A flexible welding equipment integrating detection and welding

A welding equipment and flexible technology, applied in the field of flexible welding equipment, can solve the problems of occupying workshop space and wasting costs, and achieve the effects of convenient maintenance, low production cost and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

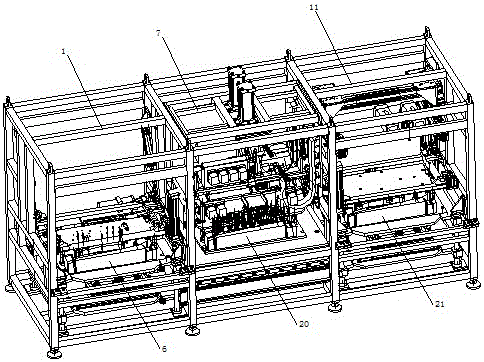

[0019] Such as figure 1 As shown, a flexible welding equipment integrating detection and welding includes three stations, each station is provided with an independent operation unit, and the operation unit includes a workpiece detection station, a hot riveting welding station and Ultrasonic welding station;

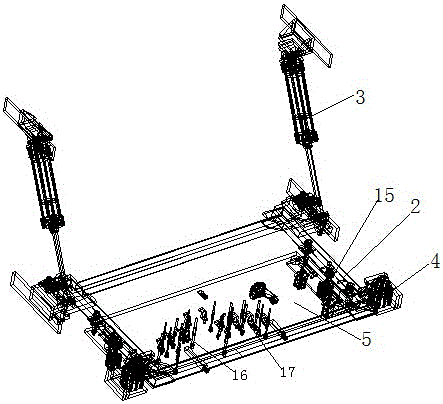

[0020] The workpiece detection station includes a workpiece detection station frame 1, a workpiece inspection tool arranged in the workpiece detection station frame 1, and the workpiece inspection tool includes a detection frame 2, a flipping tool arranged at the rear end of the detection frame 2 Cylinder 3, the clamping cylinder 4 arranged on the left and right sides of the front end of the detection frame 2, the workpiece positioning platform 5 and the workpiece positioning module 6 arranged in the detection frame 2, the workpiece positioning platform lifting cylinder 15 is also set in the detection frame, And the detection switch 16 and the positioning clamping block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com