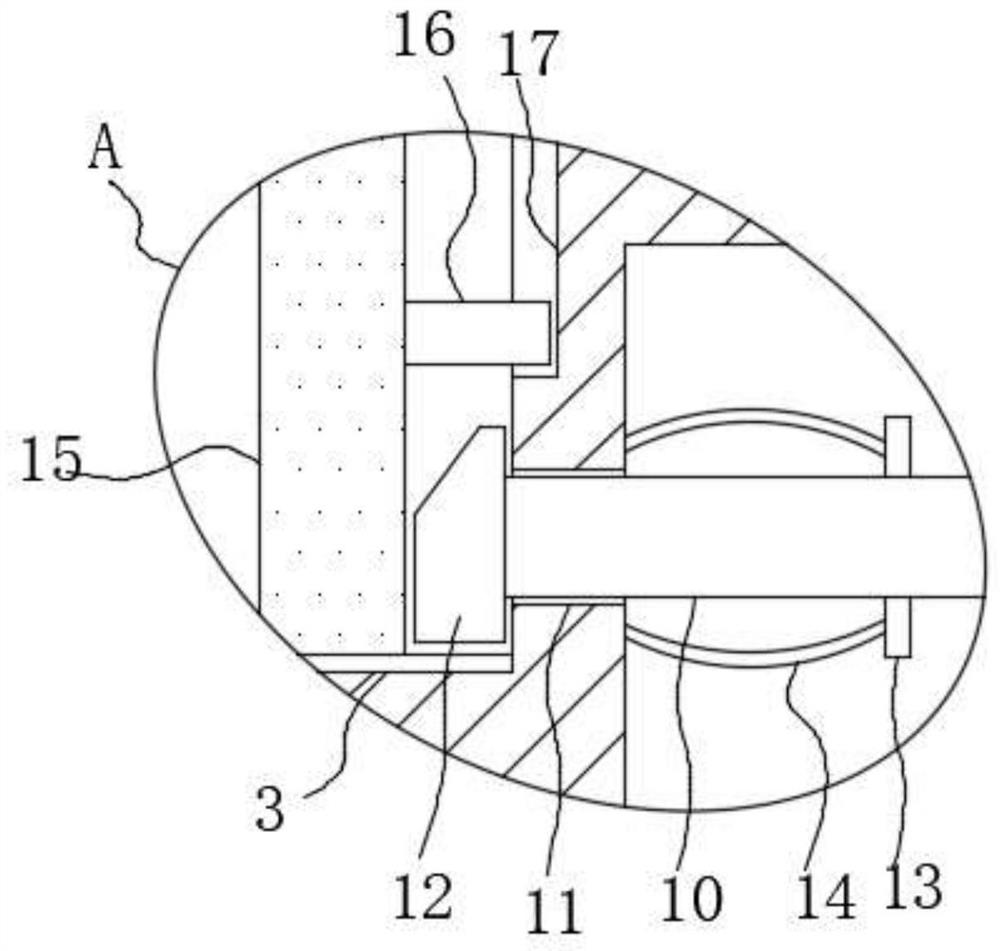

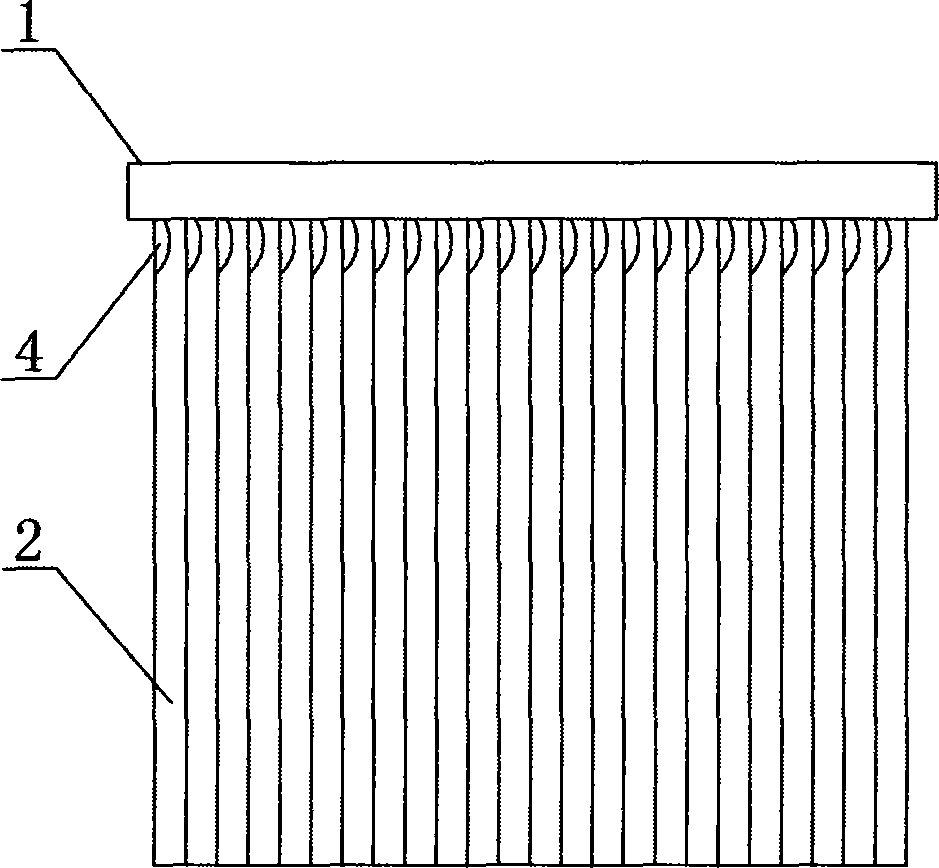

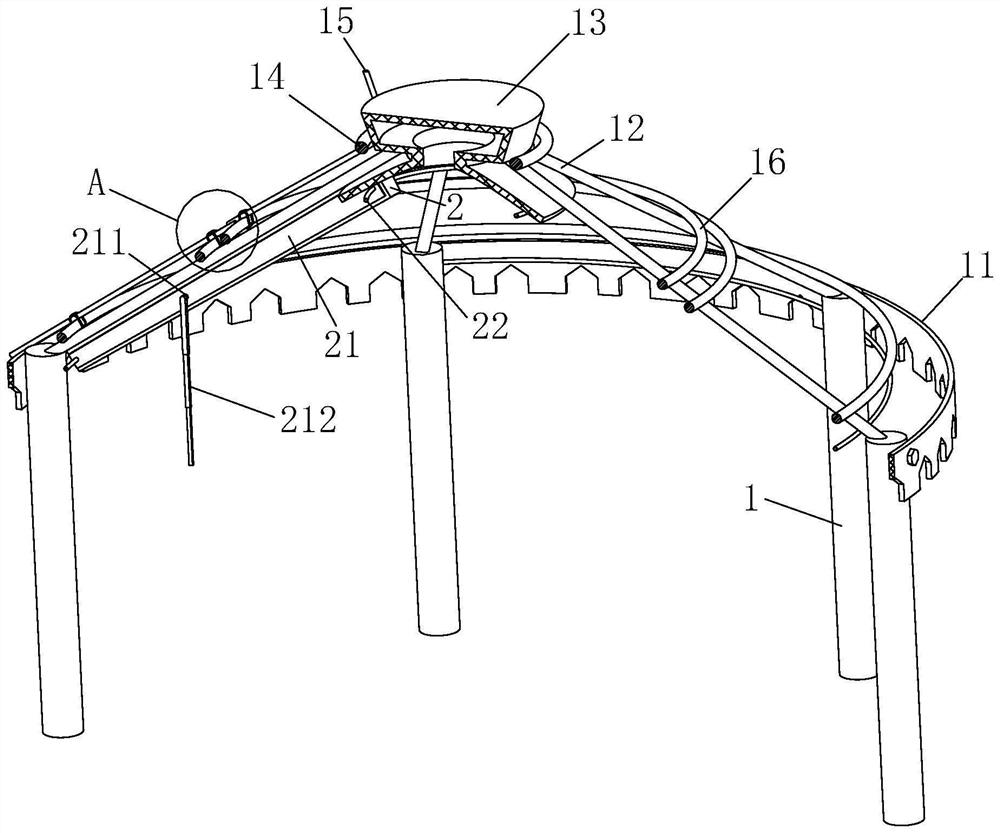

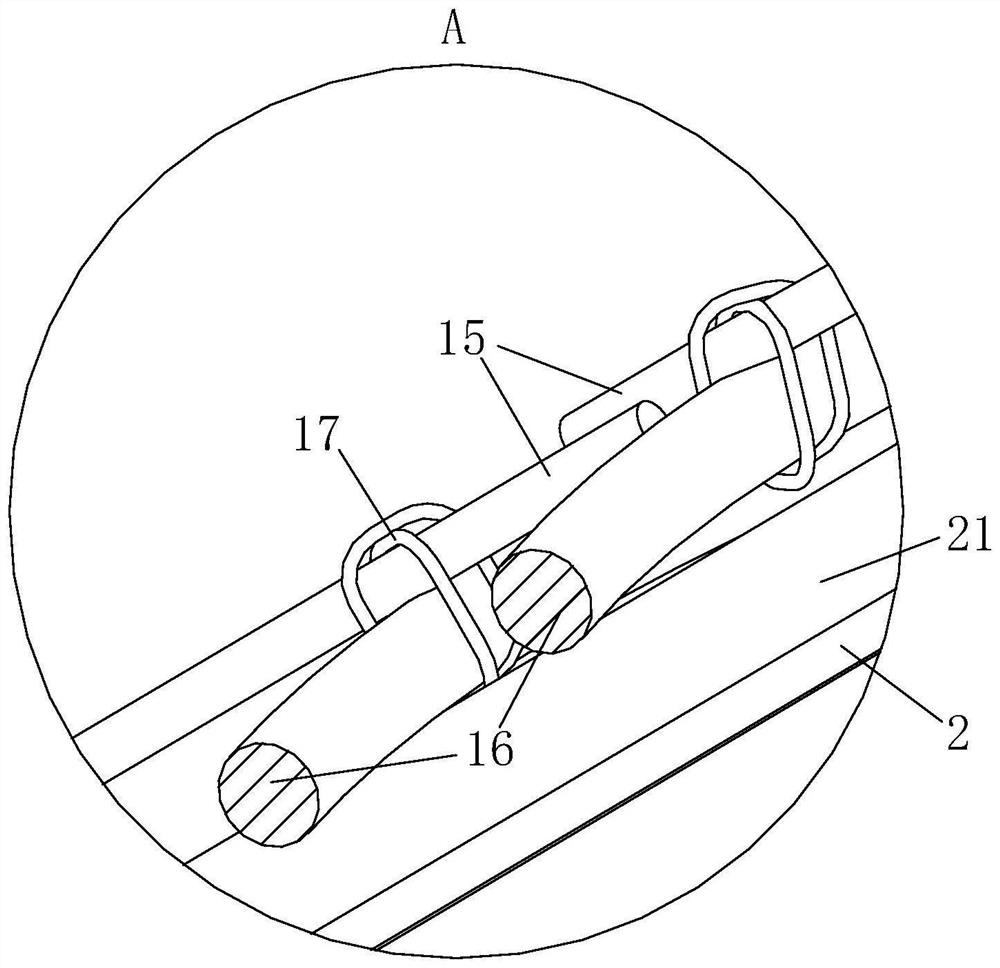

Prefabricated spliced thatch-like roof structure

ActiveCN113738028ARealize individual replacementEasy to operateRoof covering using straw/thatchClassical mechanicsEngineering

The invention relates to the technical field of thatch-like roof splicing assemblies, in particular to a prefabricated spliced thatch-like roof structure. The prefabricated spliced thatch-like roof structure comprises a mounting steel frame, a clamping mounting piece and a hoisting limiting piece, wherein reserved fixing holes are formed in side plates of the mounting steel frame, and edge grooves are formed in the top face of the mounting steel frame; the clamping mounting piece is arranged inside the mounting steel frame, and a simulation thatch bundle is arranged at the bottom of the clamping mounting piece; and the hoisting limiting piece is arranged on the surfaces of the edge grooves, and the top of the mounting steel frame is provided with a protection piece in a sleeved mode to limit the hoisting limiting piece. The prefabricated spliced thatch-like roof structure has the beneficial effects that the simulation thatch bundle is connected to a cross rod in a bolted mode, when the simulation thatch bundle is replaced, a locking screw rod is loosened, a buckle plate is pulled upwards, in this way, a limiting rod is pulled by a rebounded metal elastic sheet to extend outwards, then a hanging ring is not limited by the limiting rod any more, the simulation thatch bundle is pulled to be pulled out of the position between two elastic limiting seats, then the simulation thatch bundle is replaced, the operation is simple and convenient, and the independent replacement of the simulation thatch bundle is realized.

