Halogen bulb provided with double layers of glass bodies

A double-glazed, halogen bulb technology, applied in the shell/tube shell of the luminous body, the sealing between the tube shell components, sustainable construction, etc. To achieve the effect of convenient installation or replacement of bulbs, safe and reliable use, and prolonged service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

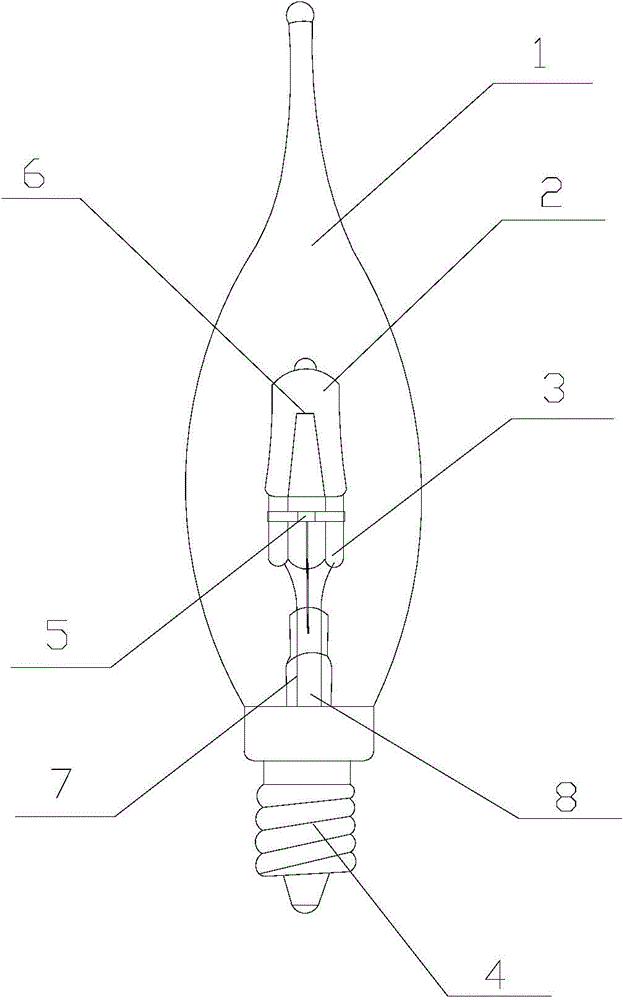

[0010] Such as figure 1 As shown, the double-layer vitreous halogen bulb includes an inner glass bulb 2, a filament 6, a glass splint 3, a filament connecting piece and a connecting wire 7, the inner glass bulb 2 is provided with a filament 6 and is connected to the glass splint 3, and the filament is connected The sheet is set in the glass splint 3 and connected with the connecting wire 7 protruding from the glass splint 3, the inner glass bubble 2, the glass splint 3 and the connecting wire 7 are all arranged in the outer glass bubble 1, and one end of the outer glass bubble 1 A lamp cap 4 is provided, the other end is closed, and a connecting wire 7 is connected to the lamp cap 4 so that the filament 7 and the lamp cap 4 form an electrical connection. In this embodiment, a splint bracket 5 is also provided on the glass splint 3, the splint bracket 5 is connected with the glass column 8 of the lamp cap and the glass splint 3 and the inner glass bubble 2 are fixed in the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com