New fat blend composition

A technology of fat blends and compositions, which is applied in the direction of extended composition, fatty acid esterification, edible oil/fat, etc., which can solve problems such as poor crystallization performance, slow melting characteristics of spread fat, poor melting performance, etc., and achieve cholesterol The effect of level reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Example 1 - Method of preparing a fat blend composition according to the invention.

[0106] Hard stock for pilot scale experiments was prepared from refined and deodorized fat and oil raw materials by using chemical transesterification.

[0107] The chemically transesterified hard pulp was further decolorized and deodorized on a pilot scale.

[0108] The fat blend for the spread fat pilot scale test was prepared by blending deodorized hard stock and liquid oil.

[0109] The oils were blended at a temperature of 60°C, at which temperature all parts of the fat blend were liquid.

[0110] chemical transesterification

[0111] Chemical transesterification was carried out in a 2000ml three-neck round bottom flask. The bottle mouth in the middle is connected with the vacuum pump. Insert a thermometer into the mouth of the second bottle to detect the reaction temperature. The third bottle mouth is covered with a cap.

[0112] The flask containing the hard slurry ingred...

Embodiment 2

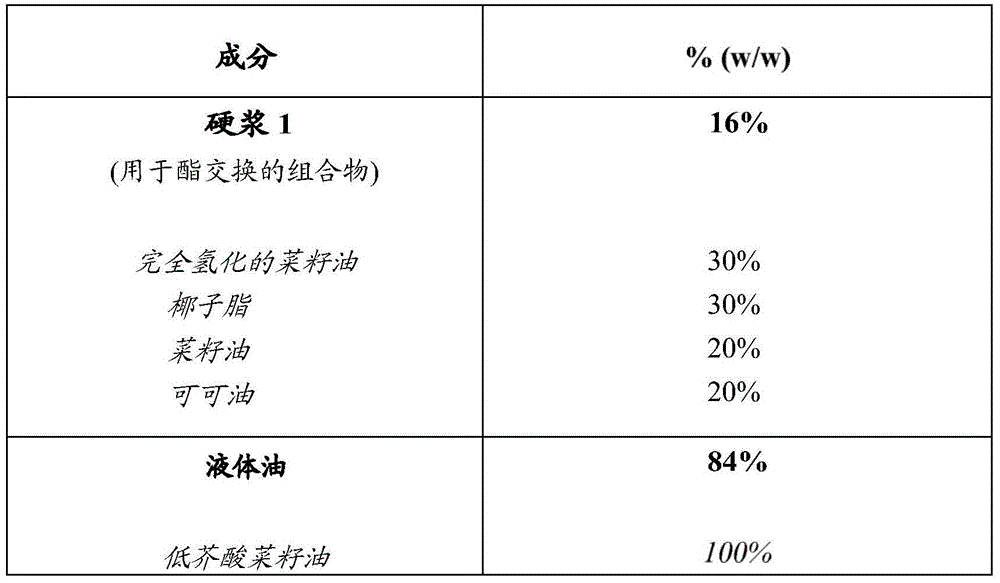

[0127] Example 2 - Fat Blend 1 Composition

[0128] Fat Blend 1 was prepared according to the method of Example 1.

[0129] The composition of the obtained fat blend 1 is shown in Table 1.1 below.

[0130]

[0131] Table 1.1 - Fat Blend 1

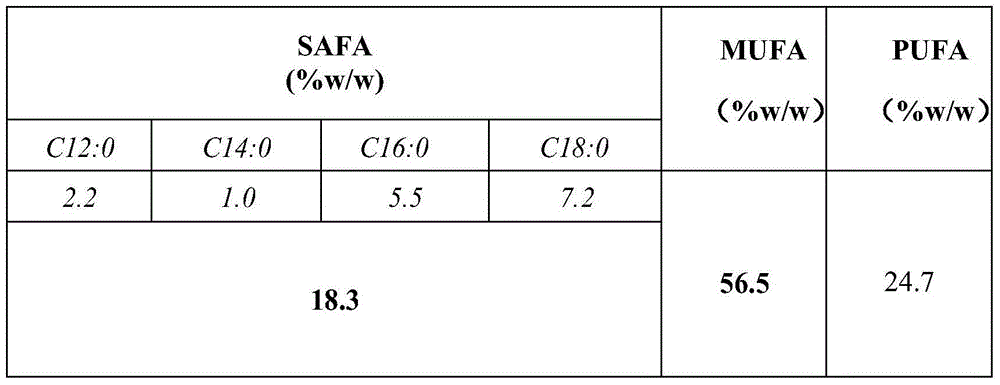

[0132] The exact content of Fat Blend 1 in saturated fatty acids (SAFA), monounsaturated fatty acids (MUFA) and polyunsaturated fatty acids (PUFA) is shown in Table 1.2 below.

[0133] Fat Blend 1 further contained 0.5% trans fatty acids.

[0134]

[0135] Table 1.2 - Fat Blend 1

Embodiment 3

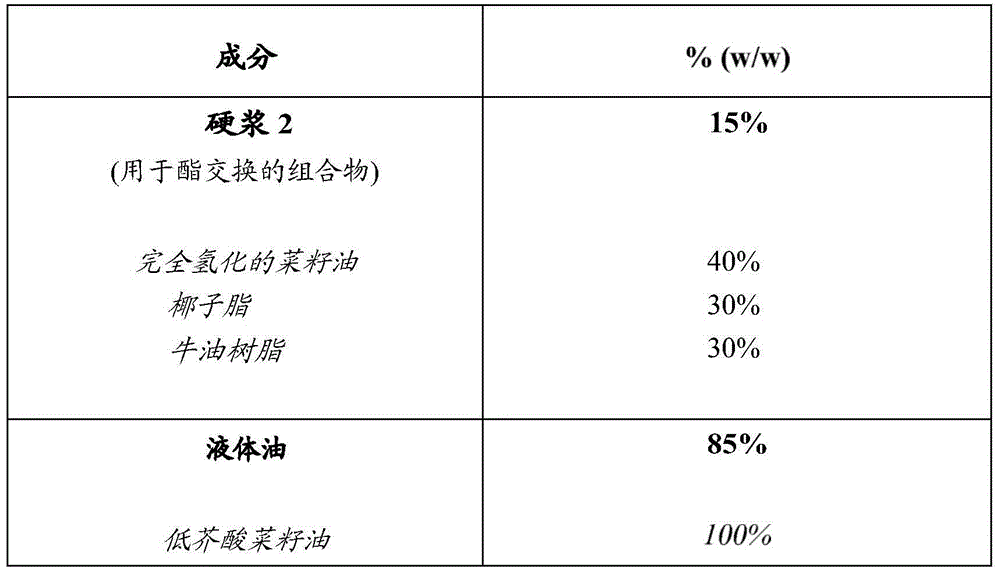

[0136] Example 3 - Fat Blend 2 Composition

[0137] Fat Blend 2 was prepared according to the method of Example 1.

[0138] The composition of the obtained fat blend 2 is shown in Table 2.1 below.

[0139]

[0140] Table 2.1 - Fat Blend 2

[0141] The exact content of Fat Blend 2 in saturated fatty acids (SAFA), monounsaturated fatty acids (MUFA) and polyunsaturated fatty acids (PUFA) is shown in Table 2.2 below.

[0142] Fat blend 2 further contained 0.5% trans fatty acids.

[0143]

[0144] Table 2.2 - Fat Blend 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com