Product surface milling device

A milling device and product technology, applied in the direction of positioning device, feeding device, milling machine equipment, etc., can solve the problems of different thickness of black leather, poor universality of fixtures, unfavorable metal reprocessing, etc., to avoid misoperation of workers, realize protection work, The effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make it easier for those skilled in the art to understand the present invention, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings.

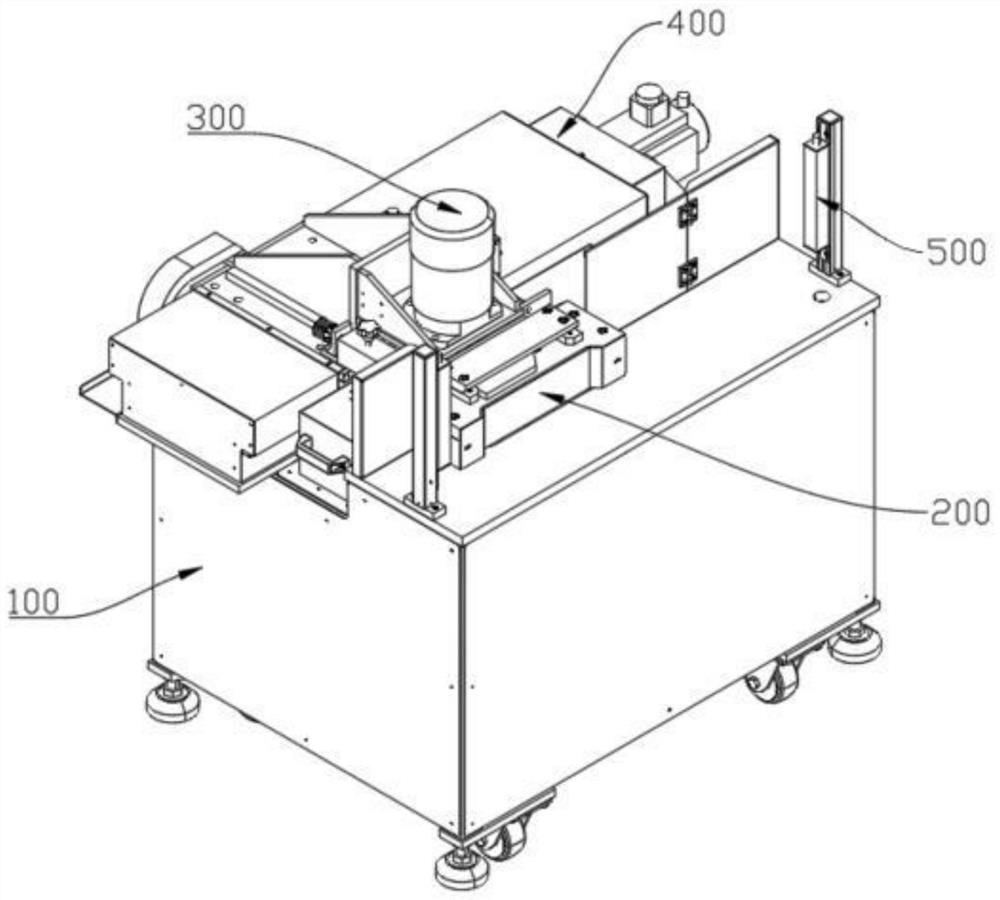

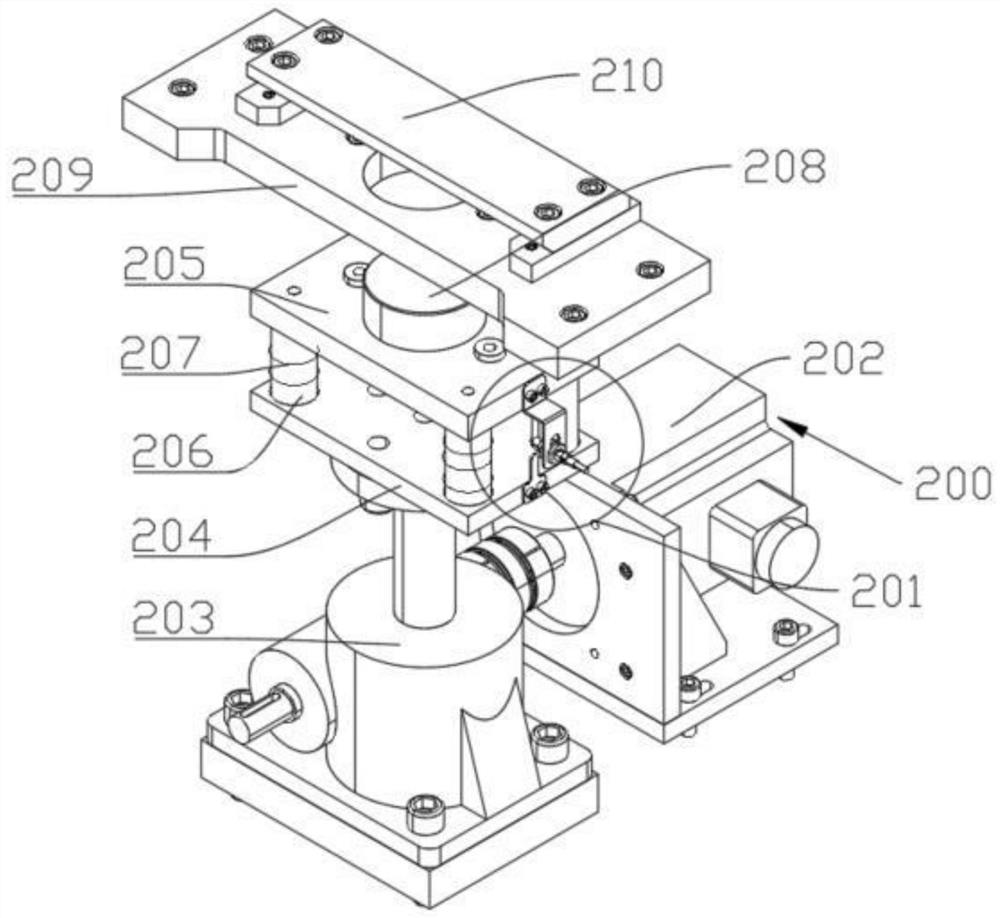

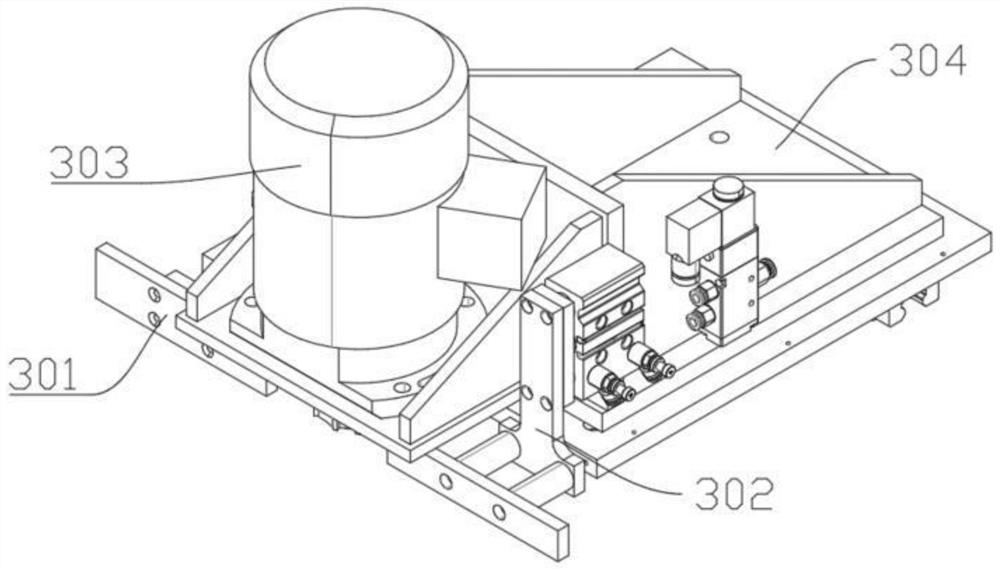

[0033] like Figure 1 to Figure 8 As shown, the present invention provides a product surface milling device, including a frame 100, a product lifting module 200, a cutter head module 300 and a cutter head moving module 400, and the upper side of the frame 100 is provided with the product Lifting module 200, one side of the product lifting module 200 is provided with the cutter head module 300, the cutter head module 300 is fixed on the cutter head moving module 400, and the cutter head moving module 400 is fixed on the upper surface of the frame 100 . By setting the frame 100, the product price increase module, the cutter head module 300 and the cutter head moving module 400 can be installed on the frame 100 to form the whole black leather milling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com