A Power Topology for Simultaneous Control of Three Switched Reluctance Motors

A technology for simultaneous control of switched reluctance motors, applied in multiple motor speed/torque control, etc., can solve the problem of increasing the development cost and hardware cost of power converters of switched reluctance motors, the inability to mass-produce, and the increase of switched reluctance Problems such as the complexity and cost of the motor power converter, to achieve the effect of shortening the product development cycle, improving the utilization rate of the winding, and making it easy to purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings.

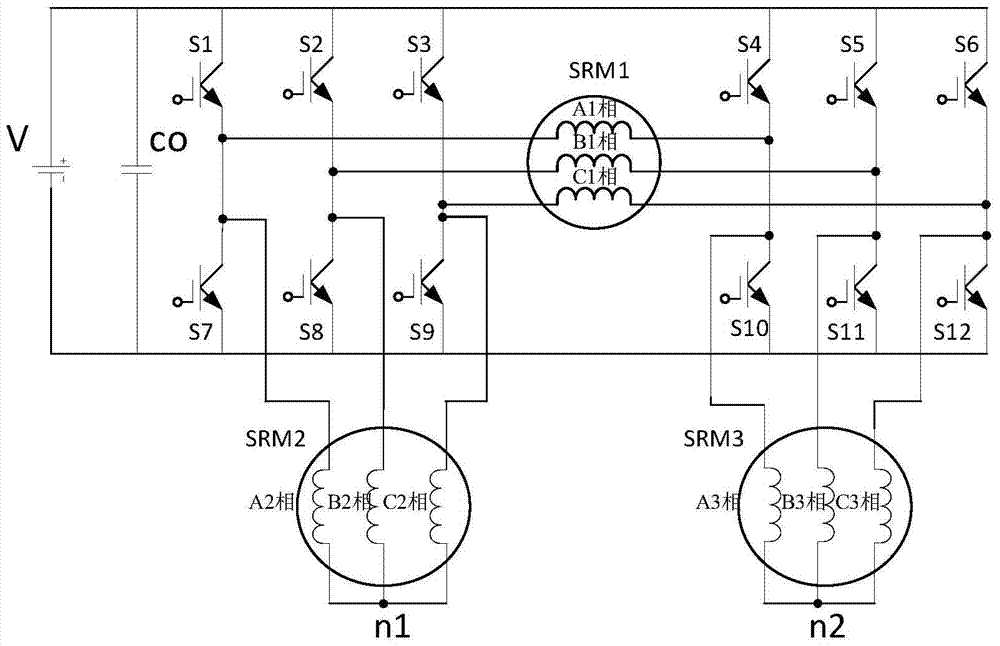

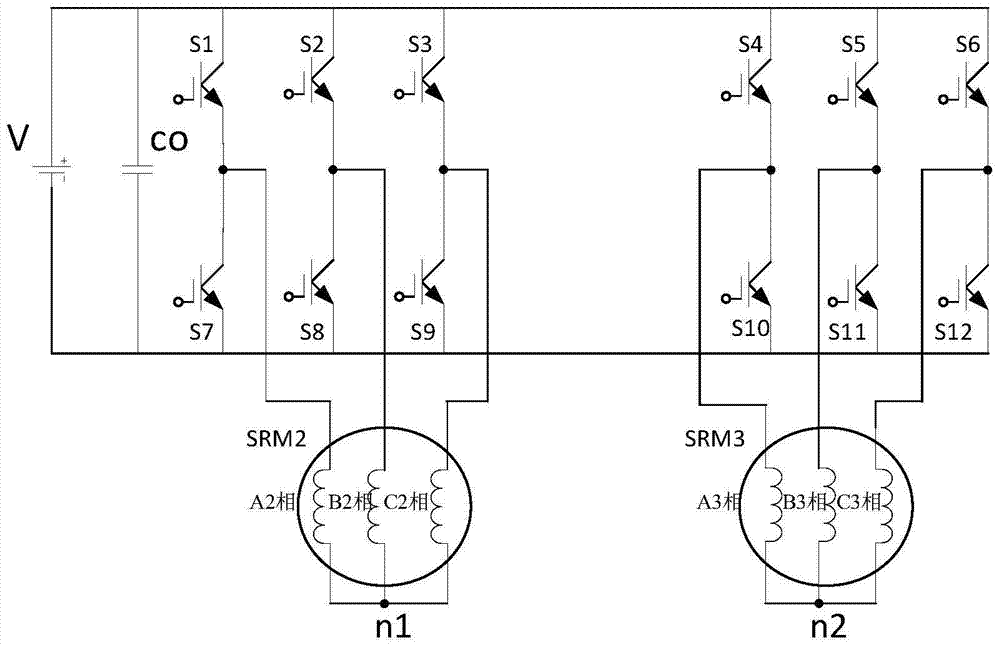

[0024] Such as figure 2 As shown, the present invention provides a power topology for simultaneously controlling three switched reluctance motors, mainly two three-phase bridge converters controlling the power topology for three three-phase switched reluctance motors, including DC power supply V, power supply Filter capacitor CO, 12 power switch tubes S1-S12, three three-phase switched reluctance motors No. 1 motor SRM1, No. 2 motor SRM2, and No. 3 motor SRM3.

[0025] No. 1 motor SRM1 includes A1 phase winding, B1 phase winding, C1 phase winding; No. 2 motor SRM2 includes A2 phase winding, B2 phase winding, C2 phase winding, No. 3 motor SRM3 includes A3 phase winding, B3 phase winding, C3 phase winding ; Neutral point n1, n2.

[0026] The power supply filter capacitor CO is connected in parallel to the two poles of the DC power supply V, and the positive pole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com