Material ejection mechanism

A material and material channel technology, applied in the field of material injection mechanism, can solve problems such as complex structure, lower production efficiency, and difficulty in realizing one-time material positioning of materials, so as to simplify the molding process, improve production efficiency, and simplify the assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

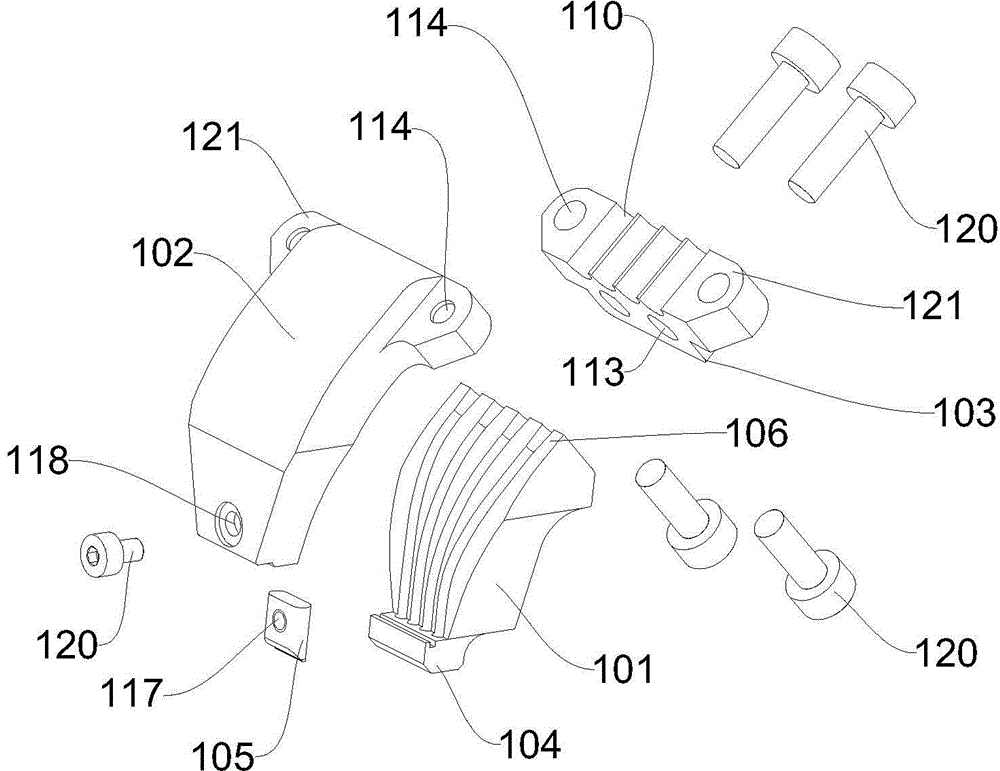

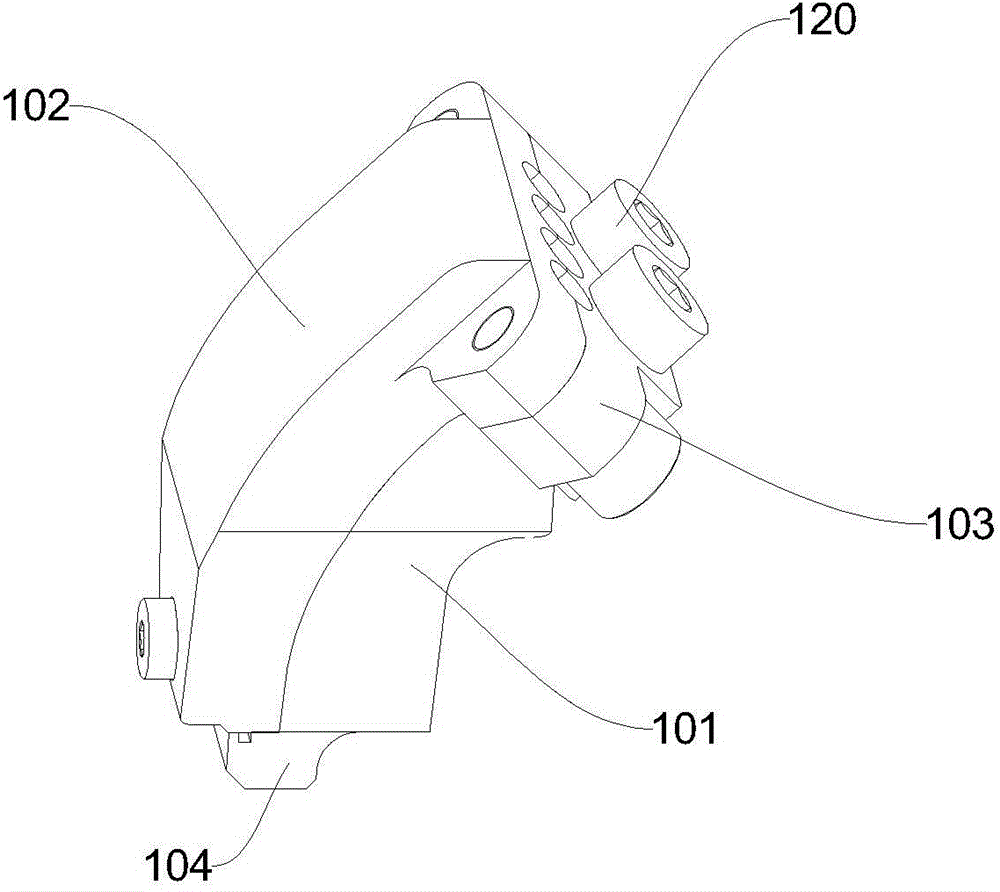

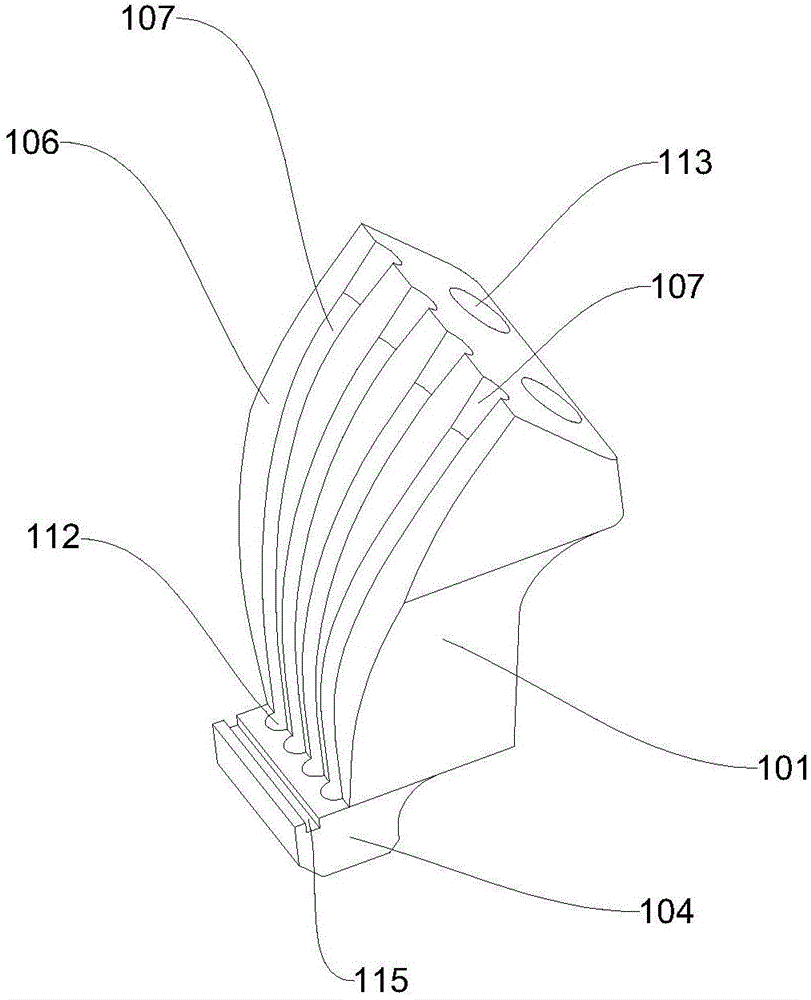

[0053] figure 1 It is an exploded view of the material injection mechanism in Embodiment 1 of the present invention, figure 2 is a schematic structural view of the material injection mechanism in Embodiment 1 of the present invention, image 3 It is a structural schematic diagram of the injection chamber in Embodiment 1 of the present invention, Figure 4 It is a perspective view of the injection chamber in Embodiment 1 of the present invention, Figure 5 is along Figure 4 A sectional view along line A-A, Figure 6 It is a structural schematic diagram of the docking bin in Embodiment 1 of the present invention, Figure 7 It is a perspective view of the docking bin in Embodiment 1 of the present invention, Figure 8 yes Figure 7 B direction view, Figure 9 It is a perspective view of the connector in Embodiment 1 of the present invention. Such as Figure 1 to Figure 9 As shown, Embodiment 1 of the present invention discloses a material injection mechanism, which inc...

Embodiment 2

[0064] Figure 10 It is the explosion diagram of the material injection mechanism in the second embodiment of the present invention, Figure 11 is a schematic structural view of the material injection mechanism in Embodiment 2 of the present invention, Figure 12 It is a perspective view of the injection chamber in Embodiment 2 of the present invention, Figure 13 is along Figure 12 A sectional view along line C-C, Figure 14 is a schematic structural diagram of the docking bin in Embodiment 2 of the present invention, Figure 15 It is a perspective view of the docking bin in Embodiment 2 of the present invention, Figure 16 yes Figure 15 D direction view, Figure 17 It is a perspective view of the connector in Embodiment 2 of the present invention. Such as Figure 10 to Figure 17 As shown, Embodiment 2 of the present invention discloses a material injection mechanism, which includes a conduit fixing part, a material channel part and an injection head connected in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com