Assembly mold and assembly method of commutator

An assembly method and commutator technology, which are applied to electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of heavy weight of the transition plate and the middle sleeve plate, high use cost of the transition plate, and increased production cost, etc. The effect of structure optimization, high assembly efficiency and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

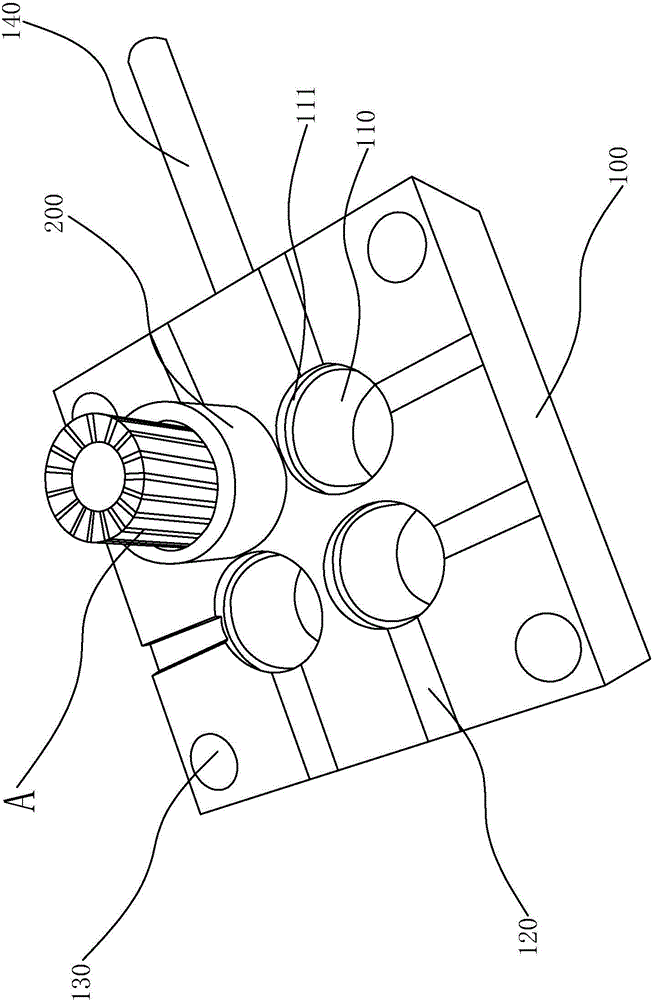

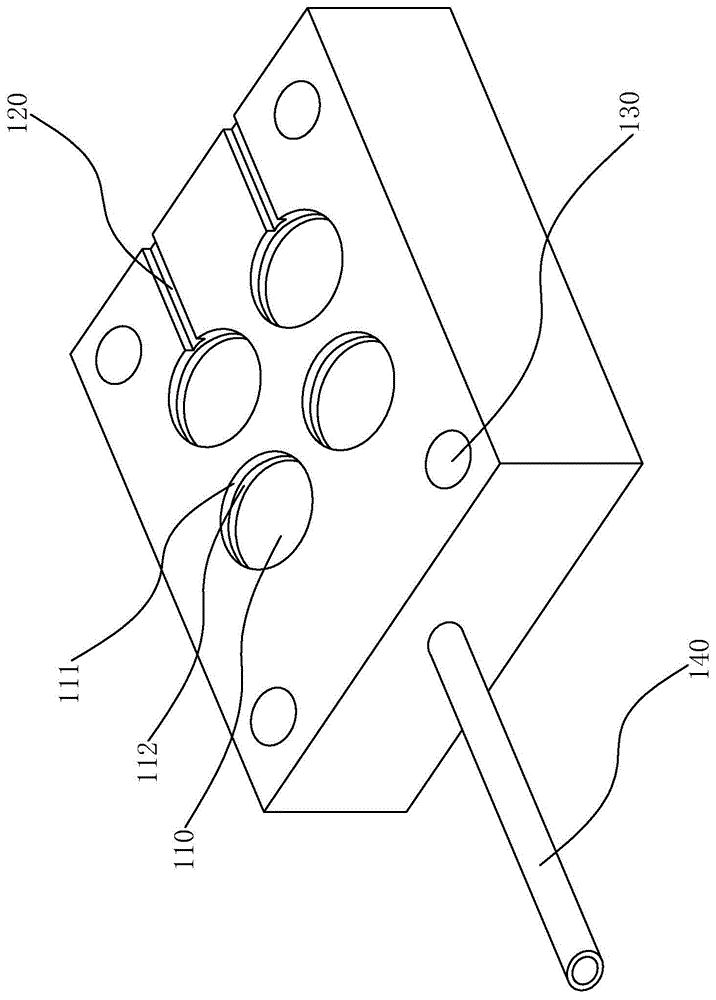

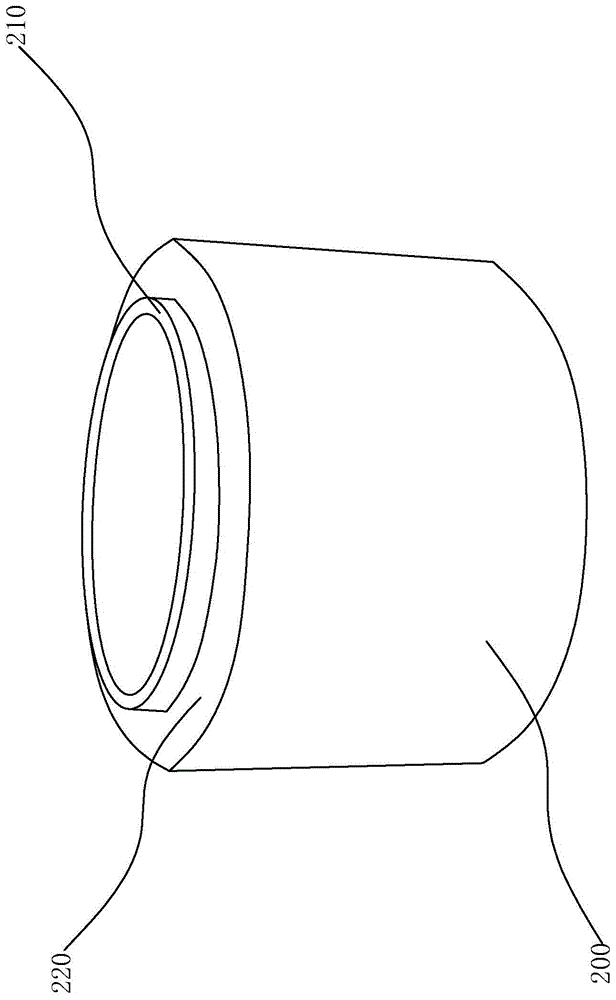

[0031] Such as figure 1 As shown, a commutator assembly mold includes a middle sleeve plate 100 and a positioning guide sleeve 200, the middle sleeve plate 100 is square, and the positioning guide sleeve 200 is circular tubular.

[0032] Such as figure 1 , figure 2 , Figure 4 , Figure 5 As shown, four assembly holes 110 that penetrate the middle casing 100 and are used to accommodate the commutator are opened on the middle casing 100, and the center line of the four assembly holes 110 forms a square. Of course, the assembly holes 110 The number is set according to actual needs, which can be more than four or less than four. Four coaxial countersunk holes 111 corresponding to the assembly holes 110 are provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com