A woodworking lathe with a rotatable spindle box

A woodworking lathe and headstock technology, applied in woodworking lathes, wood processing equipment, manufacturing tools, etc., can solve the problems of not being able to fully meet the needs of use, not being able to realize the rotation function, etc., and achieve good economic and social effects, and is very practical Sex, the effect of short parking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further clarified below in conjunction with specific drawings. This specific embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these modes are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

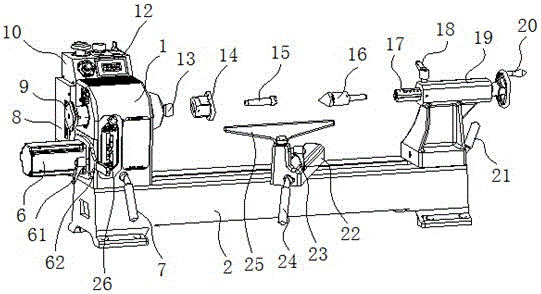

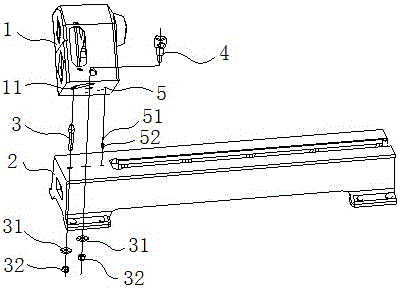

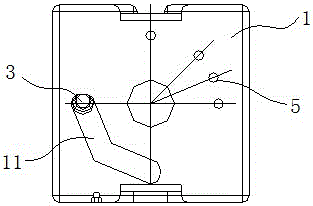

[0020] Such as figure 1 As shown, a woodworking lathe with a rotatable spindle box includes a spindle box 1, a bed 2, a tool rest 25 and a tailstock 19; , The tool rest 25 is located on the bed 2 between the spindle housing 1 and the tailstock 19, wherein both the tool rest 25 and the tailstock 19 can move back and forth on the bed 2 along the guide rails. A motor 6, a spindle box locking handle 7, a driver 8, a spindle handwheel 9, a control button 10, a speed display 12, a box embedded door 26, and a spindle 13 are arranged on the spindle housing 1, and the spindle 13 and the 3" faceplate 14, and used in conjunctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com