Rapid leak detection device of bipolar plate of fuel cell and method thereof

A fuel cell, bipolar plate technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc., can solve the problem of reduced equipment robustness, long time, and complex sealant lines and other problems to achieve the effect of reducing the impact of accuracy and precision, meeting the needs of production takt, and simplifying sealing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

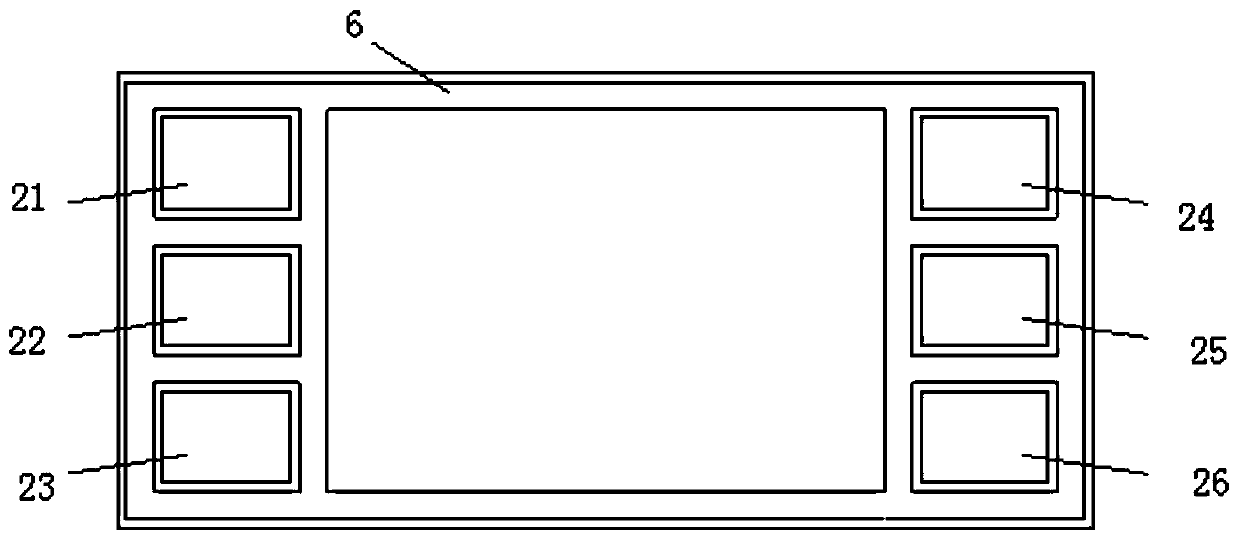

[0034] Such as figure 1 As described above, a fuel cell bipolar plate 2 is composed of an anode plate and a cathode plate. The space between the anode plate and the cathode plate is a cooling channel cavity. Two ends of the bipolar plate are provided with three inlets and three outlets, which are respectively: Fuel inlet 21, cooling fluid inlet 22, oxidant inlet 23, oxidant outlet 24, cooling fluid outlet 25, fuel outlet 26, bipolar plate sealing groove 6 is provided on the surface of the bipolar plate.

