Fixed train lifting overhauling device with complete train weighing function

A maintenance device, fixed technology, applied in the direction of lifting device, measuring device, weighing, etc., can solve problems such as no consideration, equipment occupying a large work site, and complicated work process, so as to prevent rollover and ensure accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

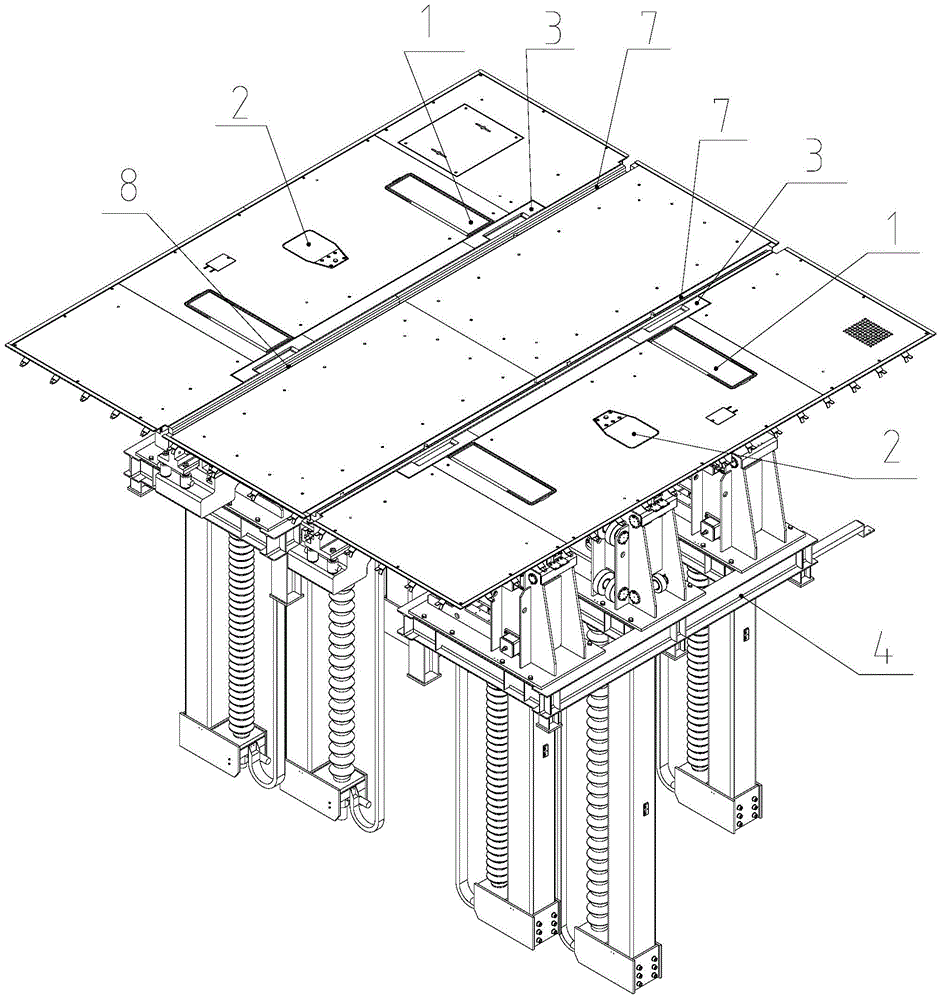

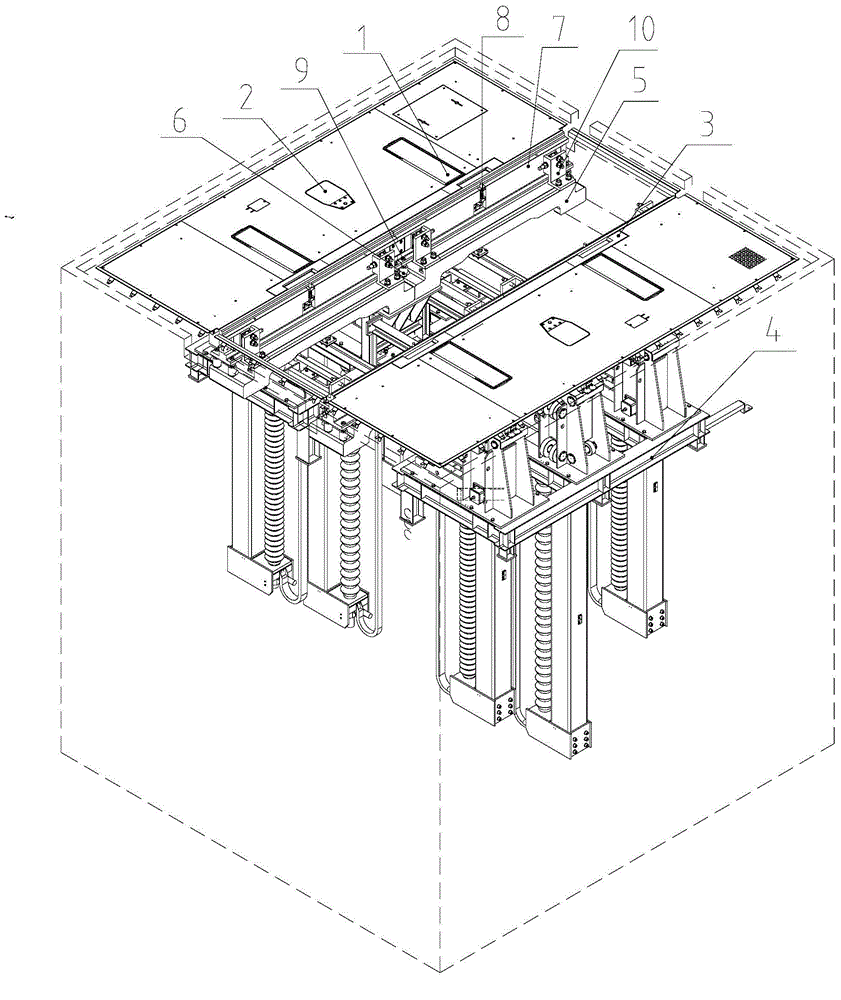

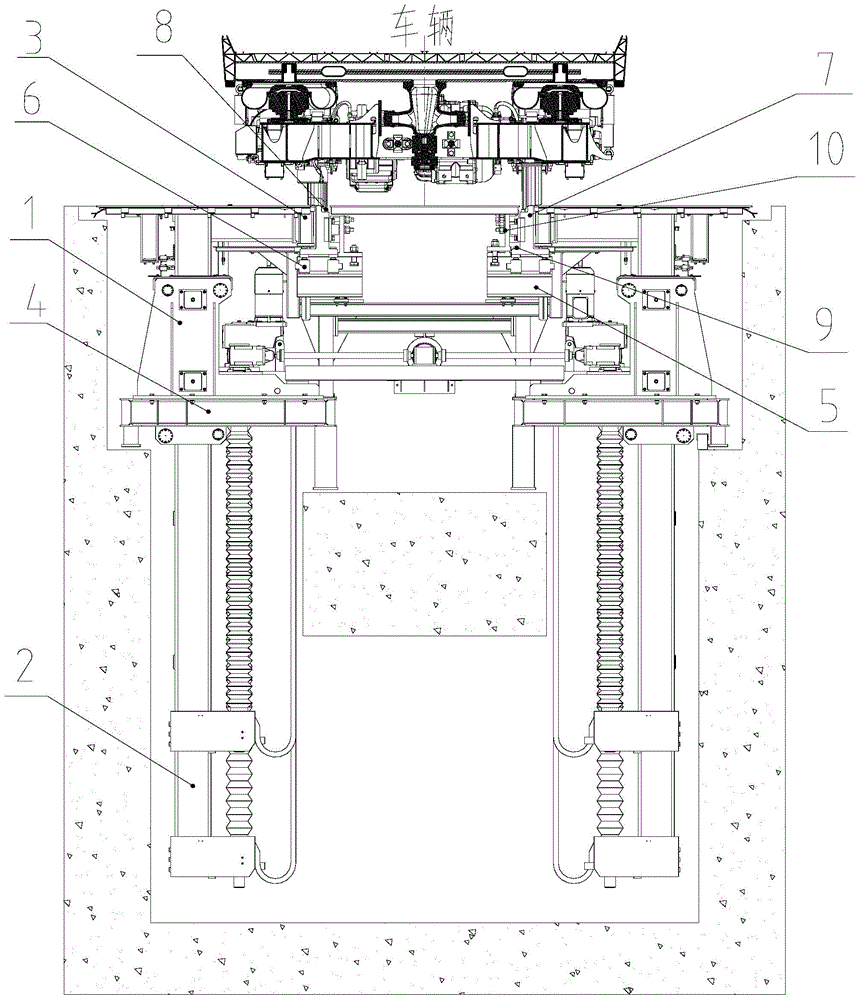

[0033] The fixed frame truck inspection and repair device with the whole vehicle weighing function is installed in the foundation pit, and completes the vehicle weighing operation and the vehicle inspection operation at the same station on both sides of the track.

[0034] See Figure 1-Figure 5 ,among them figure 2 Schematic diagram of the structure of hiding the middle cover for the maintenance device. The fixed frame car inspection and repair device with the complete vehicle weighing function mainly includes a bogie lifting mechanism, a car body lifting mechanism, a steel structure bearing platform 4 and a weighing unit module. The bogie lifting mechanism, the car body lifting mechanism and the weighing unit module are all installed on the steel structure bearing platform 4 on both sides of the track, and the steel structure bearing platform 4 is fixed to the civil engineering platform in the foundation pit.

[0035] The bogie lifting mechanism includes four bogie lifting colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com