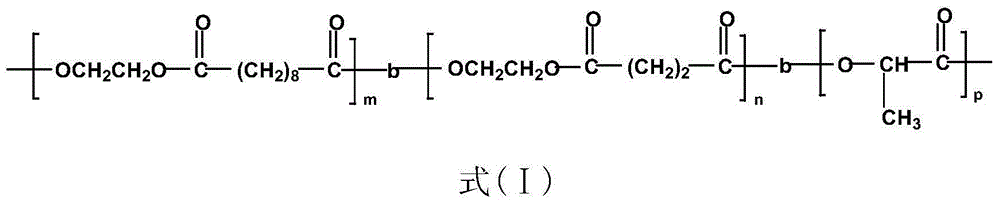

Polylactic acid ternary block copolyester and preparation method thereof

A ternary block and polylactic acid technology, applied in the field of modified biodegradable polyester, can solve problems such as unsatisfactory synergistic effect, complex preparation process, and difficult industrial realization, so as to maintain biodegradability and wide Prospects for development and effects of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

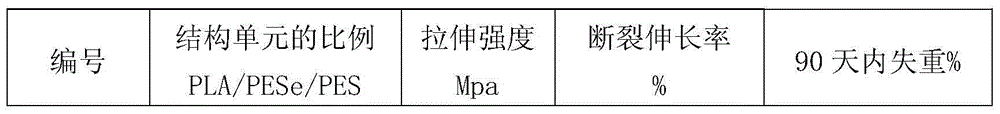

Examples

Embodiment 1

[0049] Add LLA to the reactor, add 0.2 parts by weight of stannous octoate (relative to 100 parts by weight of LLA), purging with high-purity nitrogen for 5 hours, and place the reaction bottle at 175 After 5 hours of reaction, the reaction bottle was cooled and opened, and the mixture was dissolved in chloroform and precipitated in anhydrous methanol. Polylactic acid prepolymer (PLA) was obtained after vacuum drying. The number average molecular weight measured by GPC was 30,000 g / mol, and the molecular weight distribution was 1.8.

[0050] Add sebacic acid and ethylene glycol into the there-necked flask at a molar ratio of 1:1.3, then add 0.1 parts by weight (relative to 100 parts by weight of sebacic acid and ethylene glycol) of tetrabutyl titanate, and then Under a nitrogen atmosphere, the temperature was gradually raised to 180° C., and the reaction was carried out for 2 hours until no small molecular fractions were evaporated; then, the obtained reaction product was in...

Embodiment 2

[0054] The polylactic acid triblock copolyester is prepared according to the method of Example 1, the difference is that the addition of the prepolymer is 112 grams of PLA, 70 grams of PESe, 98 grams of PES, 1.46 grams of HDI is added, and the chain segment structure in the product The weight ratio of the units PLA, PESe and PES is 40 / 25 / 35.

Embodiment 3

[0056] The method for preparing polylactic acid triblock copolyester according to embodiment 1, difference is, the addition of prepolymer is PLA 81 grams, PESe 81 grams, PES 108 grams, add HDI 1.42 grams, the chain segment structure in the product The weight ratio of the units PLA, PESe and PES is 30 / 30 / 40.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap