A Method for Optimal Operation of Isothermal Layer Aerator

A technology for optimizing operation and aerators, applied in chemical instruments and methods, water aeration, sustainable biological treatment, etc., can solve the problems of poor operation effect of isothermal layer aerators and lack of optimized operation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097]The present invention will be described in further detail below in conjunction with the accompanying drawings.

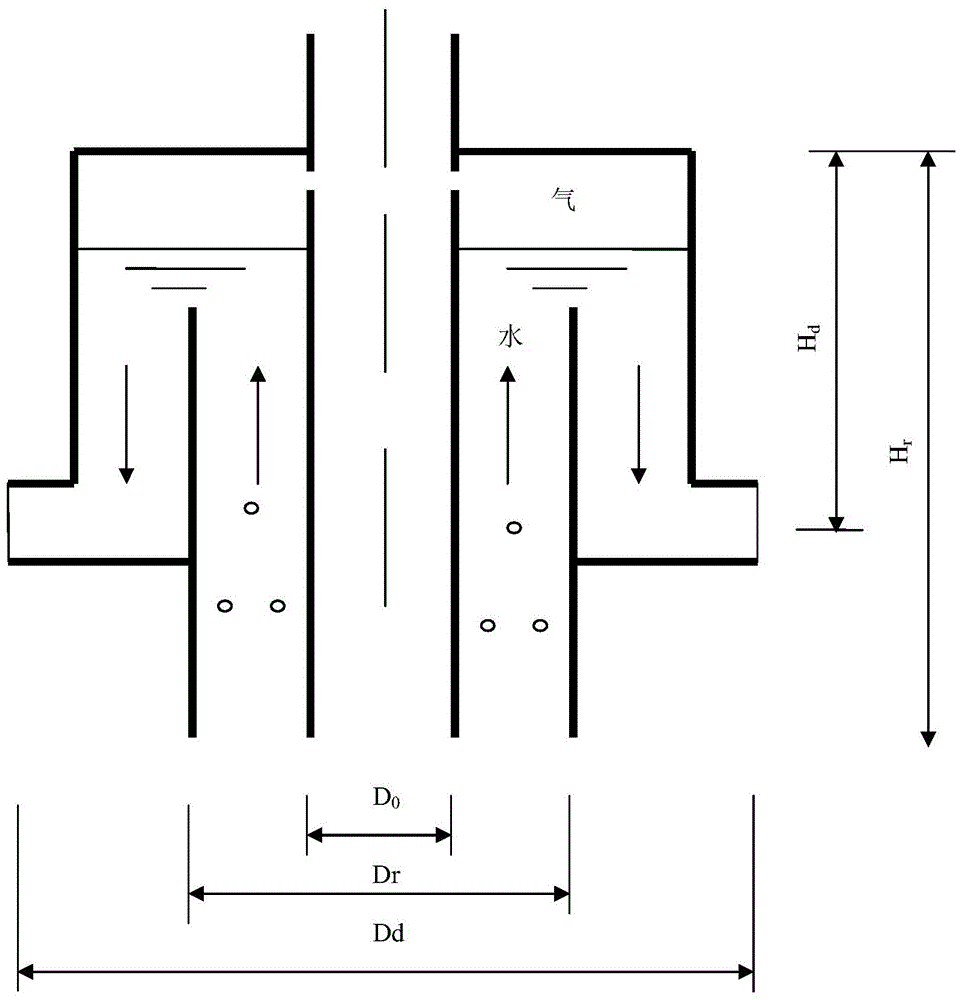

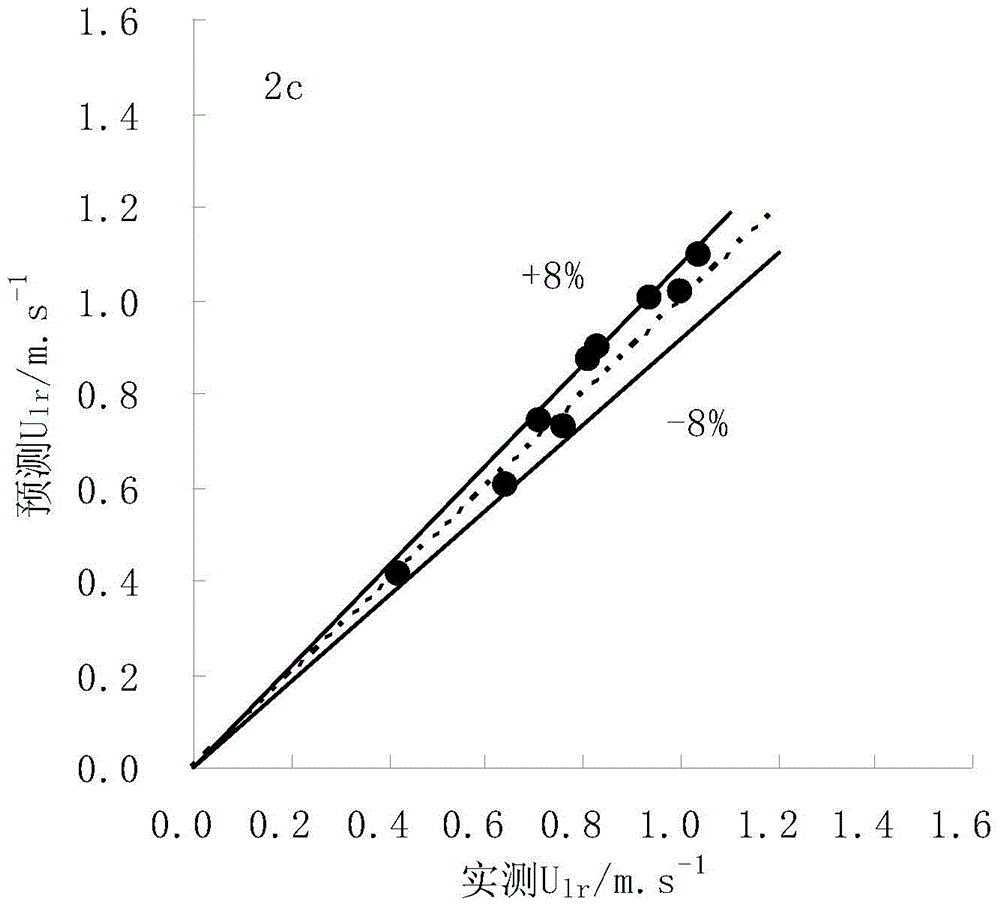

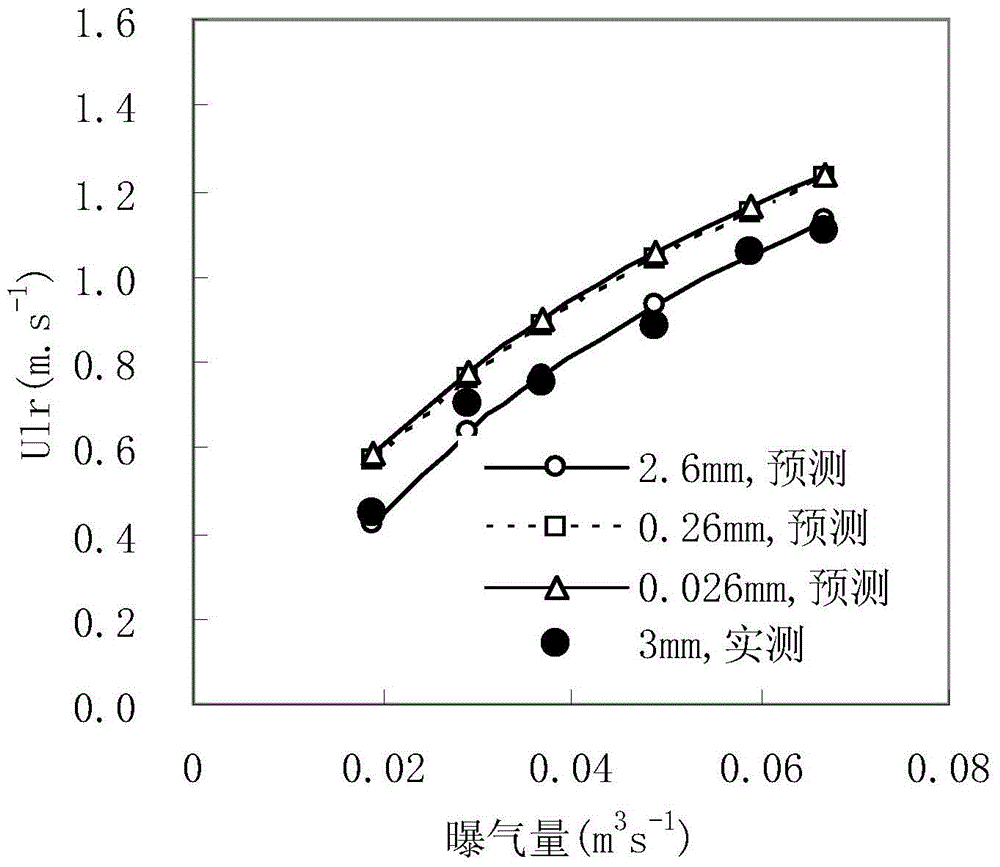

[0098] see figure 1 , a kind of isothermal layer aerator optimization operation method of the present invention, specifically comprises the following contents:

[0099] Establishment and Solution of Oxygenation Kinetic Model

[0100] In the aeration chamber, there are two main oxygen mass transfer processes in the water: one is the bubble-water interface oxygen mass transfer during the bubble rising process, and the other is the air-water interface oxygen mass transfer in the residual air accumulated at the top of the aeration chamber . Since the oxygen mass transfer efficiency of the air-water interface at the top of the aeration chamber is low, the present invention only considers the main oxygen mass transfer process of the air bubble-water interface, thus establishing an isothermal layer aeration and charging process based on the theory of oxygen mass tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com