Optical device

A technology for optical devices and optical components, which is applied in the directions of optics, electromechanical devices, projection devices, etc., can solve the problems of changing the shape, and it is difficult to eliminate the reduction of the curvature of the central part and the curvature of the central part.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

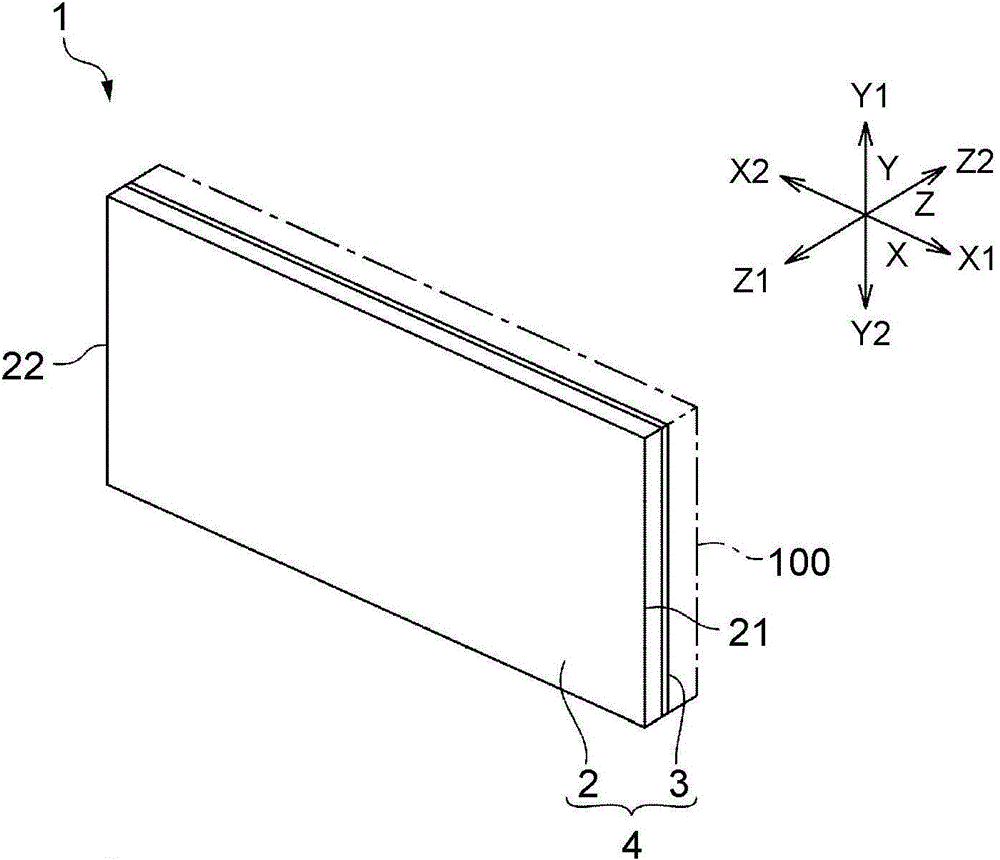

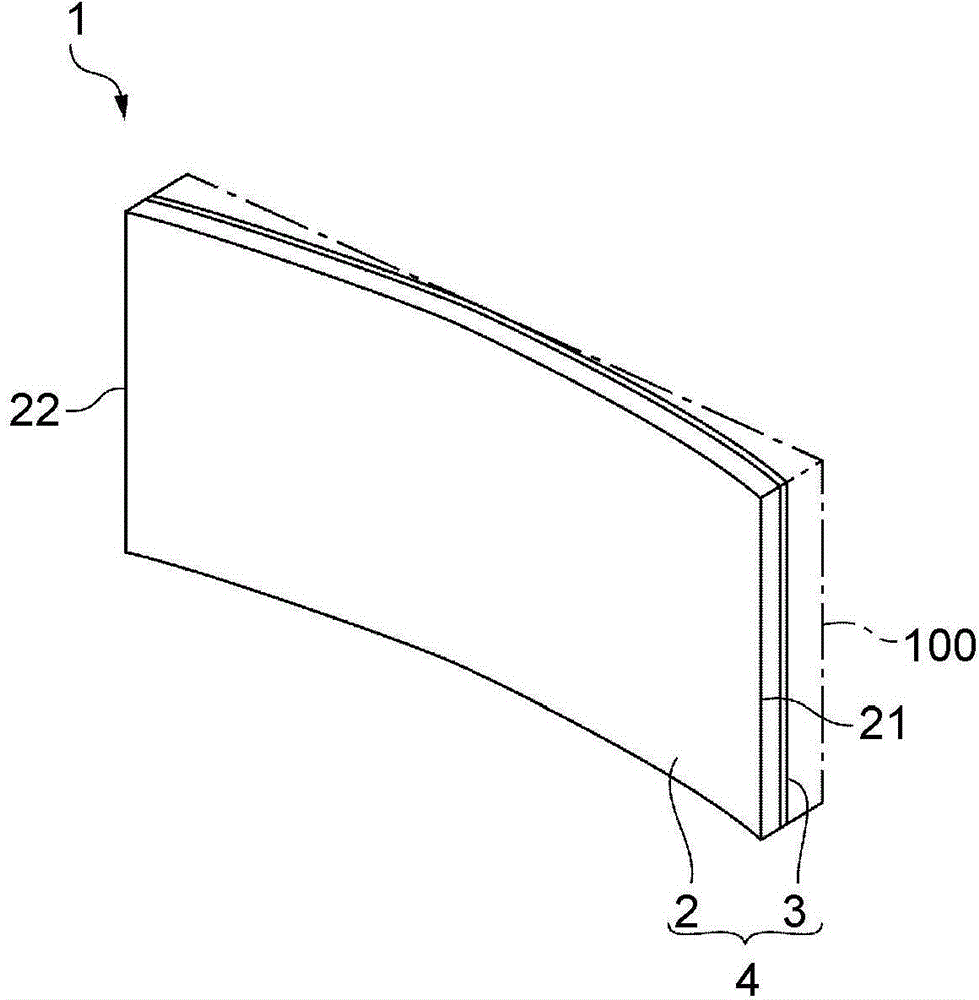

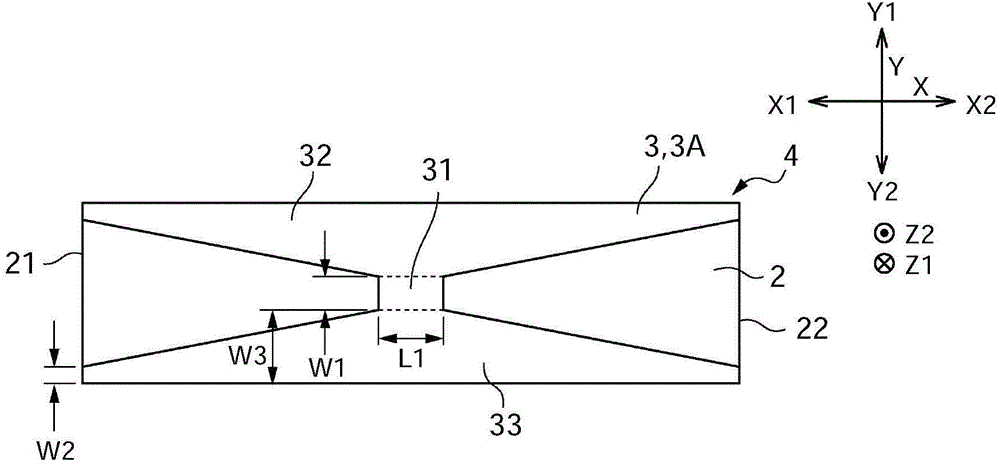

Embodiment 1

[0084] The backside of the optic 2 is bonded by Figure 3(a) to Figure 3(c) The reinforced part 3B is formed of zinc steel sheet as shown. The bending method is as described later with reference to Figure 15(a), Figure 16(a), Figure 16(b) and Figure 17(a), Figure 17(b) along the X direction (first direction) The way the load is applied.

Embodiment 2

[0086] The backside of the optic 2 is bonded by Figure 2(a) to Figure 2(c) The reinforced member 3A is formed of zinc steel sheet as shown. The bending method is as described later with reference to Figure 15(a), Figure 16(a), Figure 16(b) and Figure 17(a), Figure 17(b) along the X direction (first direction) The way the load is applied.

Embodiment 3

[0088] The back plate 9 formed by the quadrangular zinc steel plate is bonded to the back of the optical part 2 (refer to Figure 19(a) to Figure 19(c) ), and bonded at the back of the back plate 9 by Figure 2(a) to Figure 2(c) The reinforced member 3A is formed of zinc steel sheet as shown. The bending method is as described later with reference to Figure 15(a), Figure 16(a), Figure 16(b) and Figure 17(a), Figure 17(b) along the X direction (first direction) The way the load is applied.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com