Double-power two-way composite sealing type low-temperature ball valve

A composite sealing and dual power technology, applied in shaft seals, valve details, valve devices, etc., can solve problems such as wear and maintenance costs, achieve high interchangeability, improve sealing performance, and reduce processing and assembly costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

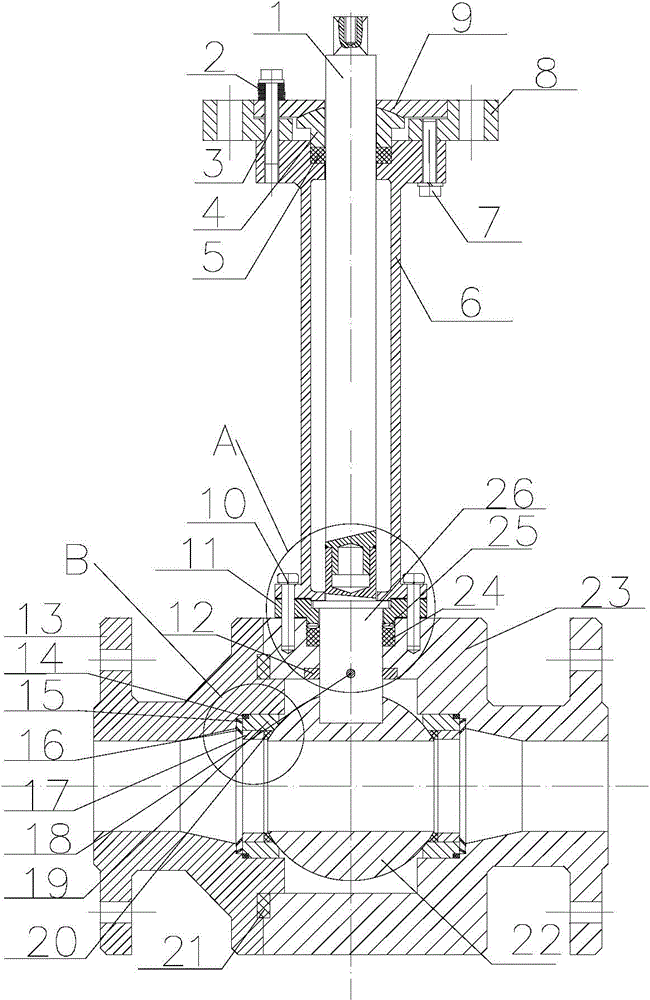

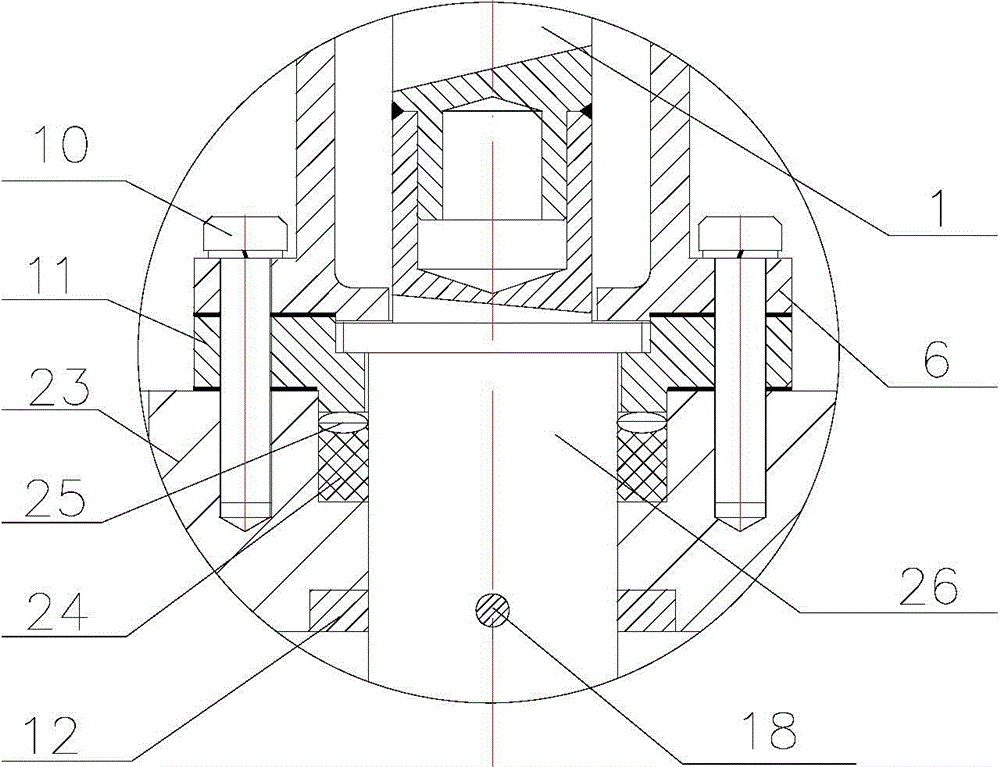

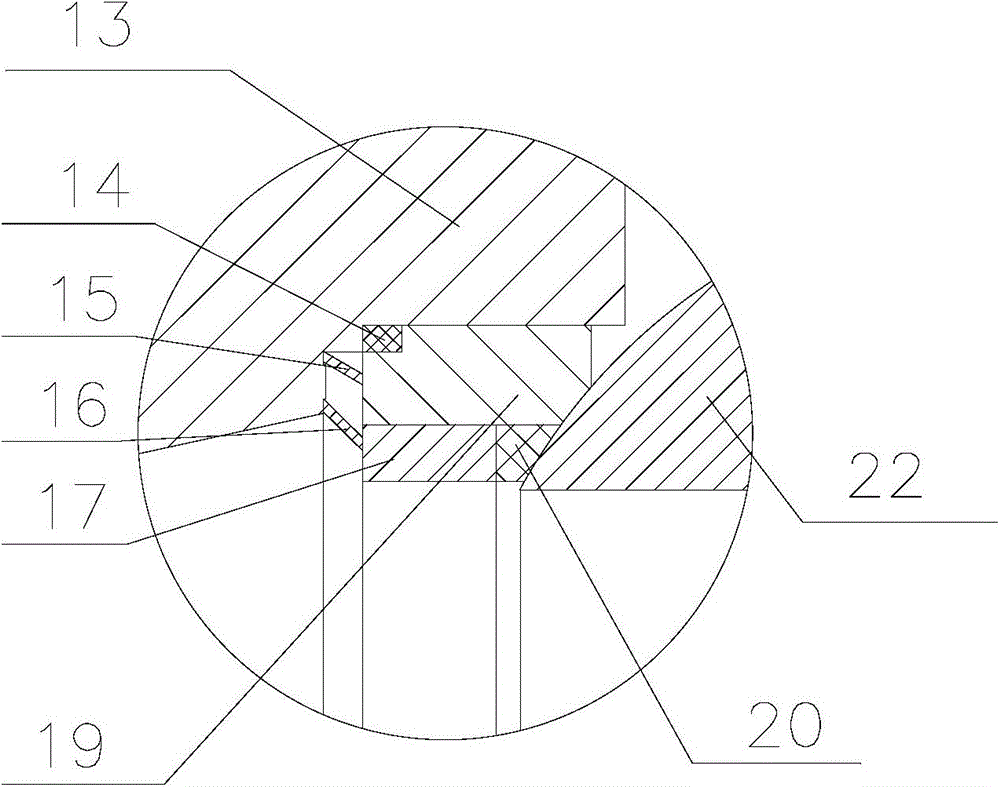

[0028] A dual-power two-way composite sealed cryogenic ball valve, the structure of which is as follows: figure 1 As shown, it includes a symmetrically arranged left valve body 13 and a right valve body 24, a valve core 22 arranged inside the valve body, a valve stem assembly, a soft-hard composite sealing assembly, a sealing packing assembly, and a positioning assembly.

[0029] The valve stem assembly is composed of an upper valve stem 1 and a lower valve stem 26. The upper valve stem 1 and the lower valve stem 26 are connected by welding, and the peripheral sleeve 6 is provided. The joint between the upper valve stem 1 and the lower valve stem 26 adopts a partially hollow structure. , the outer cylindrical surface of the hollow structure cooperates with the 26 shaft holes of the lower valve stem and reduces the low-temperature transmission of the low-temperature medium of the low-temperature valve. A driver installation disc 8 is installed on the sleeve 6, and the driver in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com