Owner:SHANDONG YINGCAI UNIV

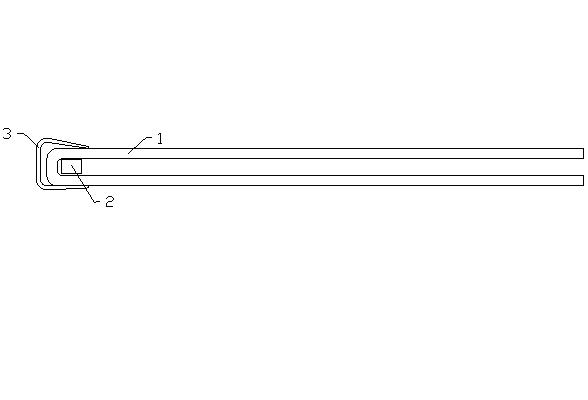

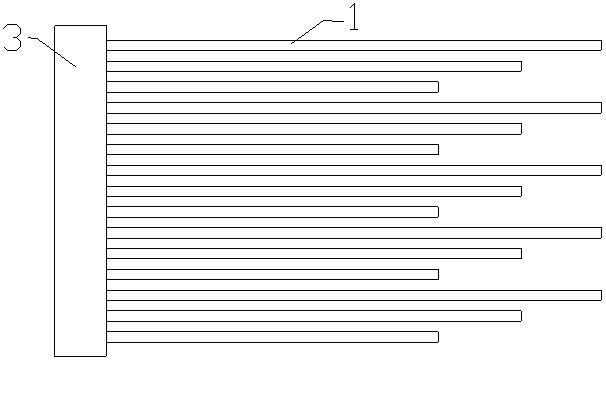

Landscape house roof bamboo hat block and production method thereof

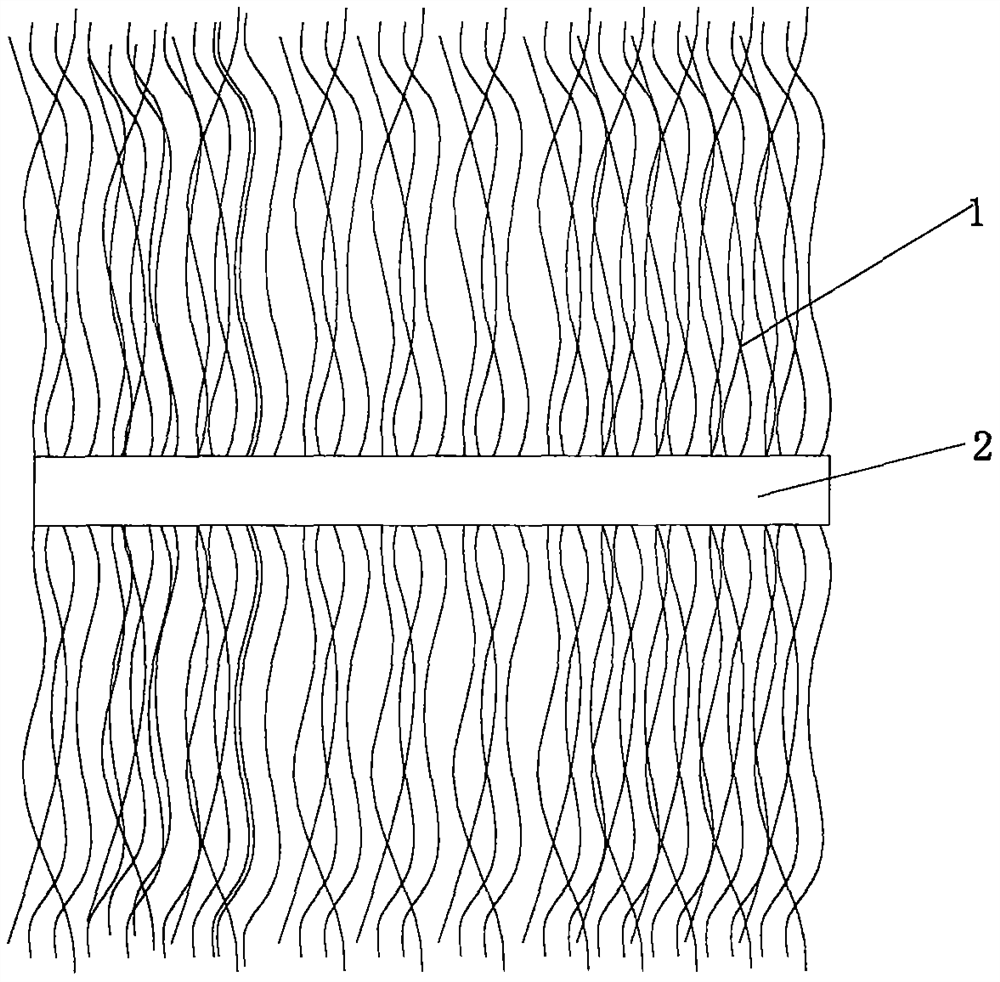

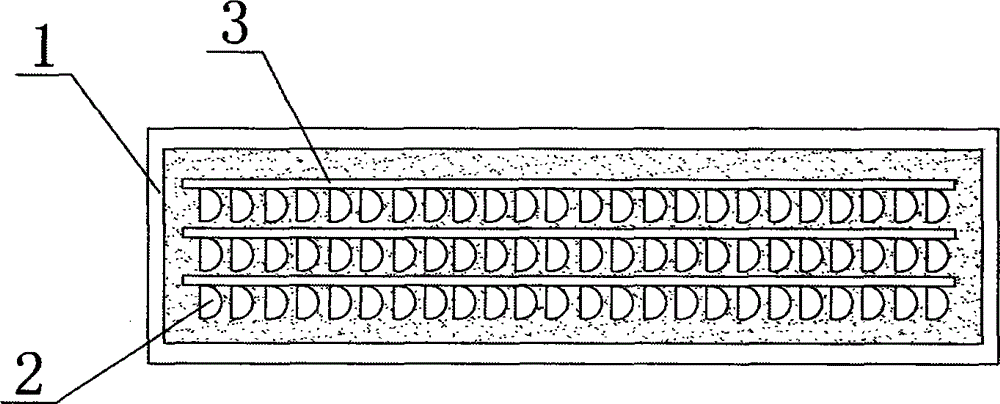

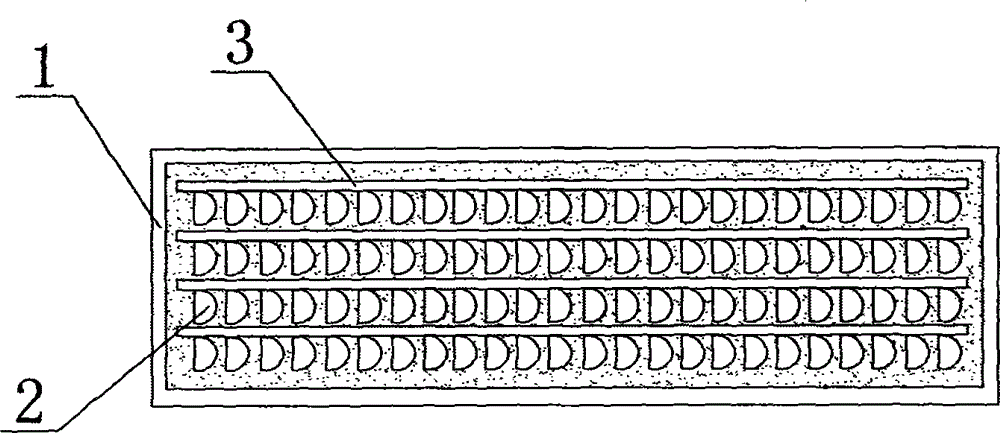

InactiveCN104563401APrevent rotEasy to organizeRoof covering using straw/thatchWater leakageFixed frame

The invention relates to a decorative material for landscape house roofs, in particular to a landscape house roof bamboo hat block and a production method thereof. The landscape house roof bamboo hat block comprises an artificial plastic strip assembly and a fixing frame clamped to the root of one end of the artificial plastic strip assembly, the artificial plastic strip assembly comprises a group of laminated plastic strip layers, each plastic strip layer comprises a plurality of plastic strips and an adhesive tape arranged at one ends of the plastic strips, the plastic strips on each plastic strip layer are parallelly arrayed and tightly disposed, two ends of each plastic strip are kept aligned, each adhesive tape is attached to the side edge of one ends of the arrayed plastic strips and is adhered to each plastic strip of one plastic strip layer, the space between one end, clamped by the fixing frame, of the artificial plastic strip assembly and the fixing frame as well as the space among the plastic strip layers at the end of the artificial plastic strip assembly are filled with viscose. The landscape house roof bamboo hat block has the advantages of simplicity in production, use and installation, long decoration duration, difficulty in water leakage and low using cost.

