A whole line machine and filling and freeze-drying linkage line

A technology of aligning machine and pneumatic sliding table, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of long bottle collection and bottle discharge time, long telescopic stroke of push rod, and low bottle output frequency, so as to reduce the collection and discharge frequency. Bottles and bottle-out time, increase bottle-out frequency, and take up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

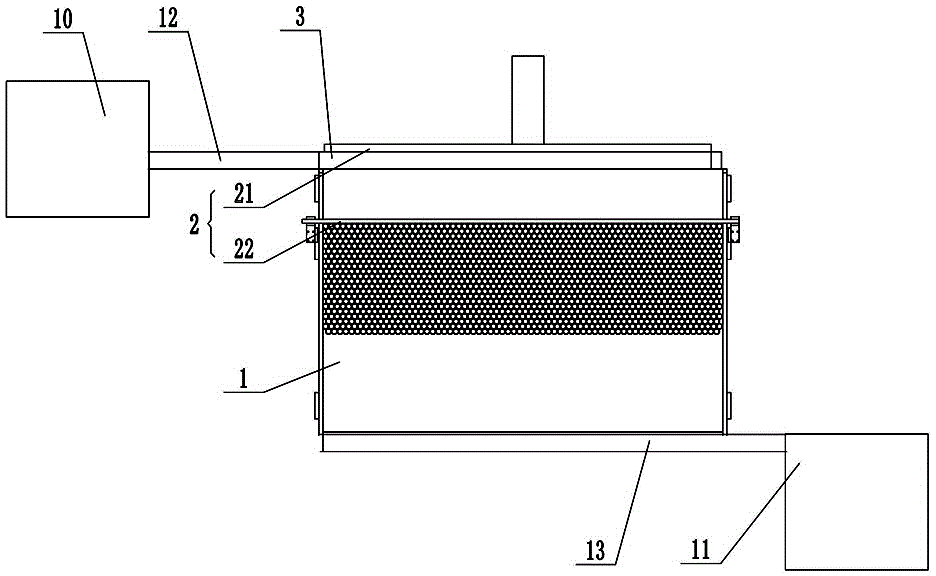

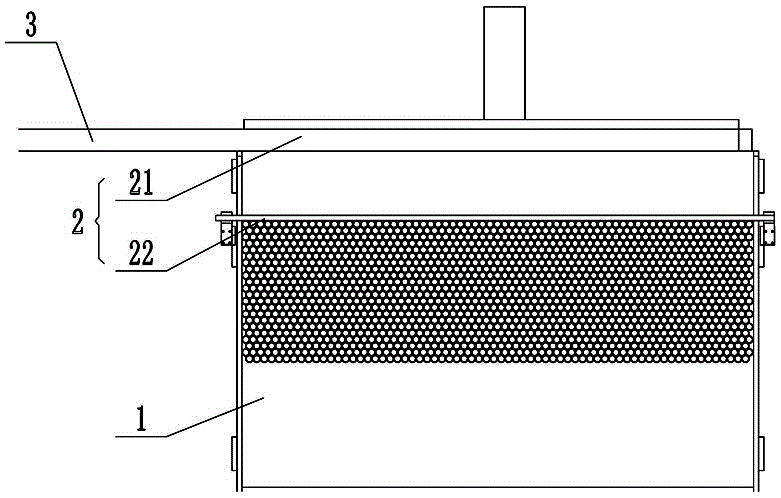

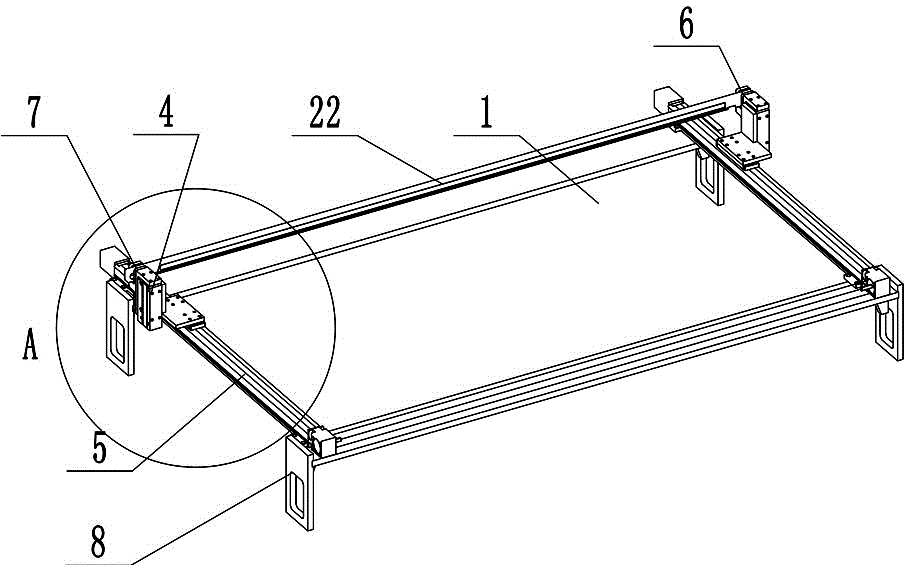

[0025] Such as Figure 2 to Figure 4 As shown, the alignment machine of this embodiment includes a material collecting platform 1, a bottle pushing assembly 2 and a bottle unscrambling channel 3, and the bottle unscrambling channel 3 is used for unscrambling the bottles of the upstream equipment in a single row. The bottle pushing assembly 2 includes a bottle collection push rod 21 and a bottle discharge push rod 22. The bottle collection push rod 21 pushes the bottle body of the bottle unscrambling channel 3 to the material collecting platform 1, and the bottle collection push rod 21 is arranged on the side of the bottle unscrambling channel 3 , the arrangement direction of the bottle collection push rod 21 is parallel to the bottle conveying direction of the unscrambling channel 3; the bottle discharge push rod 22 pushes the multi-row bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com