Powder covering and sweeping device during electrostatic powder spraying

A technology of electrostatic powder and cleaning device, which is applied in the direction of spraying device, device for coating liquid on the surface, coating, etc. It can solve the problems that the film cannot be reused and the efficiency is low, and achieve simple and convenient operation, high efficiency and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the multi-layer invention of the present invention will now be described with reference to the accompanying drawings.

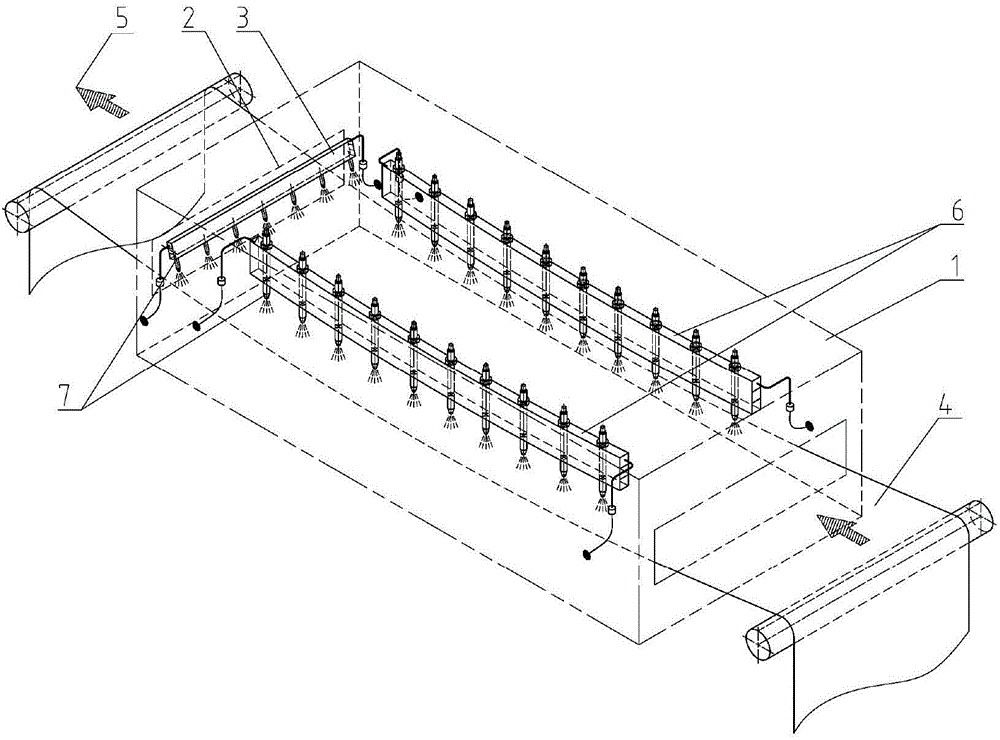

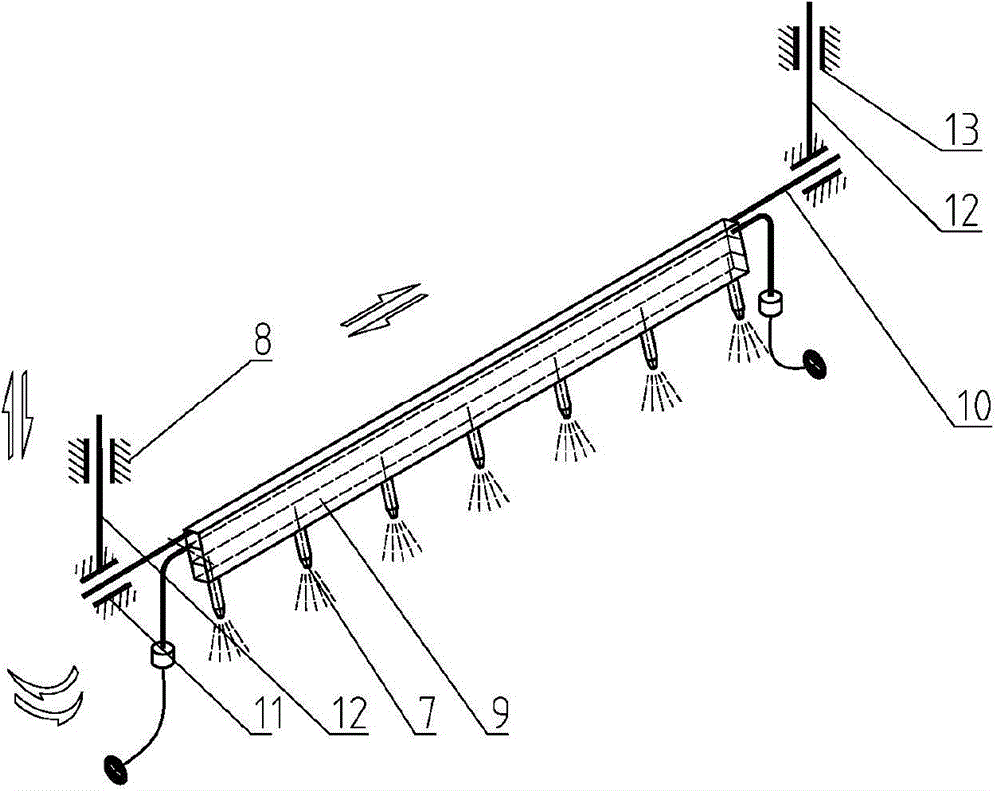

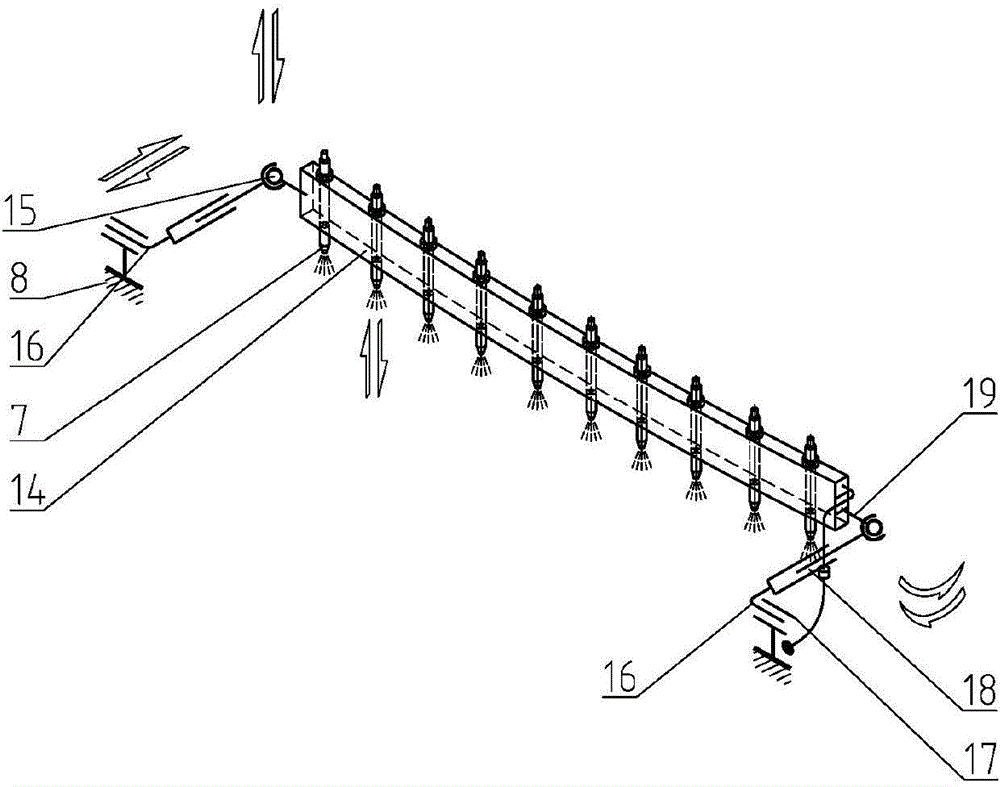

[0030] see figure 1 The powder shielding and cleaning device in electrostatic powder spraying of the present invention includes a powder room 1 with an inlet and an outlet, an end purge device 3 arranged at the outlet 2 in the powder room, and a base material 4 along the sprayed surface. Side air curtain devices 6 are respectively arranged on both sides of the width of the running direction 5 . figure 1 The designed structure is as follows: powder coating is carried out on the bottom of the board, powder shielding and cleaning devices are installed on the top of the board for purging, and the direction of the compressed air nozzle 7 is directed downward. In the same way, when powder coating is carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com