Nonwoven Laminates

一种非织造布、熔喷非织造布的技术,应用在非织造布、纺织品和造纸、纺织等方向,能够解决聚乙烯非织造布叠层体耐水性改良不充分等问题,达到抗拉强度优异、低温密封性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132]

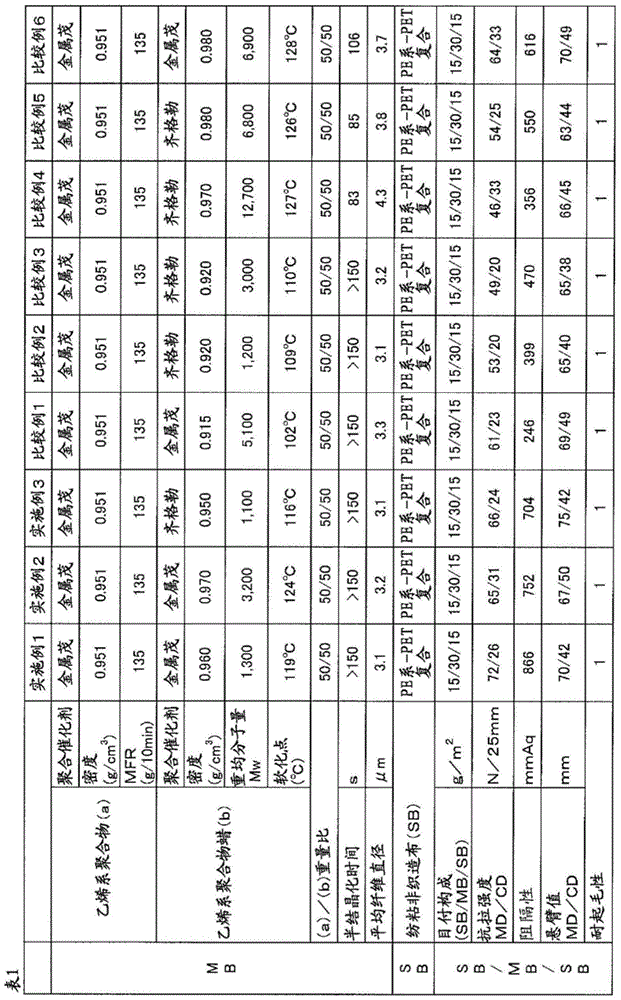

[0133] An ethylene-1-hexene copolymer obtained by a metallocene catalyst [manufactured by Primepolymer Co., Ltd., product name: Evolue H SP50800P, density: 0.951 g / cm 3 , MFR: 135g / 10 minutes] 50 parts by weight, and ethylene polymer wax obtained by metallocene catalyst [Mitsui Chemicals Co., Ltd., product name Excerex10500, density: 0.960g / cm 3 , weight-average molecular weight: 1,300, softening point 119 ° C] 50 parts by weight of the mixture, from the spinneret with 0.4mmφ, 360 holes of the nozzle, the molten resin is discharged at 0.7g / min per single hole, by the melt blown method Melt spinning is performed to form microfibers, which are deposited on the collection surface to produce mesh weight 30g / m 2 Meltblown nonwovens (MB).

[0134]

[0135] As the ethylene-based copolymer constituting the sheath, ethylene-1-butene copolymer [manufactured by Primepolymer Co., Ltd., product name: NEO-ZEX NZ50301, density 0.950 g / cm was used. 3 , MFR (according to ASTM D1...

Embodiment 2

[0139] In place of the ethylene-based polymer wax of the melt-blown nonwoven fabric used in Example 1, an ethylene-based polymer wax obtained by a metallocene catalyst was used [manufactured by Mitsui Chemicals Co., Ltd., product name Excerex 20700, density: 0.970 g / cm 3 , weight average molecular weight: 3,200, softening point: 124°C], using the same manufacturing method as in Example 1, a nonwoven fabric laminate having a three-layer structure was obtained. The physical properties of the obtained nonwoven fabric laminate were measured by the methods described above. The results are shown in Table 1.

Embodiment 3

[0141] Instead of the ethylene-based polymer wax of the melt-blown nonwoven fabric used in Example 1, use an ethylene-based polymer wax obtained by using a Ziegler catalyst [Mitsui Chemicals Co., Ltd., product name Hi-wax100P, density: 0.950g / cm 3 , weight average molecular weight: 1,100, softening point: 116°C], using the same manufacturing method as in Example 1, a nonwoven fabric laminate having a three-layer structure was obtained. The physical properties of the obtained nonwoven fabric laminate were measured by the methods described above. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com