Display module

A display module and display panel technology, which is applied to instruments, identification devices, etc., can solve the problem of uneven screen display of display modules, reduce the probability of uneven screen display, simple structure, and enhance structural stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

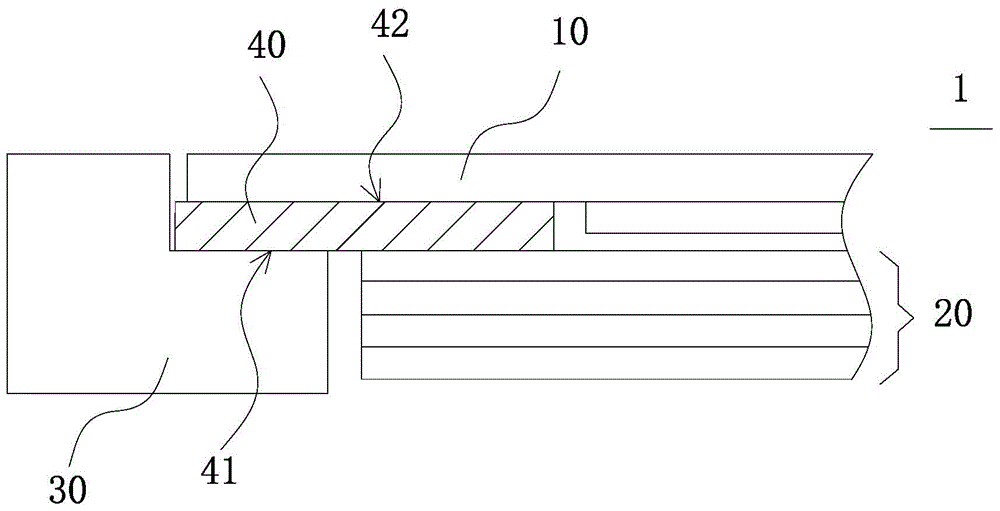

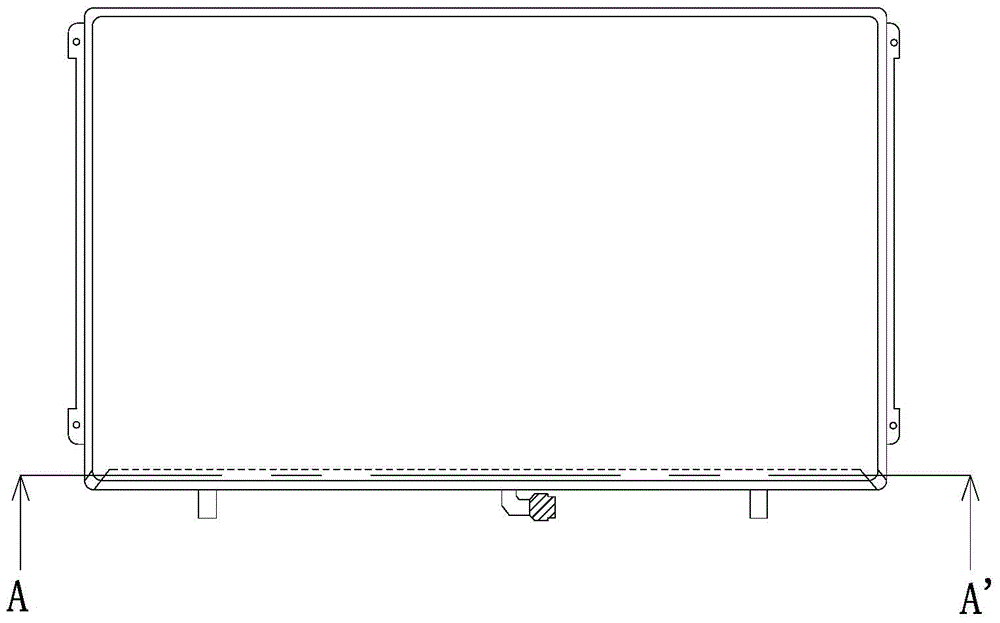

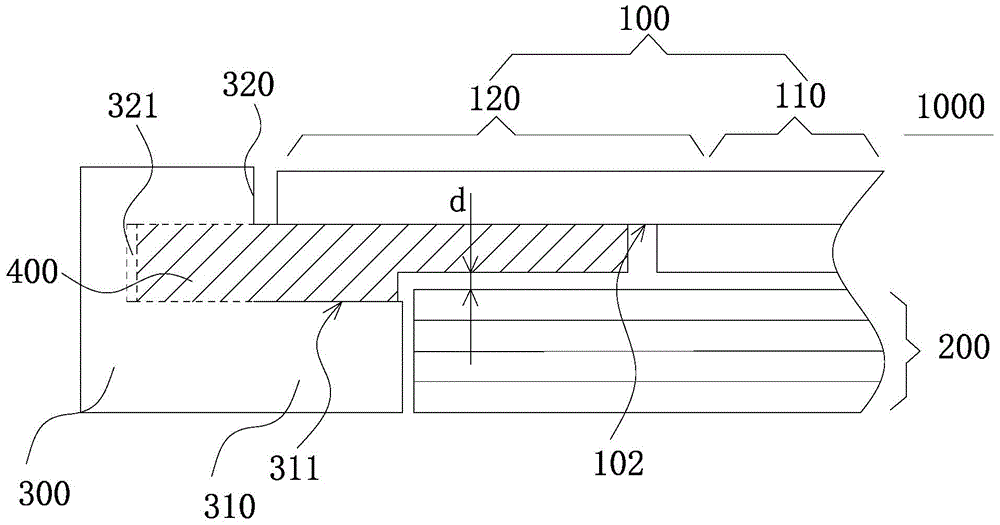

[0029] Please refer to figure 2 , Figure 3A , Figure 3B and Figure 3C , figure 2 It is a top view of the display module of the present invention; Figure 3A for figure 2 Partial sectional view along line AA'; Figure 3B for Figure 3A Partial schematic diagram of the middle frame; Figure 3C for Figure 3A Schematic diagram of the adhesive layer. The display module 1000 includes a display panel 100 , an optical film 200 , a frame 300 and an adhesive layer 400 .

[0030] The frame body 300 has a carrying portion 310 and a side wall 320 protruding from the carrying portion 310. The carrying portion 310 has a carrying surface 311. The side wall 320 cooperates with the carrying surface 311 to form a first accommodating space 340 for accommodating the display panel 100. The carrying portion 310 forms a second accommodating space 350 for accommodating the optical film 200 , and at least one slot 321 is formed on the side wall 320 .

[0031] The adhesive layer 400 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com