Owner:JIYUAN JINCHENG TECH

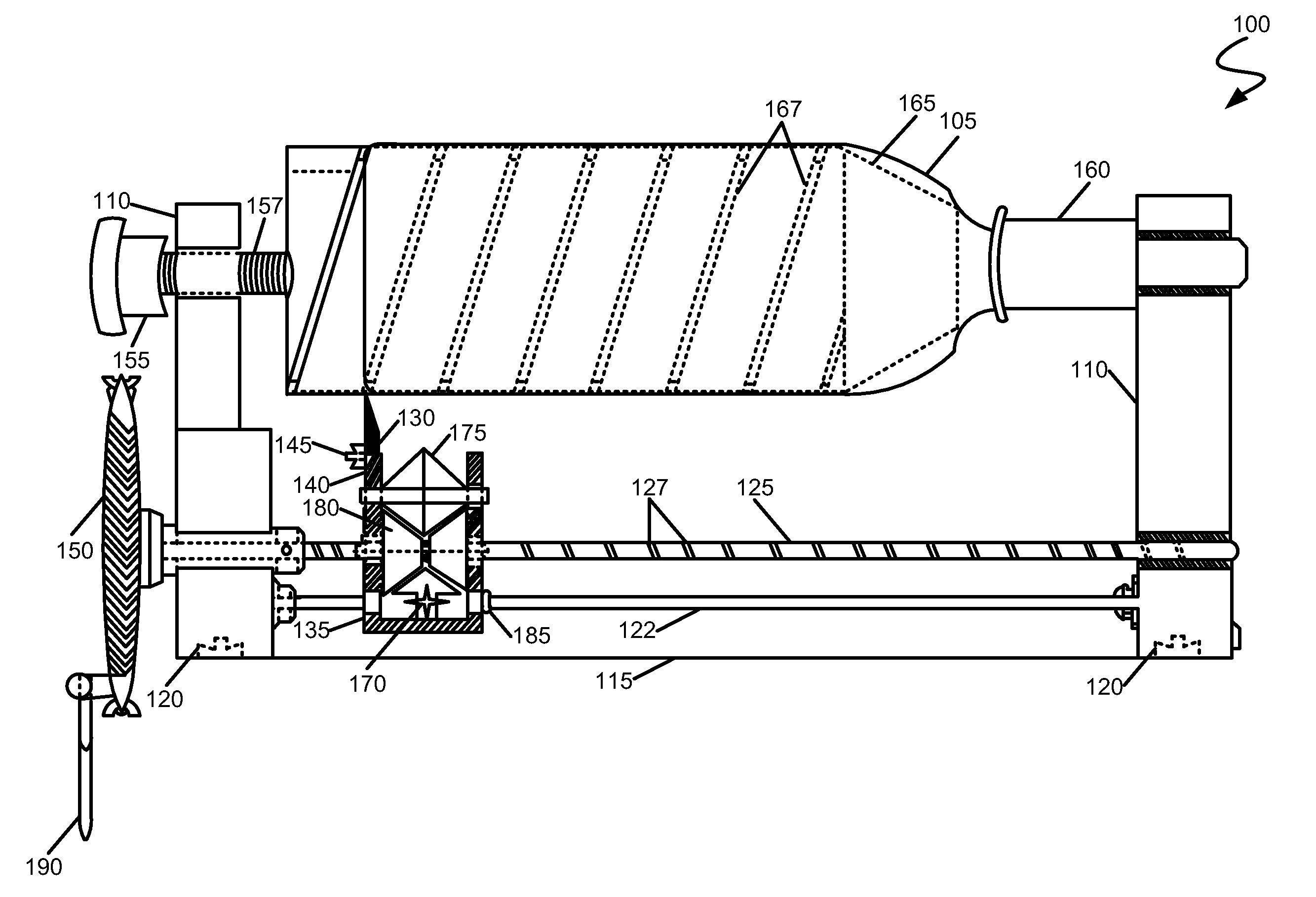

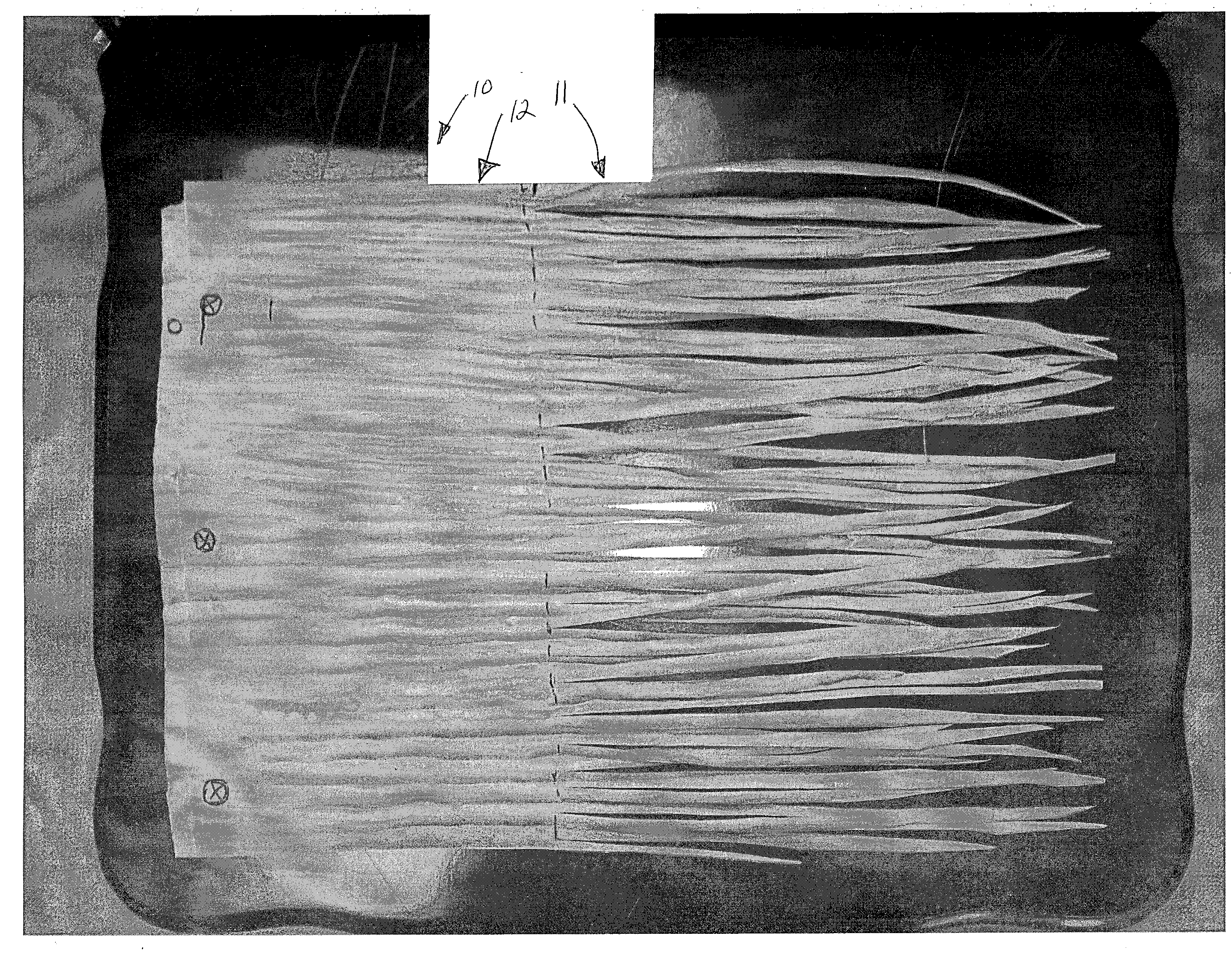

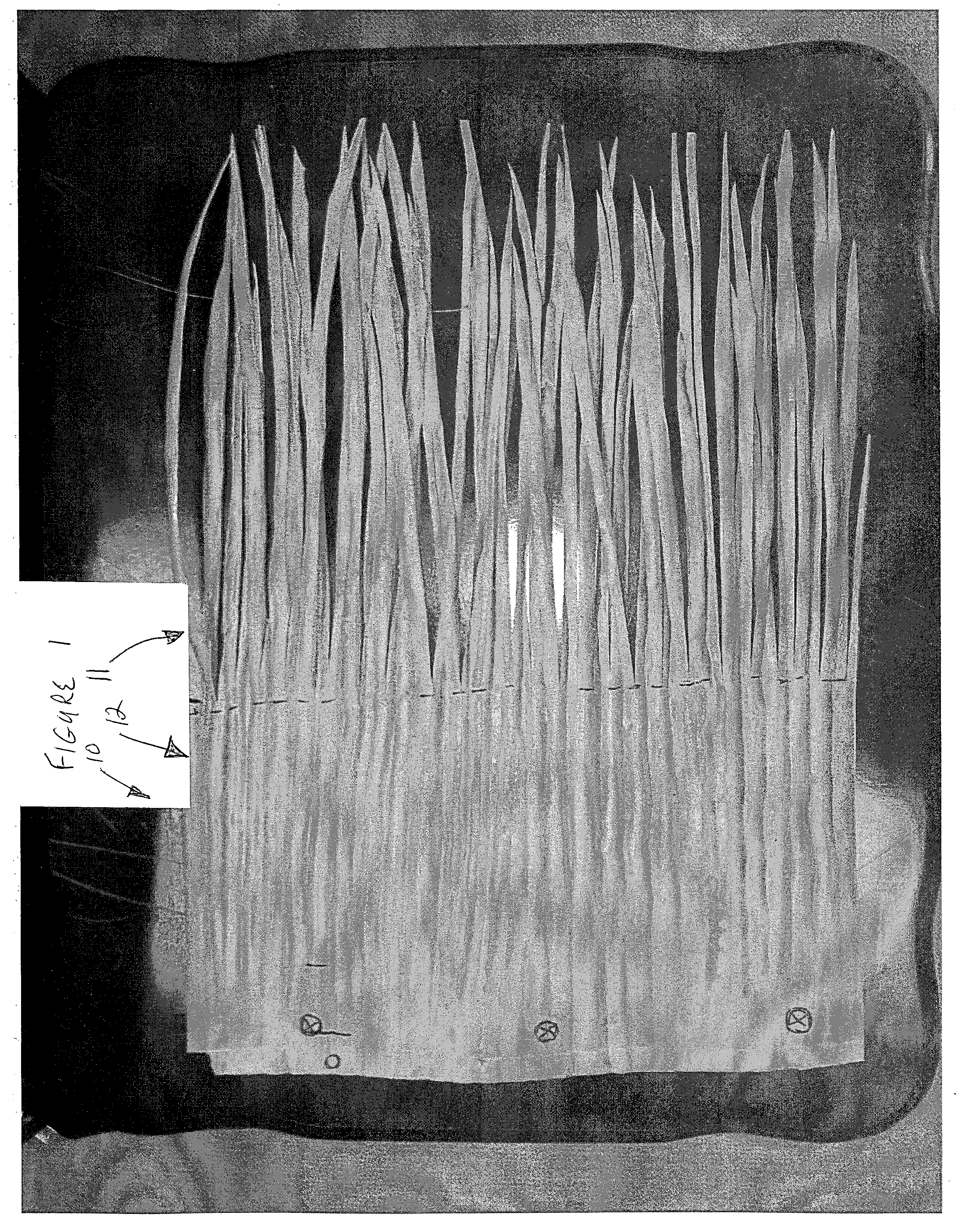

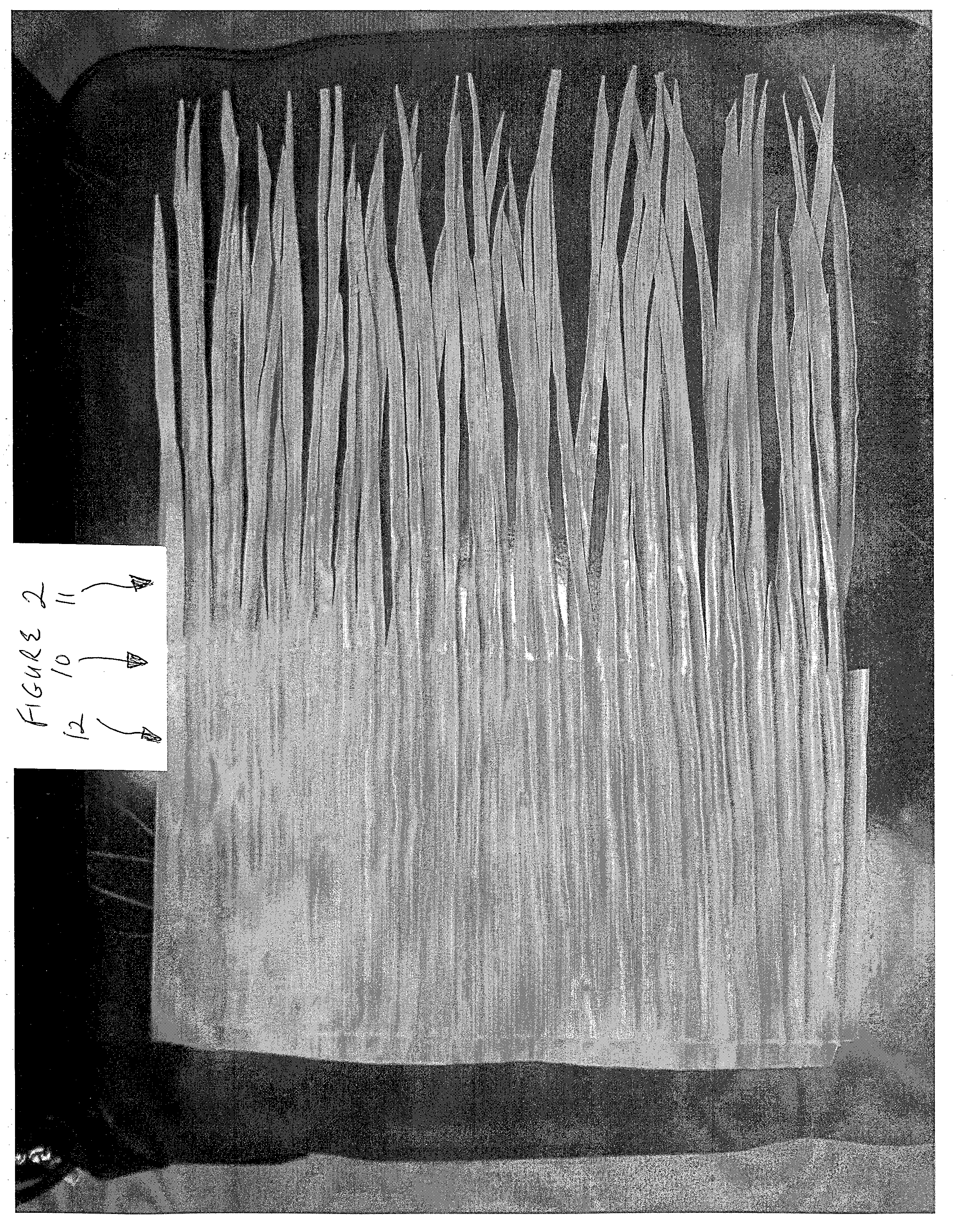

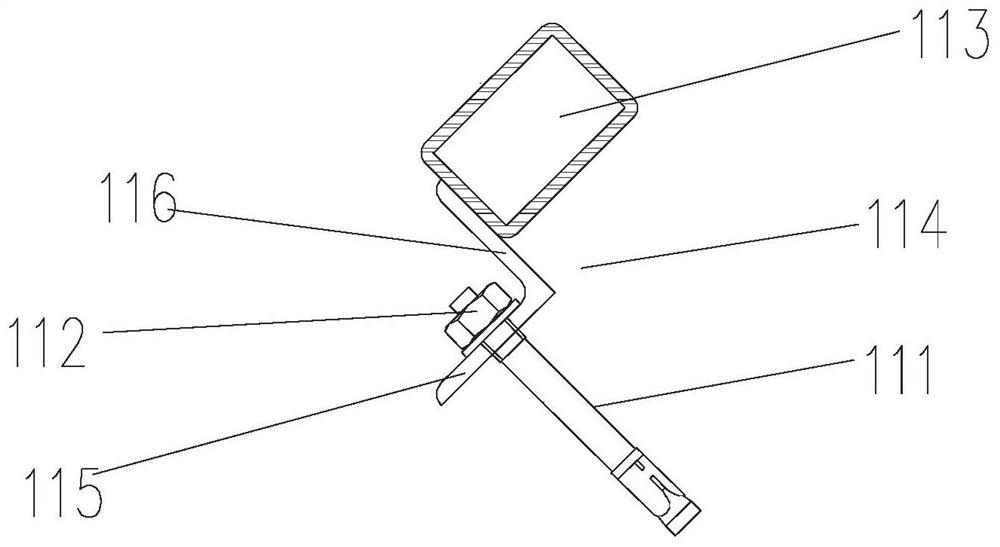

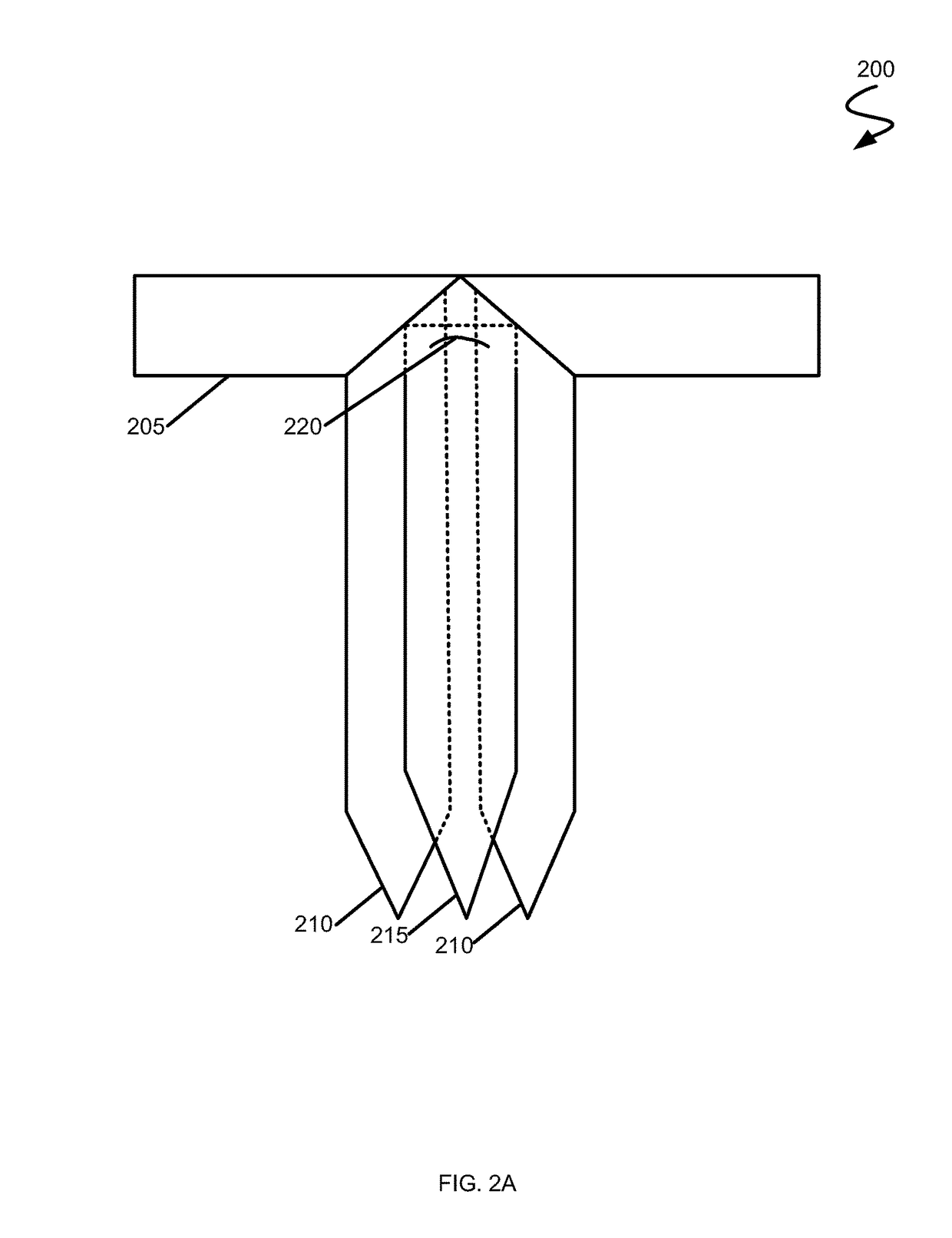

Apparatus and method for producing a thatch roofing material for building construction

To produce a thatch roofing material from waste plastic bottles, an apparatus includes a device for cutting the bottles into one or more strips. The device may include a decontouring unit that removes contours from the bottles and a heated clamp that fuses the strips together lengthwise to create a plastic tape. A bottle may be formed into rectangular stock by removing the top and bottom and longitudinally cutting the middle part. The rectangular stock may be cut into the cut strips, such as with a wire cutter. The plastic tape may be used to create folded thatch components by cutting, from the plastic tape, one or more slats and one or more thatch roofing material strips, and folding and attaching the thatching roofing material strips to the slats. Serrated ties may be cut from the plastic tape and used to fasten the folded thatch components to a building structure.

