Plastics fibre housetop and manufacturing method therefor

A technology of plastic fibers and manufacturing methods, which can be applied to roofs, roofs, building structures, etc., can solve the problems of not being able to achieve long-term use and viewing effects, being impractical, and unsightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

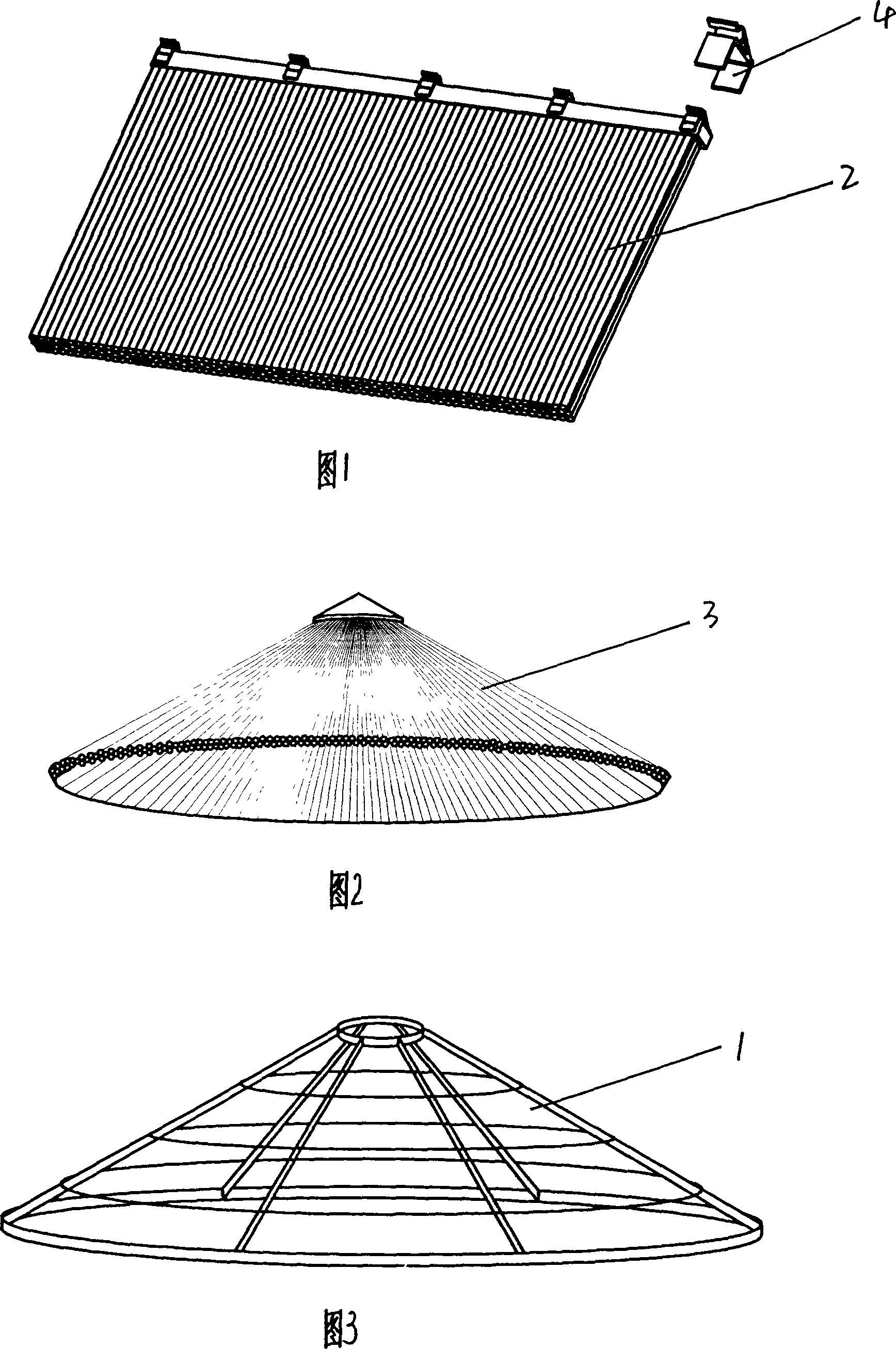

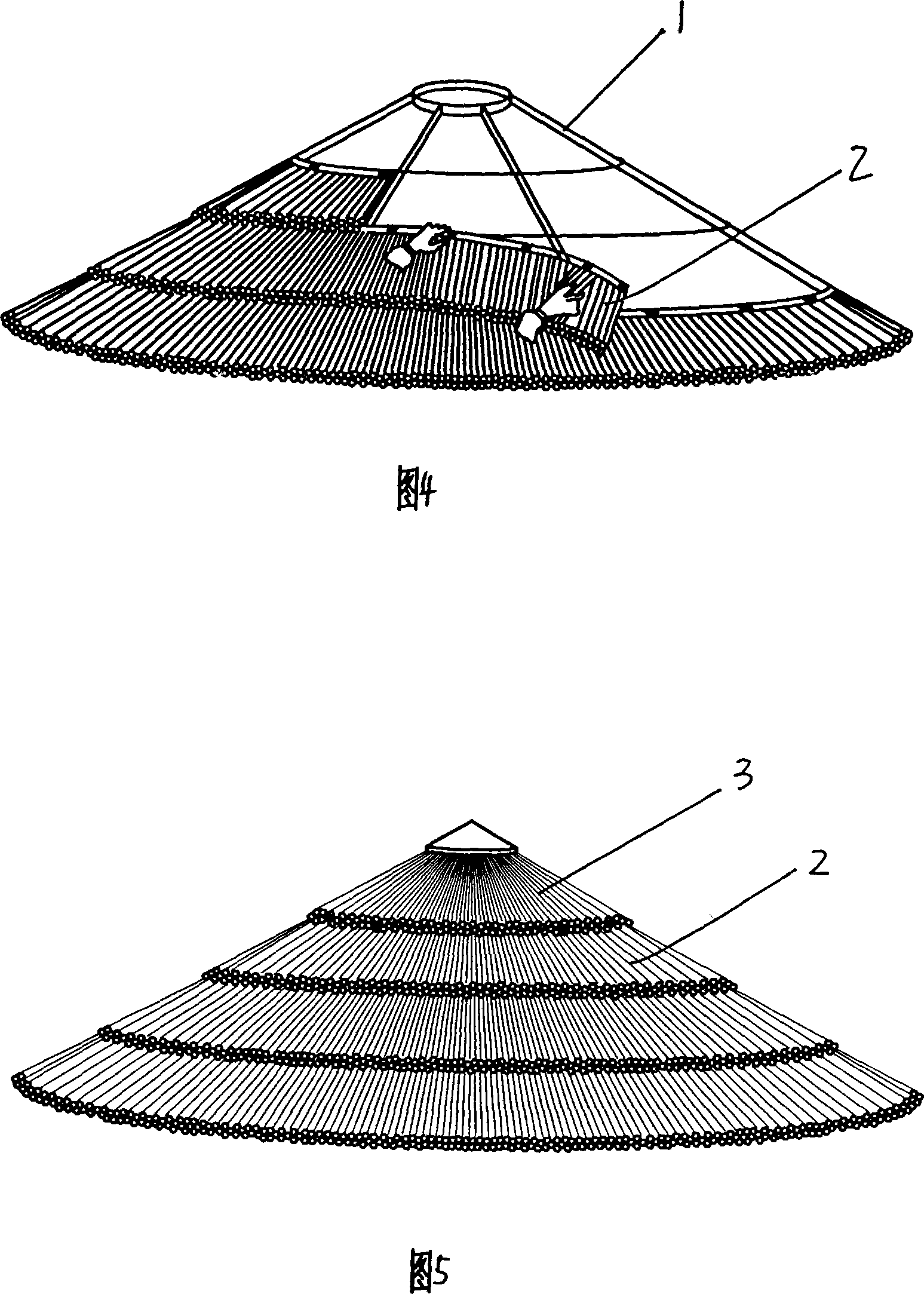

[0018] As shown in the figure, the present invention includes a roof frame 1 covered with a material block 2 made of plastic fiber strip material layer by layer on the roof frame, and a plastic fiber top cone 3 is buckled on the top of the roof frame. The material block 2 made of plastic fiber strip material is hooked on the roof frame by hooking 4, the side of the hook is the material block 2, and the other side of the hook is a hook hanging to the roof frame. The material block 2 that plastic fiber strip material is made also can be fixed on the fixing hole of roof frame by the mode of perforating. The roof frame is a frame made of metal welding or wood, and a frame made of other materials can also be used. A plurality of steel bars are welded on the metal frame, and the material block 2 made of plastic fiber strip material is hooked on the steel bars by hooking 4 . It is also possible to cover the rain-proof materials such as one deck of plastic sheeting and linoleum on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com