Integral Orbal oxidation ditch combination type aeration system

A technology of Aubert oxidation ditch and aeration system, applied in the field of integrated Auber oxidation ditch combined aeration system, can solve the problems of inconvenient management and maintenance, complicated equipment, and small adjustment range of oxygen demand, and achieve improvement Sewage treatment capacity, avoid waste of energy, good effect of oxygenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

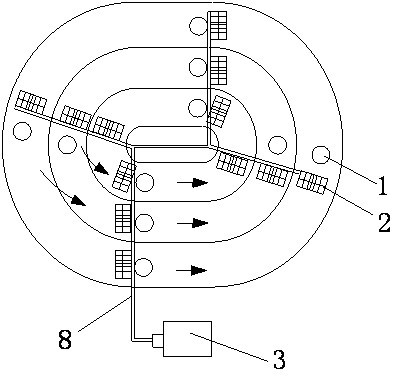

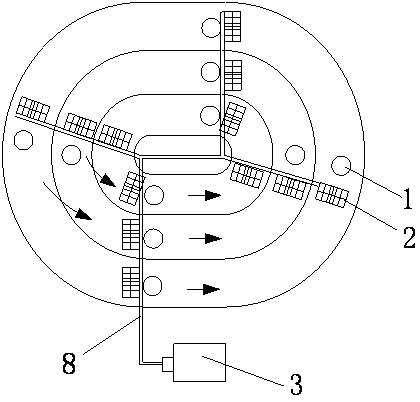

Embodiment 1

[0019] Example 1: Referring to Figure 1, the integrated Aubert oxidation ditch combined aeration system is installed in a three-channel Aubert oxidation ditch, and the flow state between the channels is plug-flow, which includes Ten surface push flow aerators 1 for sewage push flow and aeration and twelve aeration row devices 2 installed on the bottom; four aeration row devices 2 are evenly installed in the three channels, A surface push-flow aerator 1 is installed in front of the aeration row device 2 installed in the middle ditch, and a surface push-flow aerator is installed in front of the two aeration row devices 2 separated in the inner ditch. , each aeration row device 2 is connected in parallel on the main pipe 8 pipeline. In this implementation, the fan 3 is a Roots blower, a combination of blast aeration and surface push flow aerator 1, the fan 3 is used for centralized air supply, the surface push flow aerator 1 is used for sewage push flow, and each aeration row dev...

Embodiment 2

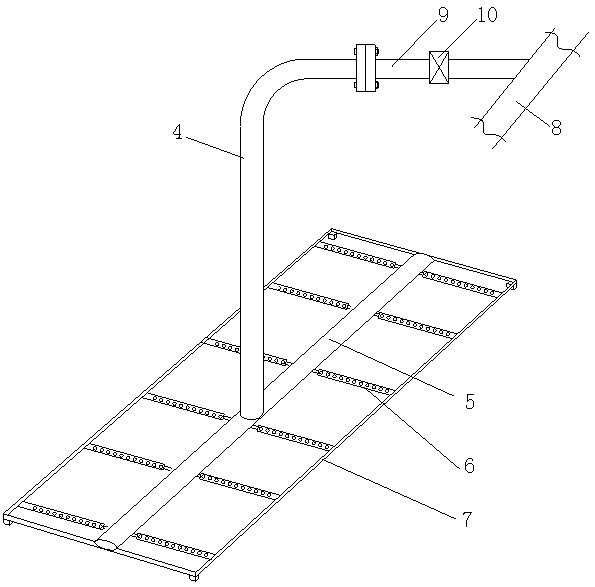

[0023] Embodiment 2: On the basis of Embodiment 1, a support frame 7 for fixing the aeration pipe 6 is also included. In order to enhance the stability of the aeration row, the support frame 7 is a rectangular frame welded by steel. The weight of the entire aeration row device can be increased so that it can be immersed in the pool with the help of natural gravity, and the aeration tube will not float up due to low density or shake due to the inflated blast of the surface push flow aerator, which improves the aeration device. Working performance; at the same time, the two ends of the aeration pipe 6 are respectively fixed between the support frame 7 and the air supply branch pipe 5, which is more stable and impact-resistant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com