Owner:SAIIA DAVID

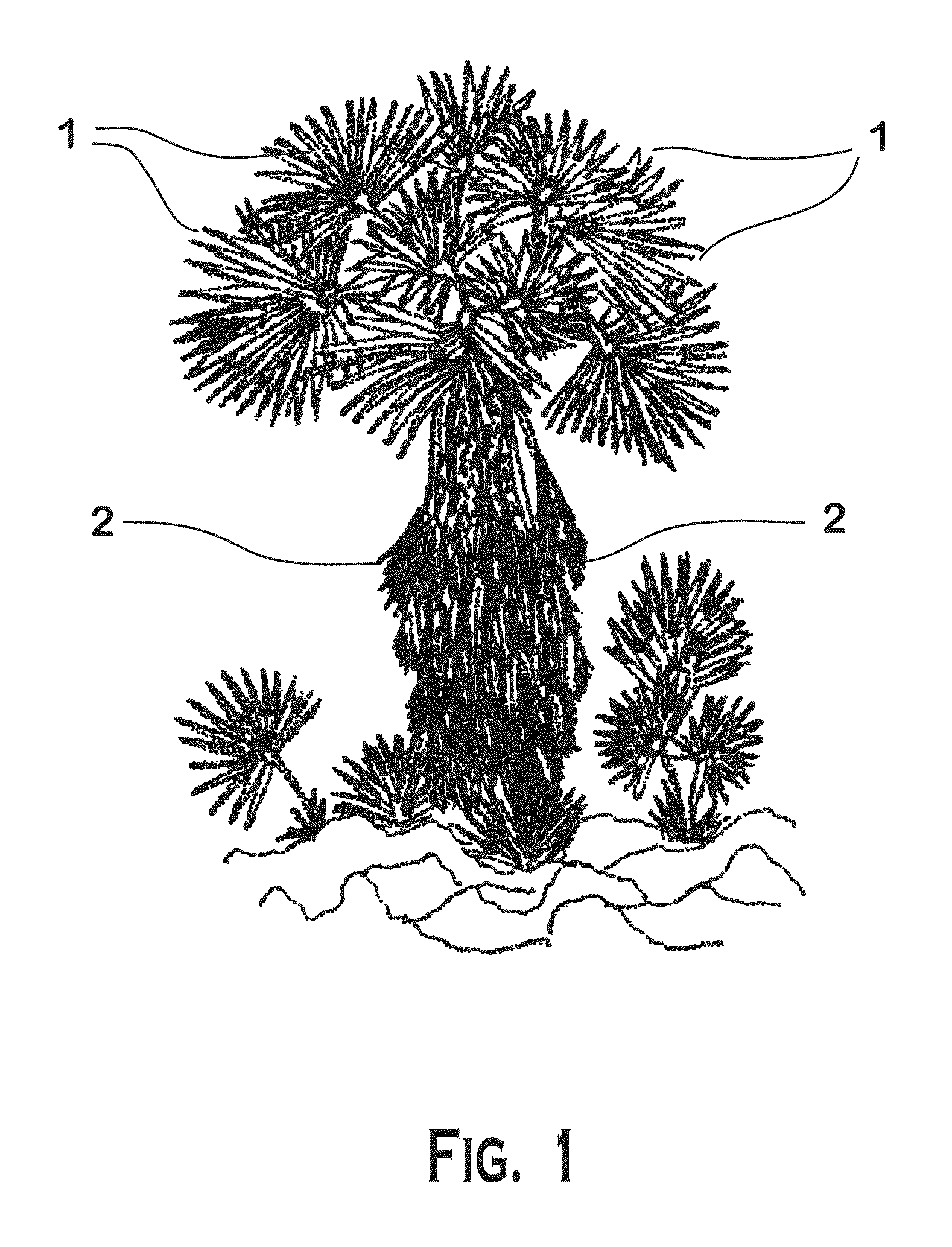

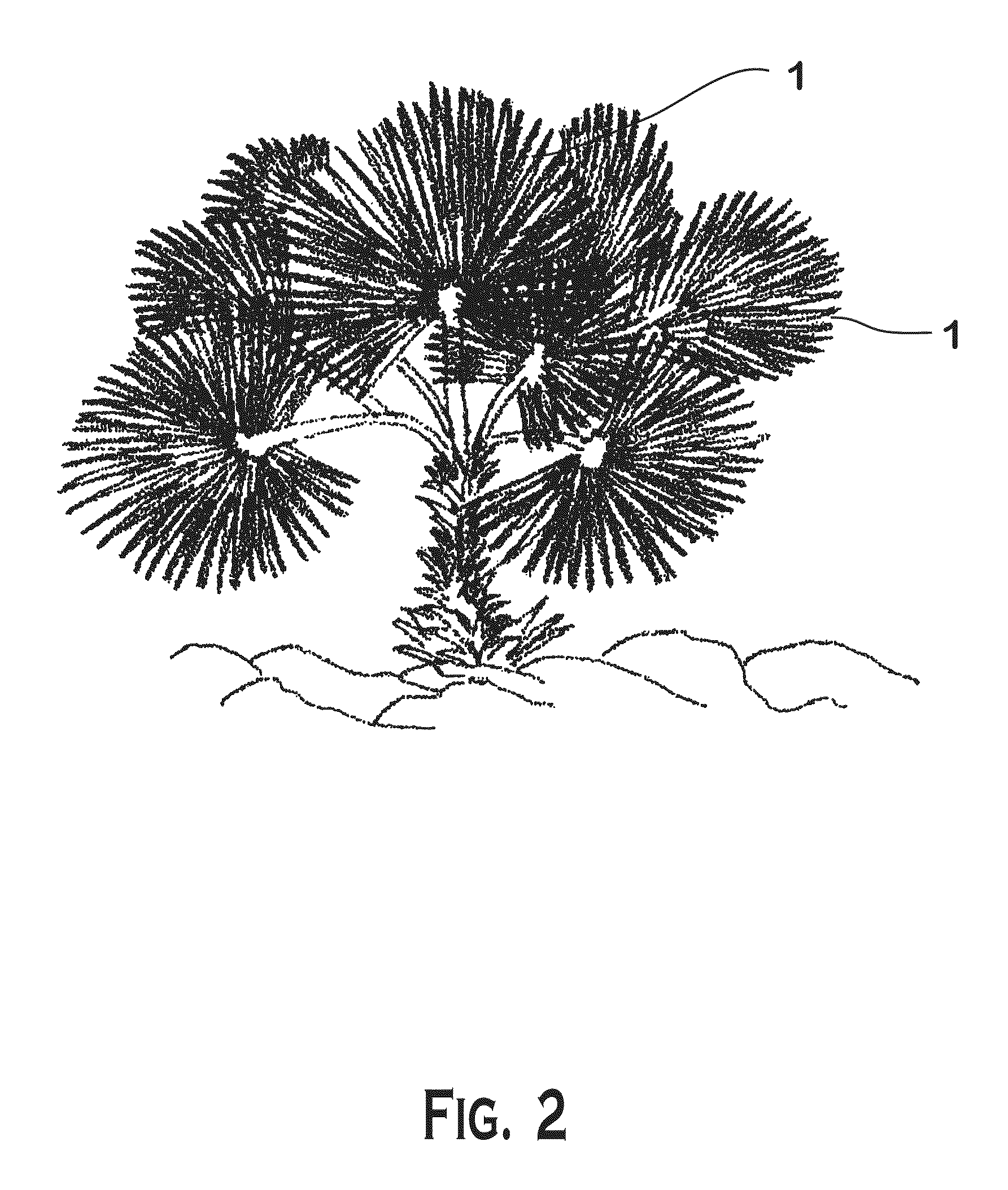

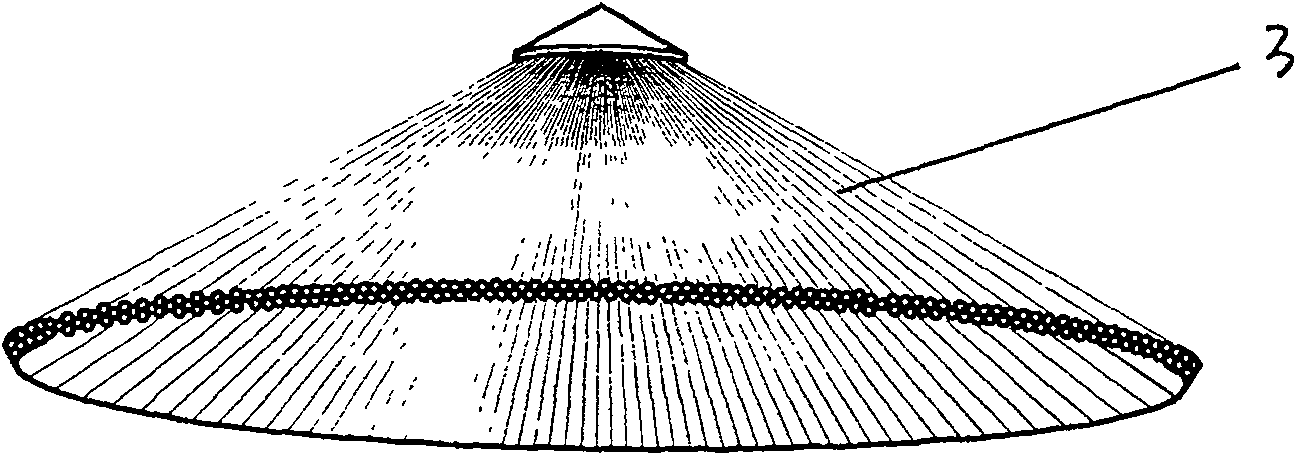

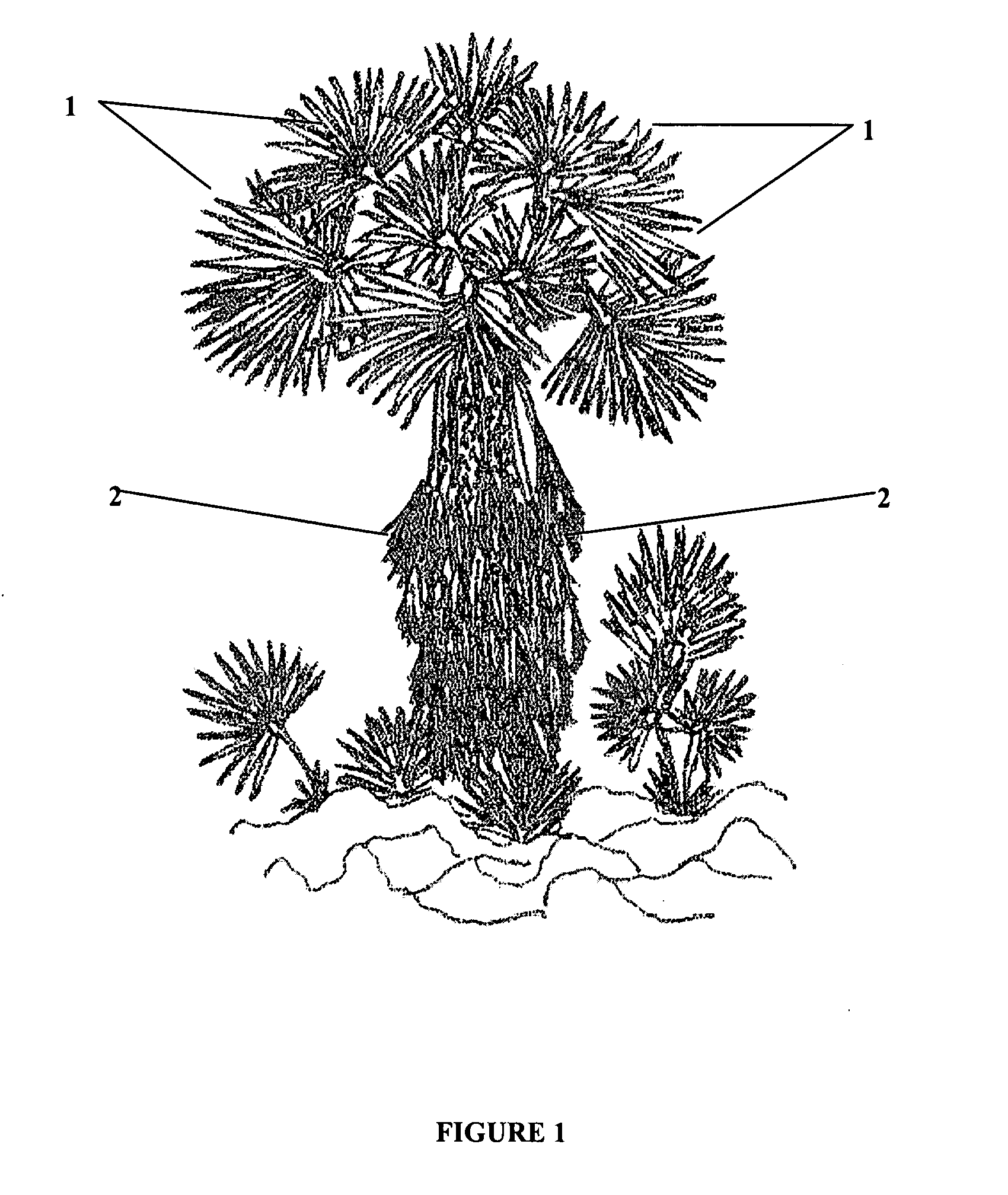

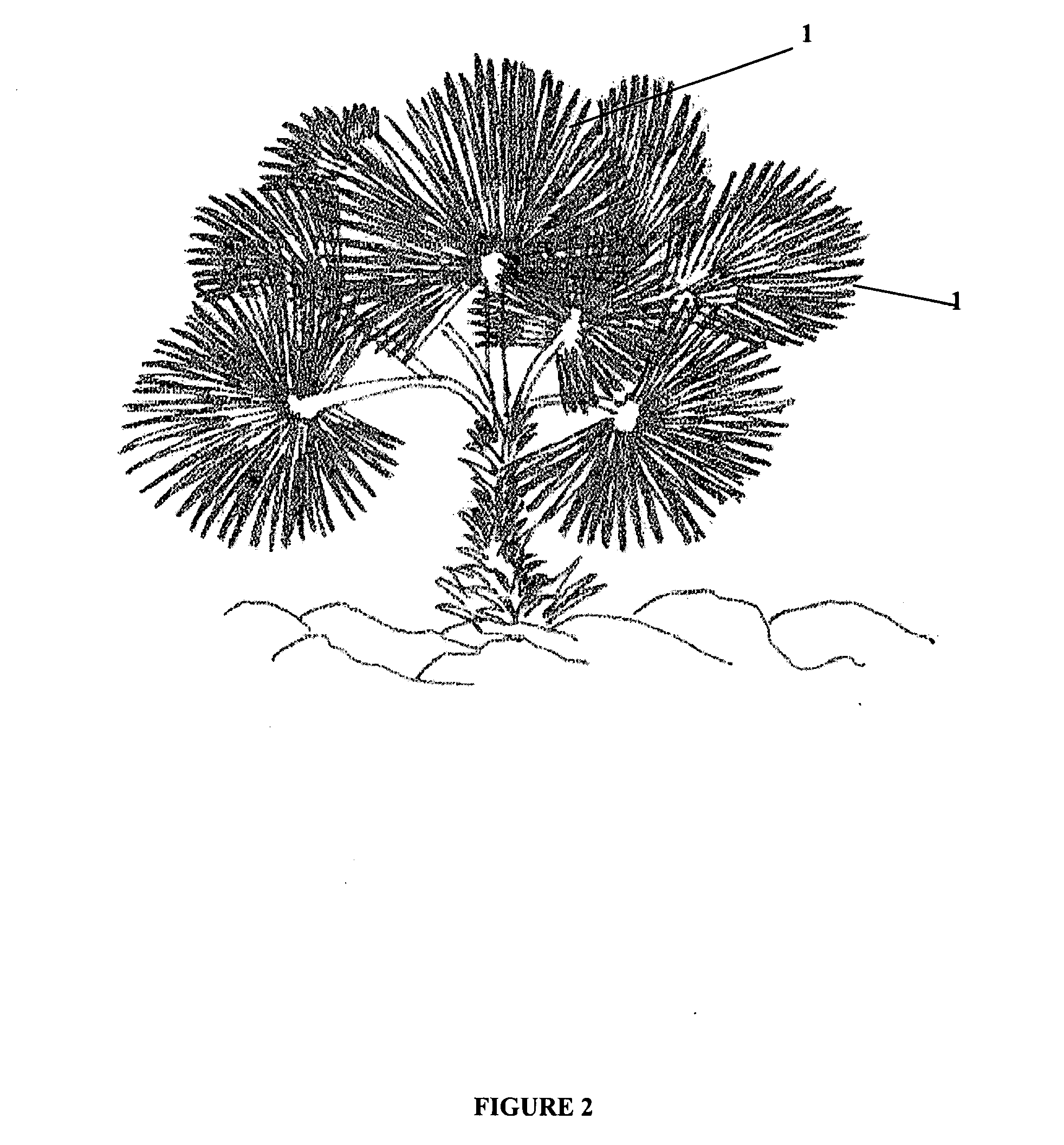

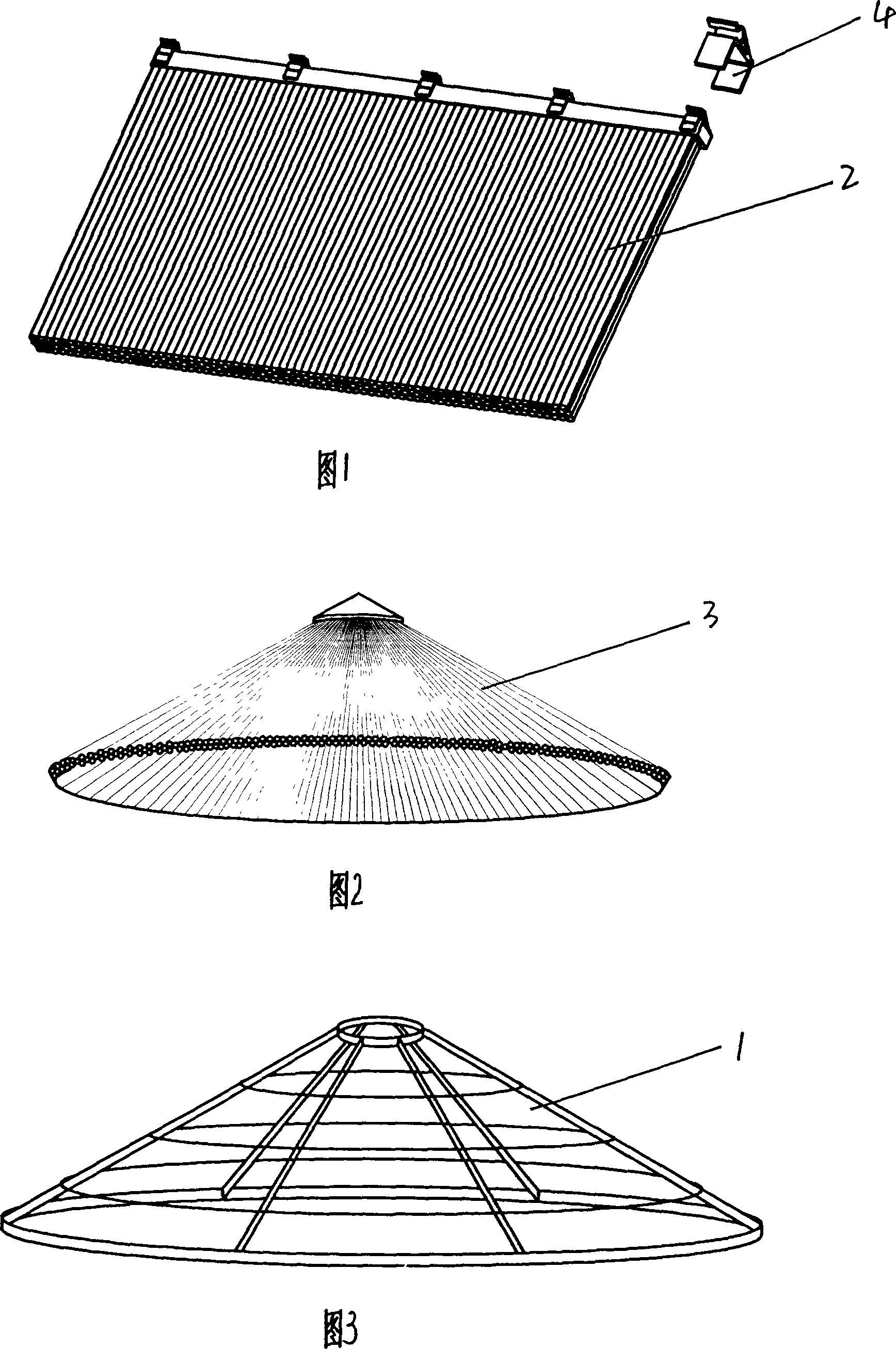

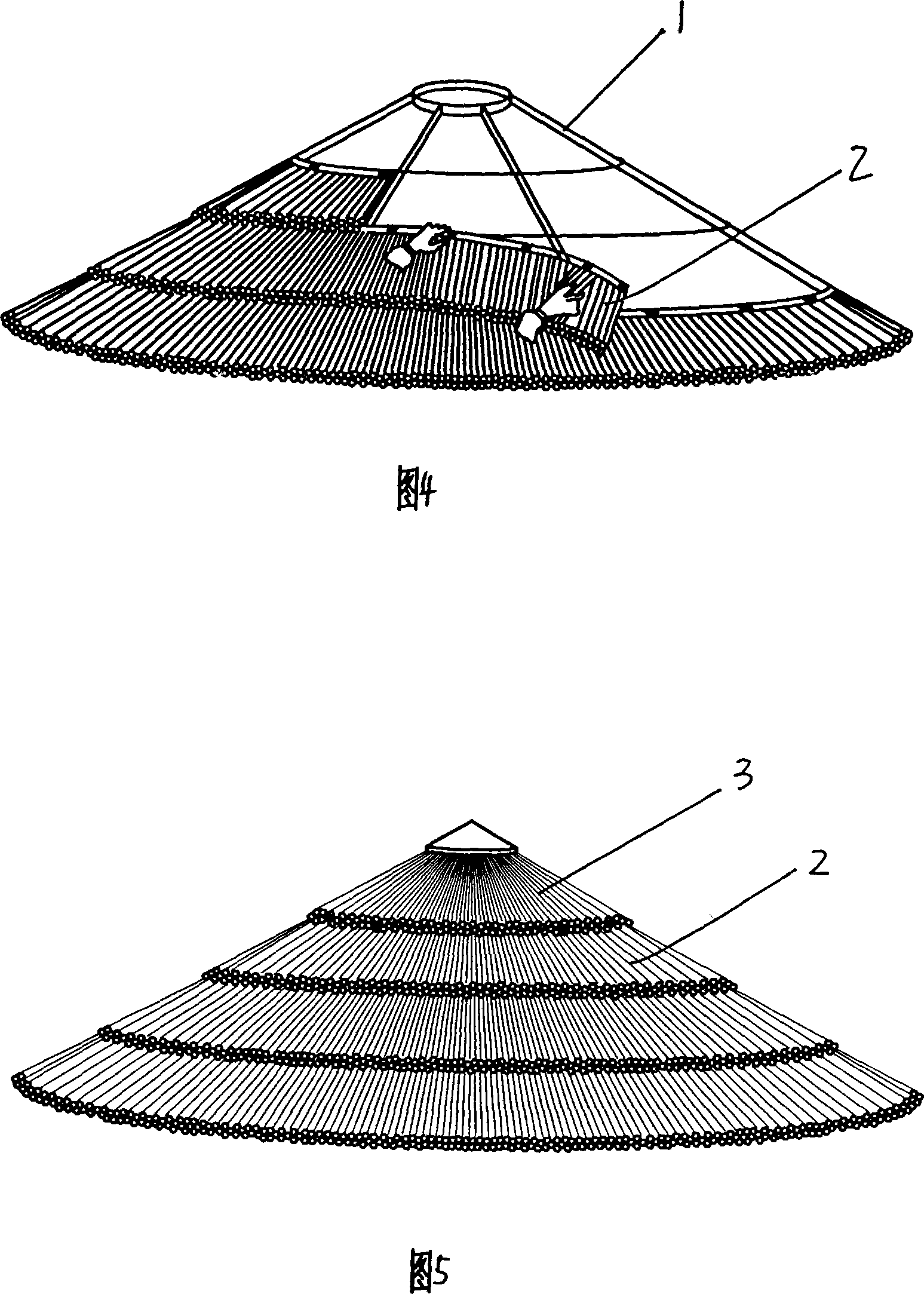

Plastics fibre housetop and manufacturing method therefor

InactiveCN101096870ANo pollutionBuilding roofsRoof covering using straw/thatchPlant fibreEngineering

The invention discloses a plastic fiber roof, which is characterized by the following: comprising roof frame; displaying laminated plastic fiber strip material block on the roof frame; reverse-putting plastic fiber tip cone on the top of the roof frame; allocating the same colour with plant fiber and straw; forming harmonious beauty.

Owner:YUZHOU CITY LVZHIZHOU GARDEN APPLIANCE MFG

Anti-thatch roof for amusement park area

PendingCN114837472AImprove connection strengthEasy to fixBuilding roofsGeneral water supply conservationEngineeringStructural engineering

The invention belongs to the technical field of simulation thatch houses, and particularly relates to a simulation thatch house roof for an amusement park area, which comprises a body, support columns, a roof framework, a fixing ring, thatch strips, a top cover and a waterproof device, and is characterized in that a coaming is fixedly mounted between two adjacent support columns by using bolts, so that the connection strength of the two adjacent support columns can be effectively enhanced; the overall structural strength of the body is synchronously improved, thatch strips are evenly and fixedly installed on the peripheral side of the top cover through locking rings, the fixing effect of the thatch strips is improved, and meanwhile the three-dimensional effect of the body can be improved; the thatch strip fixing device has the advantages that the thatch strip fixing device is simple in structure and convenient to operate, the thatch strip fixing effect can be improved, and the waterproof performance of the body can be effectively improved.

Owner:QITELE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com