Space distributive type camera boresight included angle measurement method

A camera boresight and test method technology, applied in the field of aerospace optical remote sensors, can solve problems such as difficulty and large scale, and achieve the effects of improving test accuracy, meeting system integration requirements, and shortening the test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

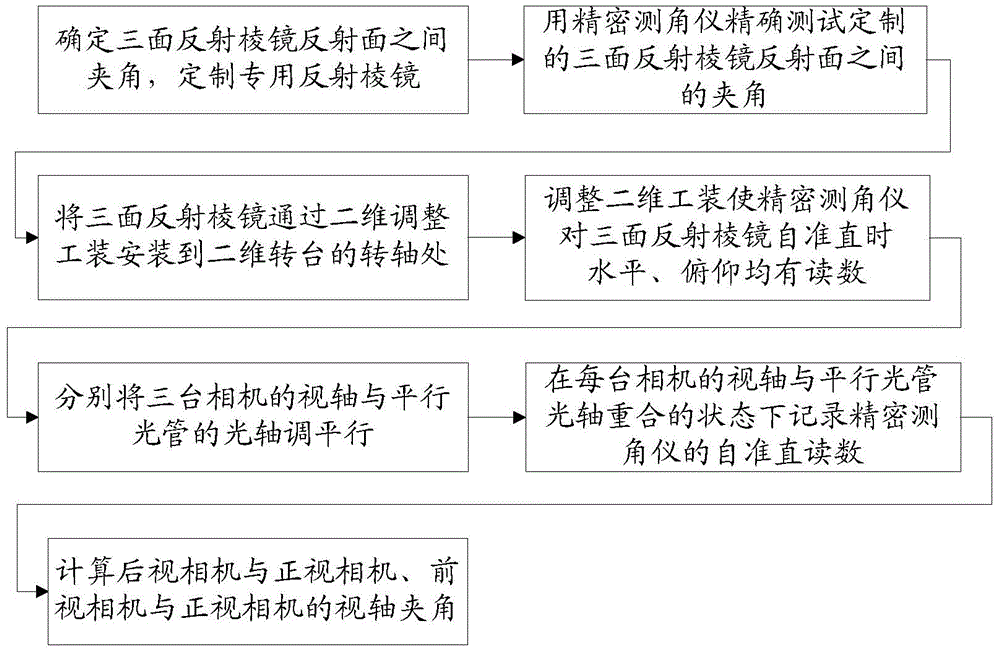

[0022] The basic idea of the present invention is: to realize the included angle test of visual axes of spatially distributed cameras by using a three-sided reflective prism and a high-precision precision goniometer. The installation location of the test equipment is as Figure 4 As shown, the specific implementation is as follows:

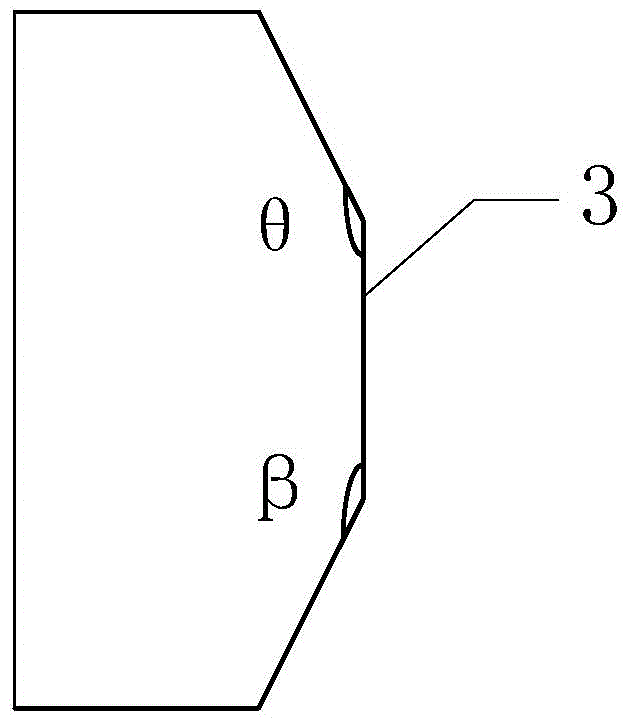

[0023] Step (1) determines the angle between two adjacent reflective surfaces in the three-sided reflective prism 3, so that the angle between the adjacent reflective surfaces of the three-sided reflective prism 3 is 180°-Φ; where Φ is the phase in the three-line array camera 2 to be measured The design value of the viewing axis angle of adjacent cameras;

[0024] Step (2) Use the precision goniometer 1 to test the actual values of the two included angles θ and β of the adjacent reflective surfaces of the three-sided reflective prism 3, such as image 3 As shown, θ and β are the actual test values of the angle between adjacent reflective s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com