Installation and transportation vehicle for efficient safe mine hydraulic support

A hydraulic support, safe technology, applied in mine roof support, underground transportation, transportation and packaging, etc., can solve the problems of bulkiness, large space occupation and unsafety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

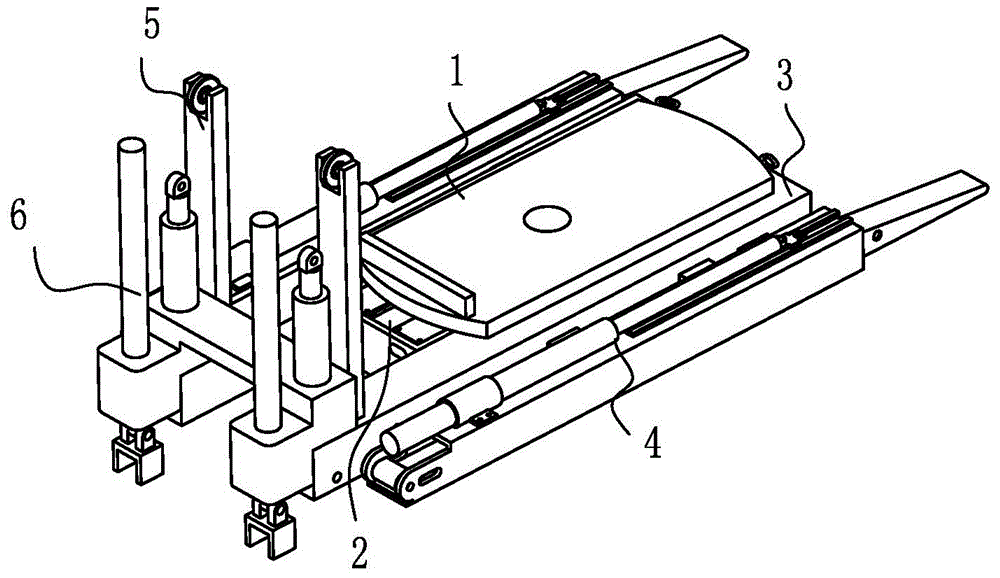

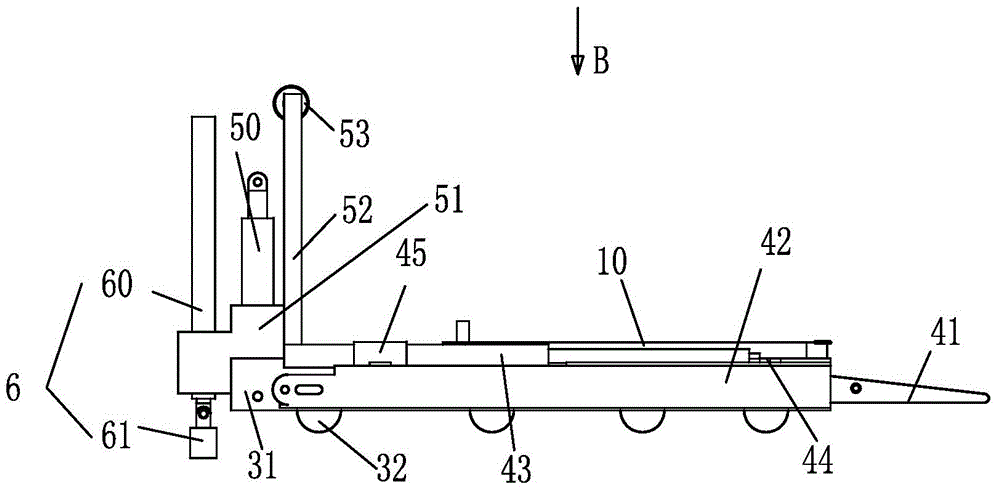

[0034] to combine Figure 1-2 , Figure 5 As shown, the high-efficiency and safe mining hydraulic support installation transport vehicle of the present invention includes a rotating assembly 1 , a bearing assembly 2 , a load beam assembly 3 , a push-pull transition assembly 4 , an anti-fall assembly 5 , and a rear tilt assembly 6 .

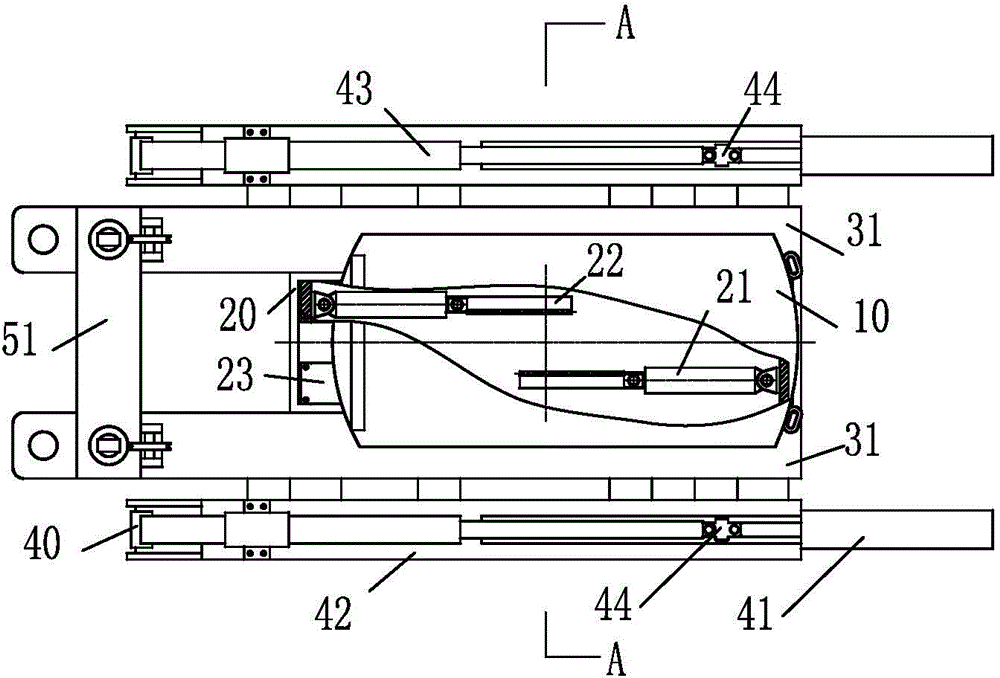

[0035] to combine Figure 4 , Image 6 As shown, the rotating assembly 1 includes a rotating plate 10, a rotating shaft 12, a rotating gear 13, a rotating support plate 14, and a thrust ball bearing 15. The upper end of the rotating shaft 12 is fixed on the center of the rotating plate 10, and on the rear side of the rotating plate 10 The surface is provided with transverse stop beams 16 . When the hydraulic support is transported, the stop beam 16 can prevent the hydraulic support from sliding on the rotating plate 10 to a certain extent.

[0036] The rotating support plate 14 and the rotating gear 13 are set in the middle of the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com