Non-phase change liquid gas digital filling device

A liquid gas, no phase change technology, applied in gas/liquid distribution and storage, equipment loaded into pressure vessels, container filling methods, etc., can solve the difficulties of manual operation, high energy consumption in the filling process, and filling efficiency Low-level problems, to achieve the effects of fast filling speed, improved efficiency and safety performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

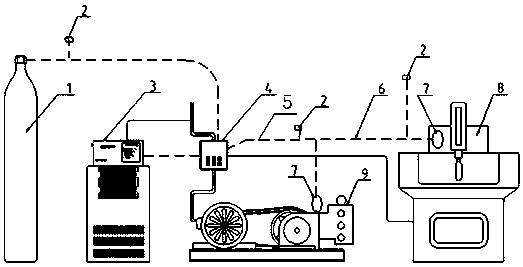

[0017] refer to figure 1 , the non-phase-change liquid gas digital filling device of the present embodiment, which includes a gas source 1, a temperature sensor 2, a digital phase-controlled constant temperature tank 3, a total control platform 4, a pipeline 5, a control signal line 6, an intelligent pressure gauge 7, Filling machine 8, digital phase control pressure pump 9, the gas source 1, digital phase control constant temperature tank 3, digital phase control pressure pump 9 and filling machine 8 are connected through pipeline 5, intelligent pressure gauge 7, digital phase control constant temperature Groove 3, digital phase-controlled pressure pump 9, temperature sensor 2 are connected to the main console 4 through the control signal line 6; the main control platform 4 collects the signals of the intelligent pressure gauge 7 and the temperature sensor 2, and the main control platform 4 is based on the pre-set Control the temperature of the digital phase-controlled consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com