Assembly line mechanism

An assembly line and waterline technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve problems affecting the quality of parts, affecting work efficiency, and the part number of parts cannot be determined, so as to prevent product mistakes and run smoothly. , the effect of preventing hard impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

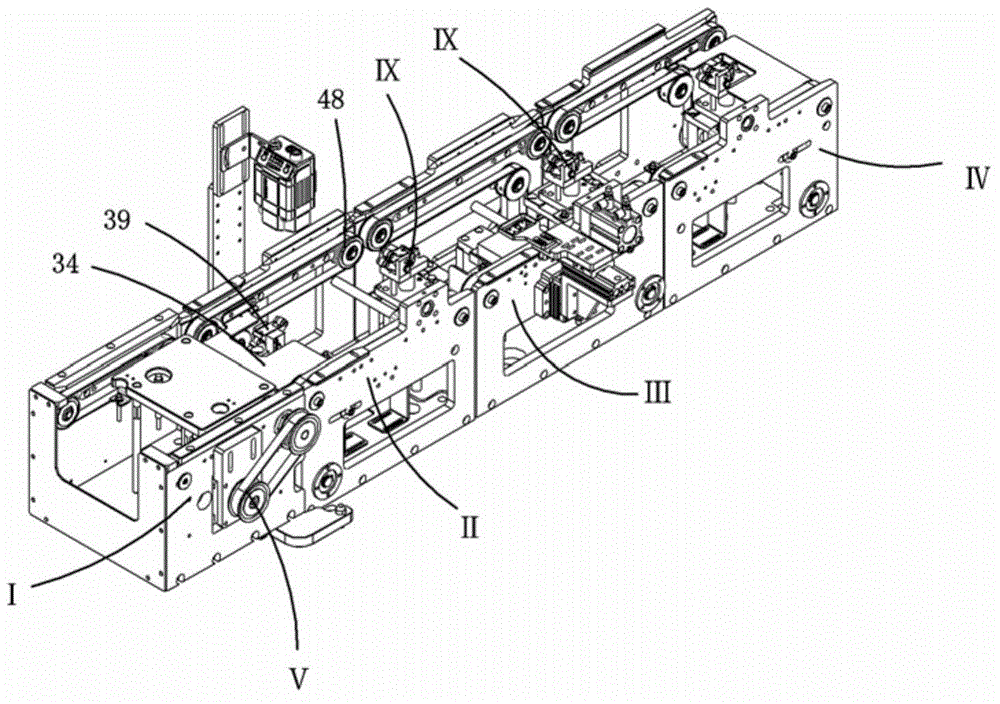

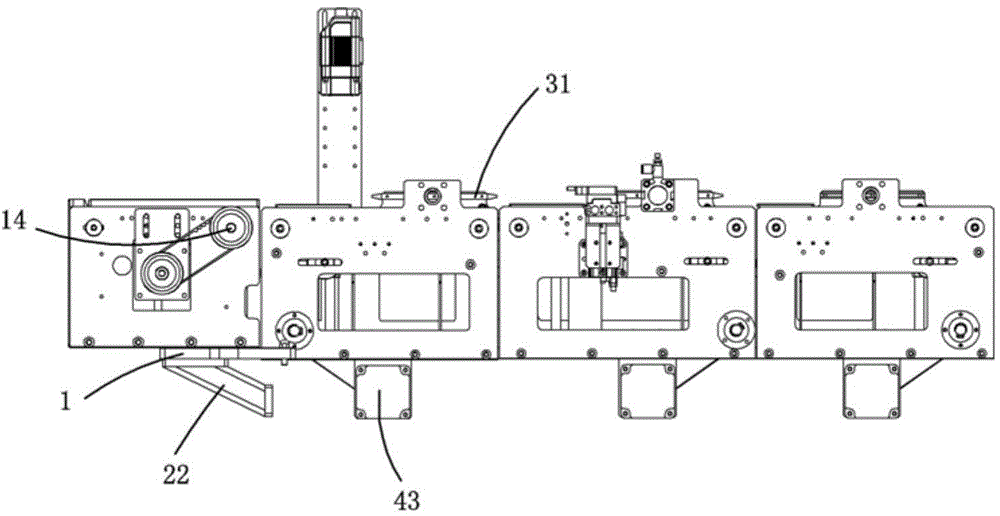

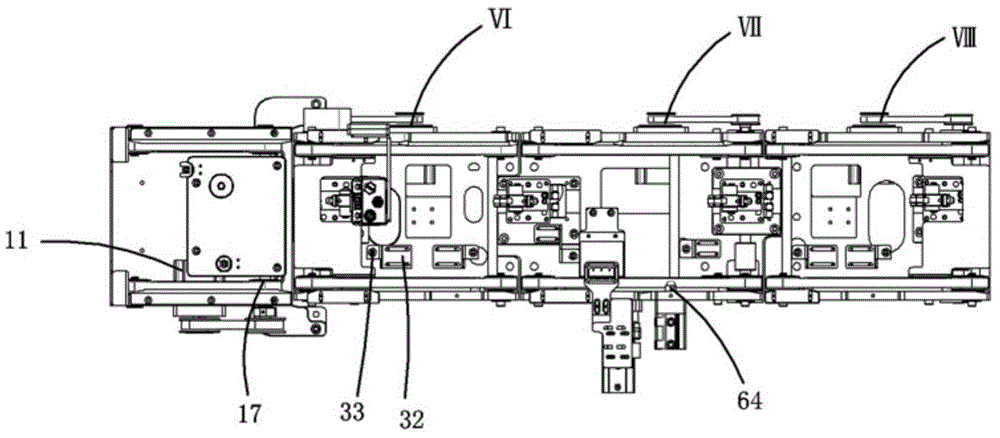

[0036] Examples, see attached Figure 1-9 , an assembly line mechanism, which includes sequentially connected feed assembly line mechanism Ⅰ, first assembly line mechanism Ⅱ, second assembly line mechanism Ⅲ and discharge assembly line mechanism Ⅳ, the feed assembly line mechanism includes a feed installation plate 1, a feed Base plate 2, feed front side plate 3, feed rear side plate 4 and feed drive device V, the feed base plate is installed on the feed installation plate, and the front and rear sides of the feed base plate are respectively equipped with feed The front side panel and the feeding rear side panel, the connection column between the feeding front side panel and the feeding rear side panel is strengthened and fixed to ensure the stability of the whole mechanism; the feeding front side panel and the feeding rear side panel A feed driving device is installed on the top, and a feed pallet 6 is installed on the feed bottom plate through four feed pillars 5, and the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com