Manufacturing method of waterproof thatch

A manufacturing method and technology of thatch, applied in building construction, roofing with straw/wheat straw, material gluing, etc., to improve the service life and aesthetics, and solve the effect of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

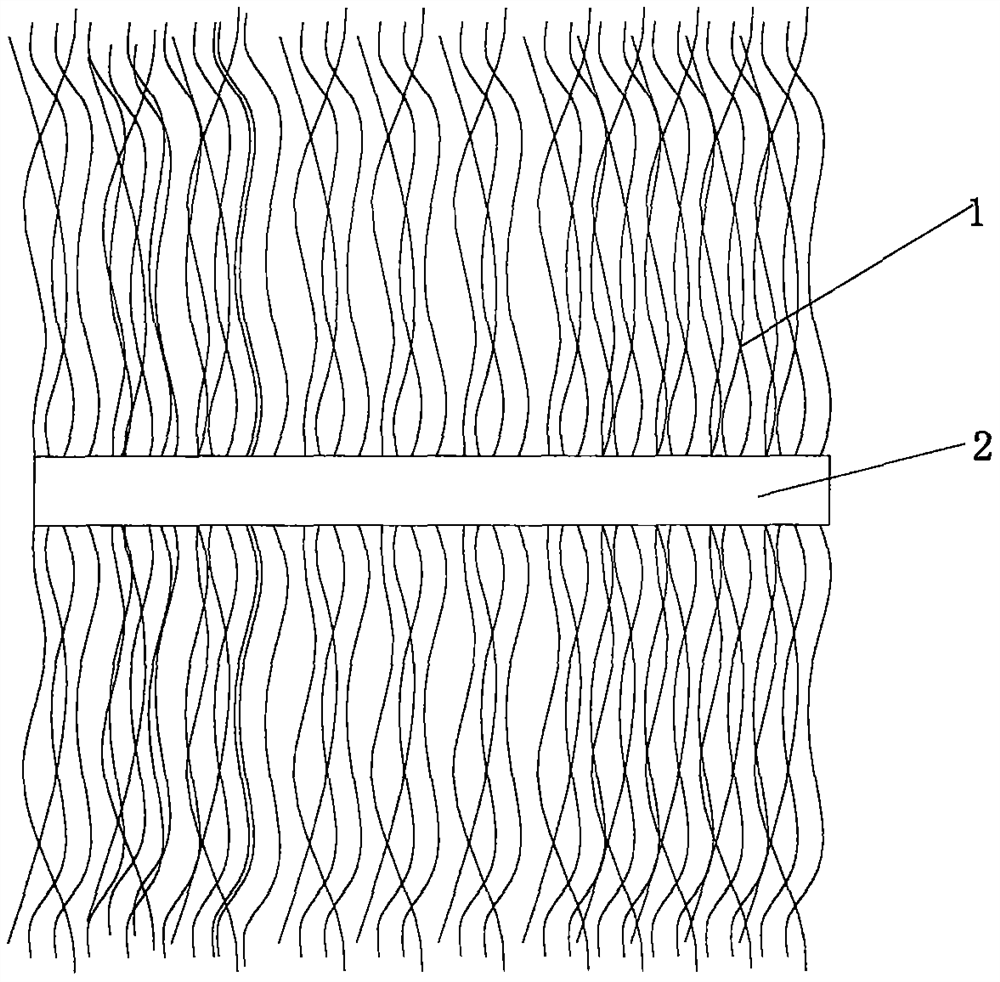

[0014] refer to figure 1 , the specific embodiment adopts the following technical scheme: a waterproof thatch and a manufacturing method, including the following steps: including the thatch 1, the middle of the thatch 1 is welded by hot melt adhesive; the said thatch 1 adopts plastic simulated thatch or aluminum simulated thatch .

[0015] A method for manufacturing waterproof thatch, comprising the following steps:

[0016] First put a plate of thatch on the warp beam of the machine through the tray, then start the machine, the warp beam rotates, and automatically perform mechanical extrusion. Fixed, so that the waterproof thatch is made, the length of the waterproof thatch can be cut arbitrarily, and the width can be lengthened or shortened ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com