Internal storage and distribution pipe structure for oil inlet pipe and oil outlet pipe of oil cylinder of column type tablet machine

A technology for entering and exiting oil pipes and high-pressure oil pipes, which is applied in the directions of presses, mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of reducing the operating space between the four columns of the tablet press, high-pressure oil leakage of high-pressure oil pipes, and accidental damage of high-pressure oil pipes, etc. Achieve the effect of eliminating accidental damage, eliminating high-pressure oil leakage, and eliminating injury accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

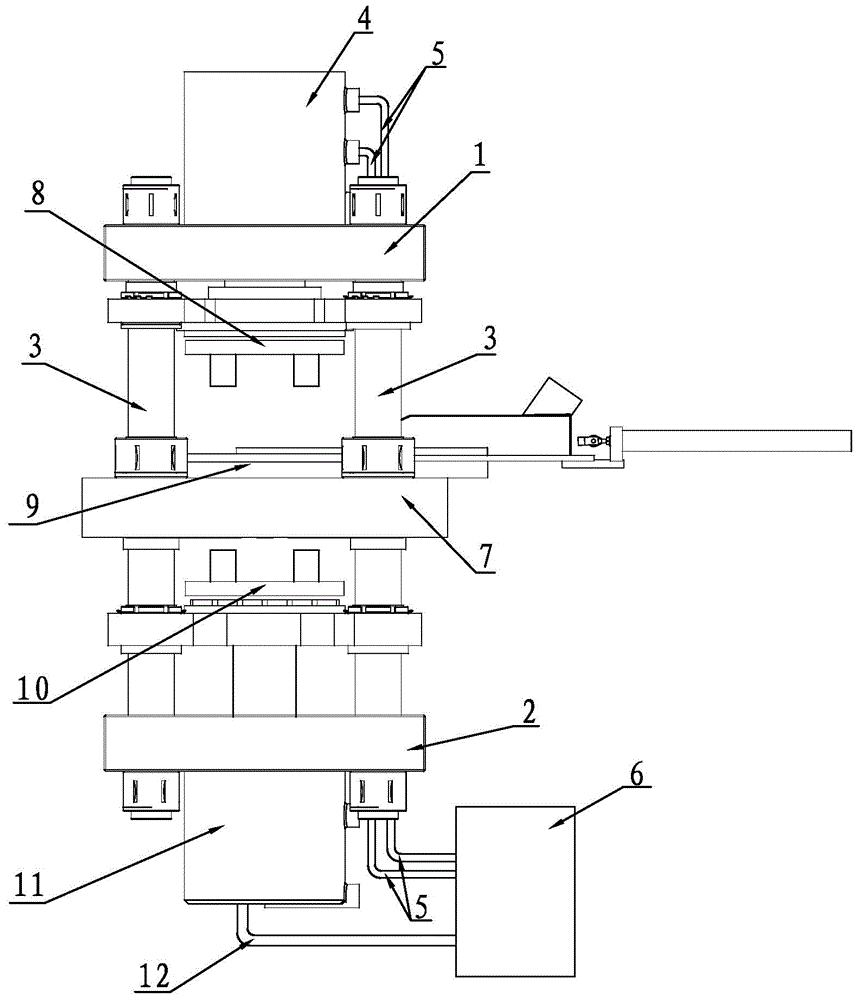

[0011] Embodiment 1: A kind of internal storage pipe structure of the oil cylinder inlet and outlet oil pipes of a column type tablet press machine, such as figure 1 As shown, it includes an upper fixed plate 1, a lower fixed plate 2, a guide column 3, an oil cylinder 4, a high-pressure oil pipe 5 and a hydraulic station 6, and the two ends of the guide column 3 are respectively fixed on the upper fixed plate 1 and the lower fixed plate 2, The two high-pressure oil pipes 5 on the oil cylinder 4 are sealed and connected with the hydraulic station 6, and all the guide columns 3 are hollow pipe structures, and the high-pressure oil pipes 5 pass through the hollow guide columns 3 and are sealed with the hydraulic station 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com