Fixed-point quantitative liquid filling system for tank truck and liquid filling method thereof

A technology for tank trucks and tank trucks, which is applied to tank trucks, transmission systems, instruments, etc. It can solve the problems of potential safety hazards, poor liquid filling effect, and low efficiency, and achieve the effect of ensuring liquid filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

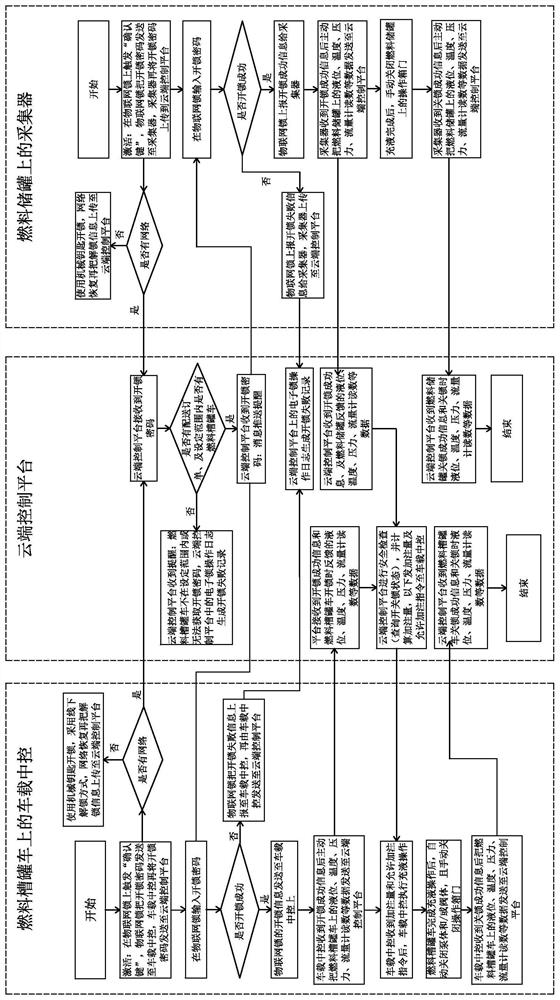

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] see figure 1 , the tank car fixed-point quantitative liquid filling system involved in this embodiment includes,

[0032] Fuel storage tank, used to store liquid fuel, the liquid fuel is LPG (liquefied petroleum gas); in order to reduce safety hazards and facilitate liquid filling, the fuel storage tank is generally placed in an outdoor environment;

[0033] Fuel tank trucks, used for liquid-phase refueling (filling) of fuel storage tanks;

[0034] The cloud control platform is used to complete tasks such as receiving data, processing data, recording data, issuing liquid filling instructions, and calculating liquid phase fuel filling volume; and the cloud control platform can monitor multi-unit fuel storage tanks and fuel tank trucks;

[0035] The service terminal controls the fuel tanker to reach the location of the target fuel storage tank ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com