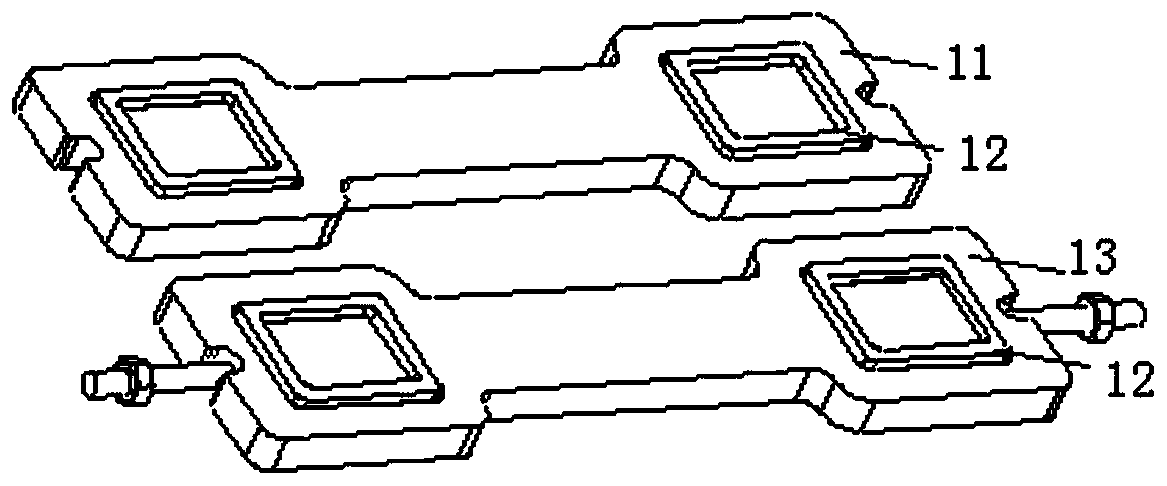

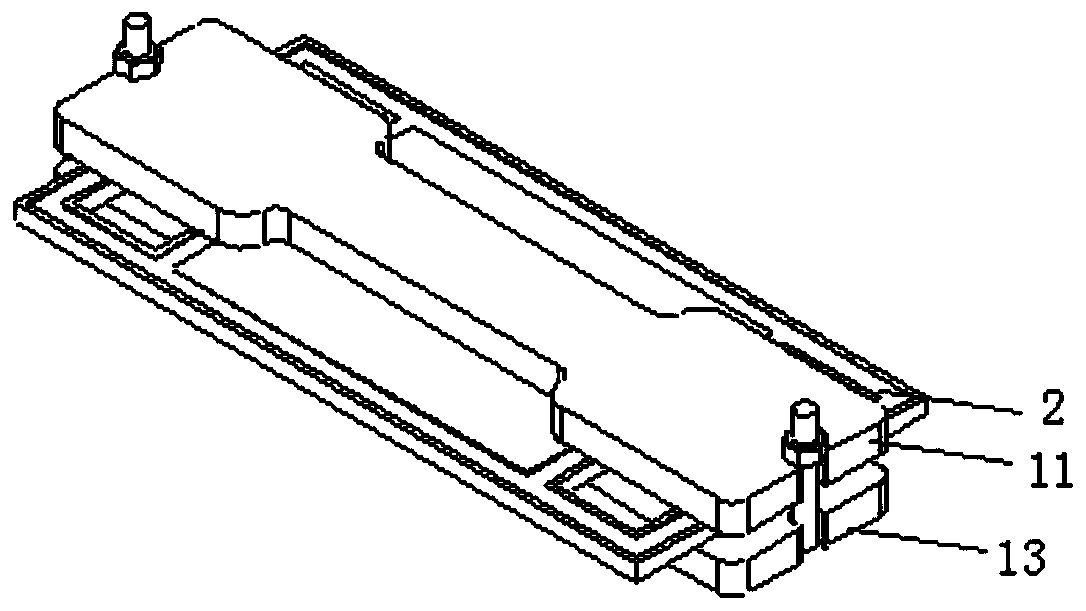

[0035] In order to test the sealing performance of the above-mentioned bipolar plate, a special fixture 1 is designed, and its structure is as follows: Figure 2~3 As shown, it includes an upper splint 11, a seal 12 and a lower splint 13 with fastening bolts. Both ends of the upper splint 11 and the lower splint 13 are provided with seals 12 that match the cooling fluid inlet and outlet of the bipolar plate. The bipolar plate is placed on the lower splint 13, a groove is pro...

Embodiment 2

[0042] A fast leak detection method for a fuel cell bipolar plate, comprising the following steps:

[0043] 1. Fix the fuel cell bipolar plate through the fixture, and then put it into the buffer cabin. After closing the buffer cabin, open the vacuum valve, and use the vacuum pump to evacuate the buffer cabin to a vacuum degree of 2000 Torr;

[0044] 2. Open the helium inlet valve of the helium gas source and the helium valve on the pipeline connecting the helium chamber and the buffer chamber, so that the helium chamber and the buffer chamber are filled with helium to keep the pressure in the helium chamber and the buffer chamber Internal pressure balance; the pressure in the helium chamber is 250KPa;

[0045] 3. Open the fixture inlet valve of the nitrogen gas source and the fixture outlet valve connected with the gas detection equipment, fill the fixture with high-purity nitrogen, completely dilute the existing air in the cavity where the cooling channel inside the bipolar ...

Embodiment 3

[0048] A fast leak detection method for a fuel cell bipolar plate, comprising the following steps:

[0049]1. Fix the bipolar plate of the fuel cell through the fixture, and then put it into the buffer cabin. After closing the buffer cabin, open the vacuum valve, and use the vacuum pump to evacuate the buffer cabin to a vacuum degree of 3000 Torr;

[0050] 2. Open the helium inlet valve of the helium gas source and the helium valve on the pipeline connecting the helium chamber and the buffer chamber, so that the helium chamber and the buffer chamber are filled with helium to keep the pressure in the helium chamber and the buffer chamber Internal pressure balance; the pressure in the helium chamber is 400KPa;

[0051] 3. Open the fixture inlet valve of the nitrogen gas source and the fixture outlet valve connected with the gas detection equipment, fill the fixture with high-purity nitrogen, completely dilute the existing air in the cavity where the cooling channel inside the bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com