An exhaust rainproof cap with drainage and noise reduction structure

A technology of rain cap and exhaust hole, which is applied in the direction of exhaust device, muffler device, engine element, etc., can solve the problem of arranging the exhaust port on the top of the off-road military vehicle, and the exhaust direction is inclined upward or backward or inclined. Problems such as downward and backward discharge, engine flooding and flameout, limited wading height, etc., achieve the effect of beautiful appearance, reducing exhaust back pressure, and simplifying the direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

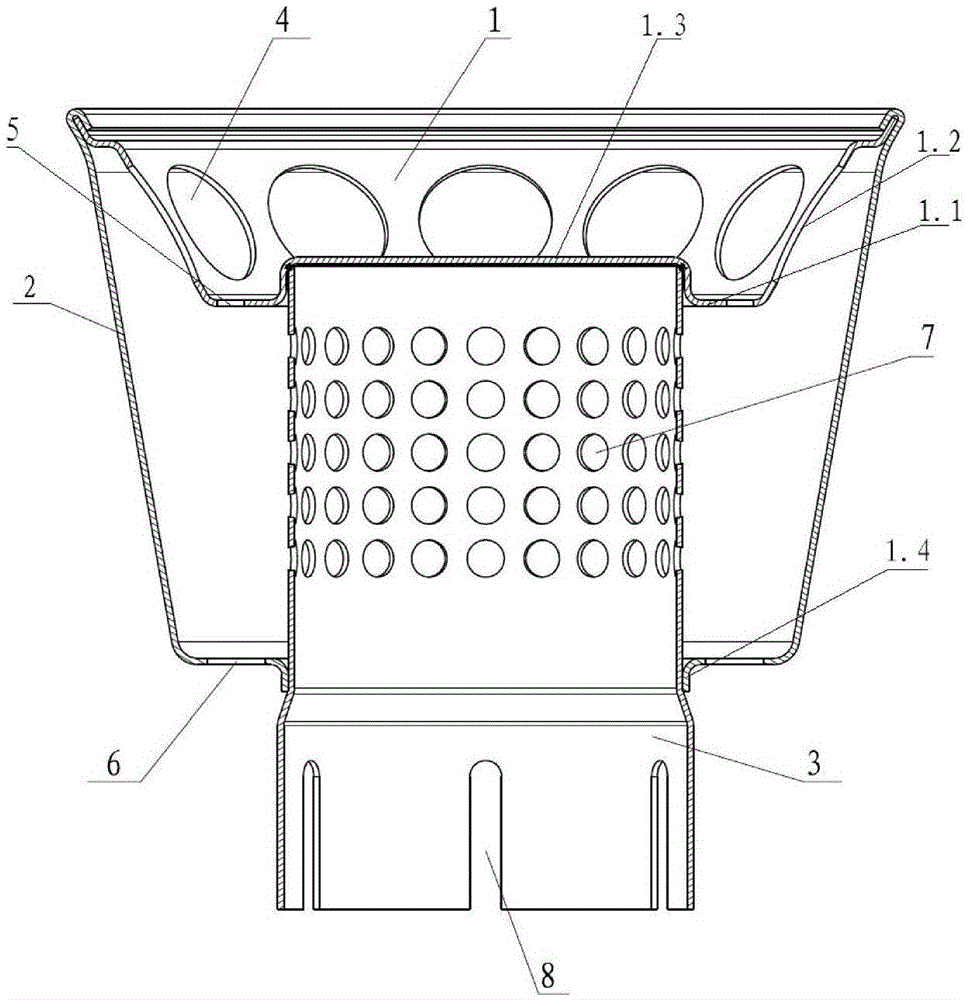

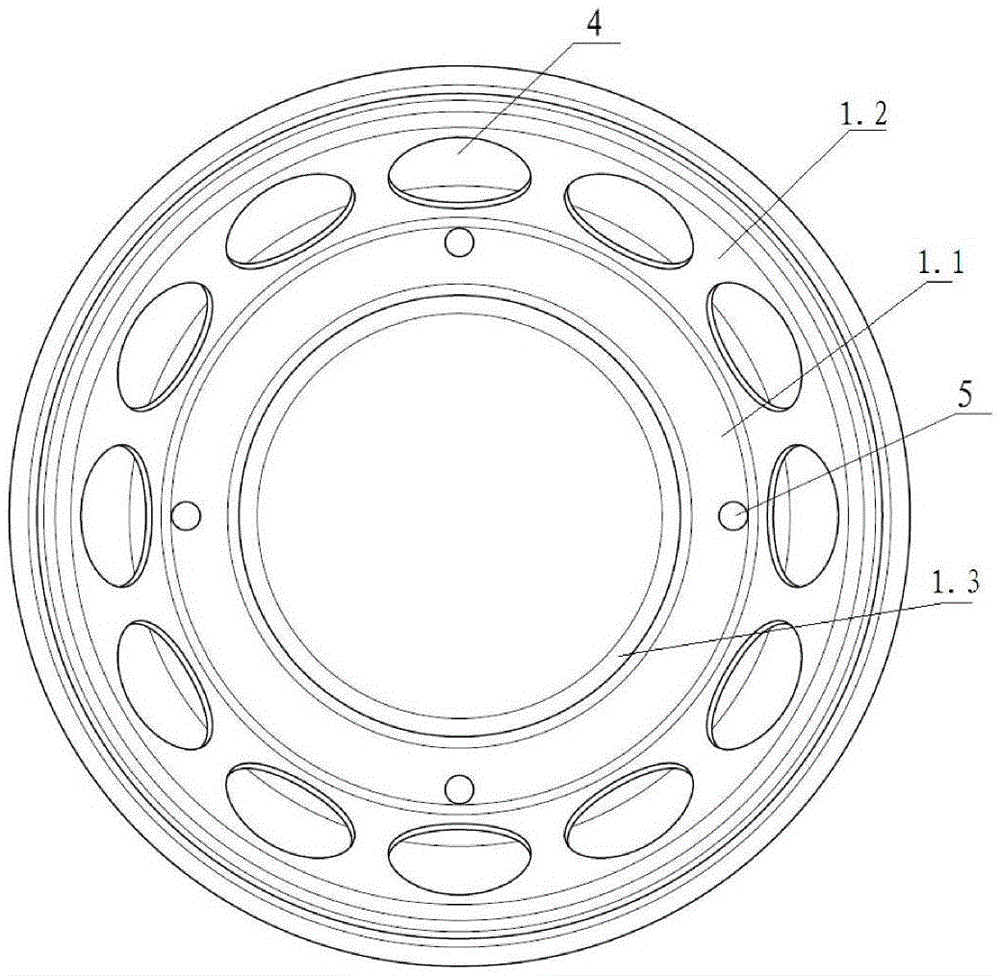

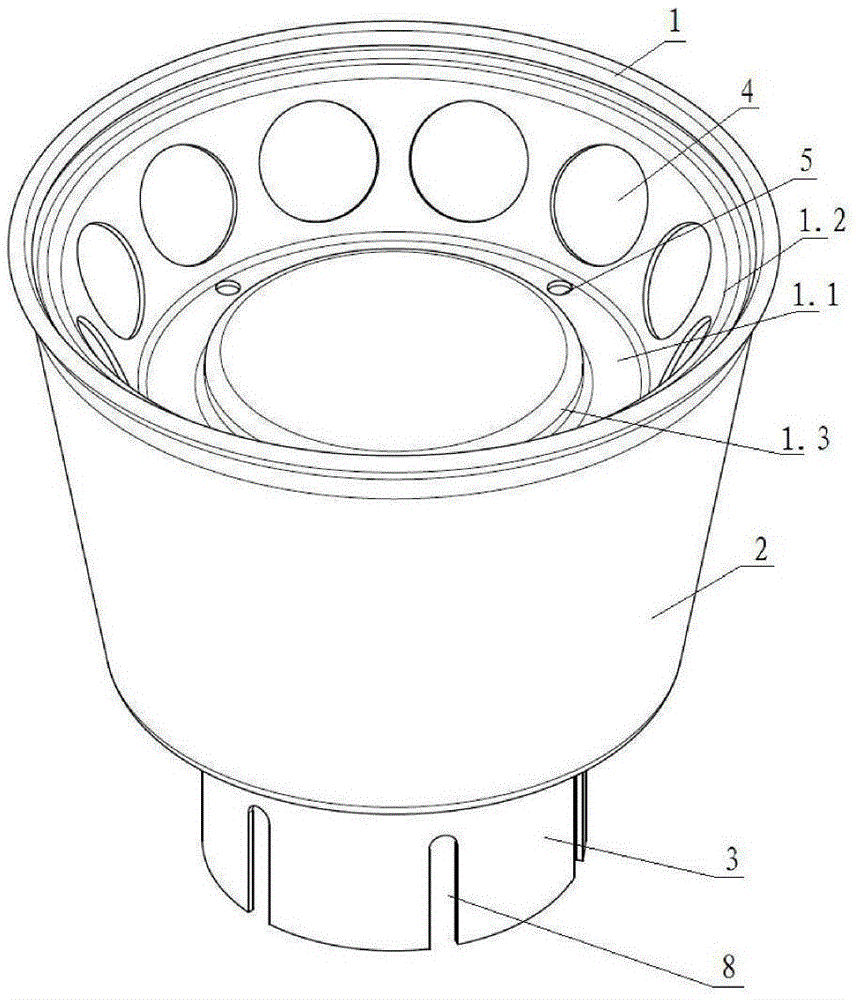

[0020] Embodiment one: if figure 1 — image 3 As shown, the end cover 1 includes a horizontal bottom cover 1.1 and an inclined side wall 1.2, the outer edge of the bottom cover 1.1 is connected to the lower edge of the side wall 1.2, and the upper edge of the side wall 1.2 is connected to the upper edge of the outer casing 2 , the vent hole 4 is set on the side wall 1.2, and the first water leakage hole 5 is set on the bottom cover 1.1. The lower side of the bottom cover 1.1 is provided with an upwardly recessed installation groove 1.3 for fitting connection with the top of the silencer pipe 3 .

Embodiment 2

[0021] Embodiment two: if Figure 5 As shown, the end cover 1 includes a bottom cover 1.1 and an inclined side wall 1.2, the upper edge of the side wall 1.2 is connected with the upper edge of the outer casing 2, and the lower edge of the side wall 1.2 is connected with the bottom cover 1.1; the bottom The cover 1.1 includes a central part 1.11, an obliquely arranged transition part 1.12 and a horizontal part 1.13 connected in sequence; the inner edge of the transition part 1.12 is connected to the central part 1.11, and the outer edge is connected to the horizontal part 1.13, and the exhaust hole 4 is arranged in the transition part 1.12; the inner edge of the horizontal part 1.13 is connected to the transition part 1.12, and the outer edge is connected to the side wall 1.2. The first water leakage hole 5 is arranged on the horizontal part 1.13. The central part 1.11 is an upwardly recessed structure for fitting connection with the top of the muffler pipe 3 .

[0022] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com