Liquid pumping method from container

A container and liquid technology, which is applied to table utensils, home utensils, table utensils, etc., can solve problems such as laboriousness, reduced air pressure, and difficulty in absorbing clean liquids, and achieve smooth liquid absorption, high efficiency, and avoid pressure differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

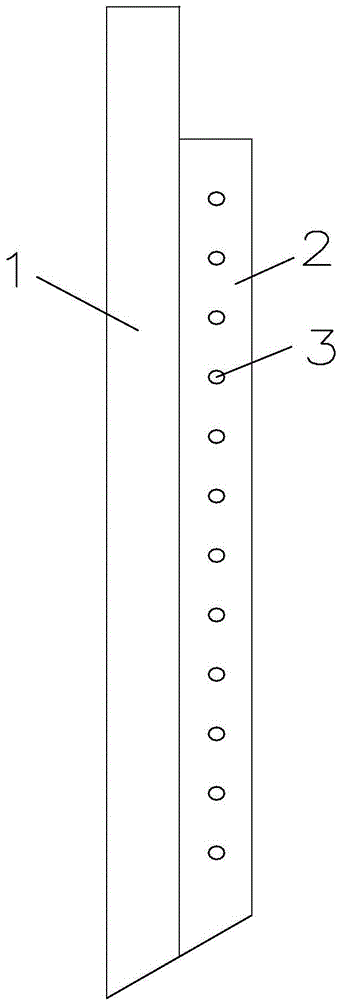

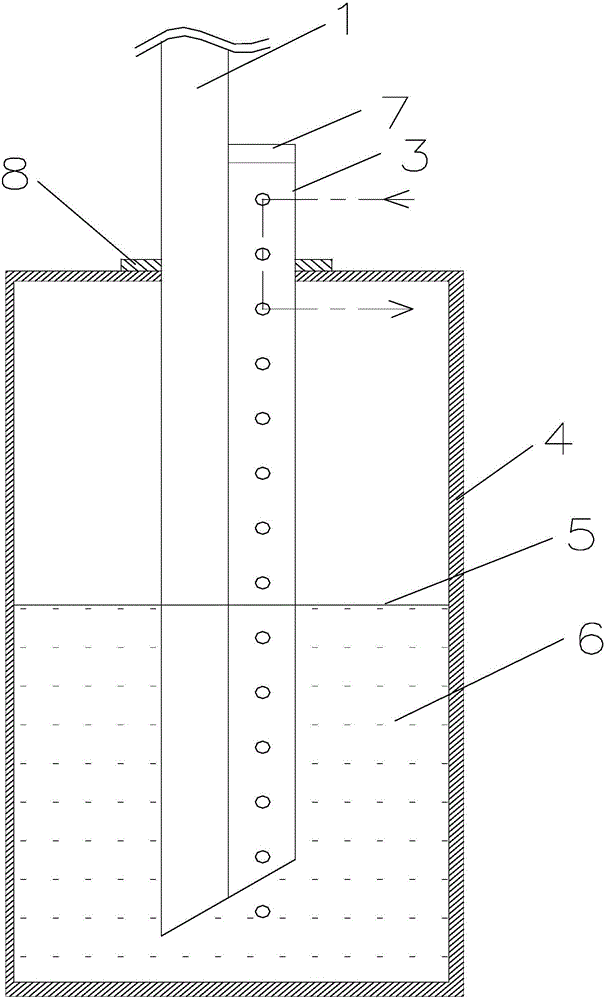

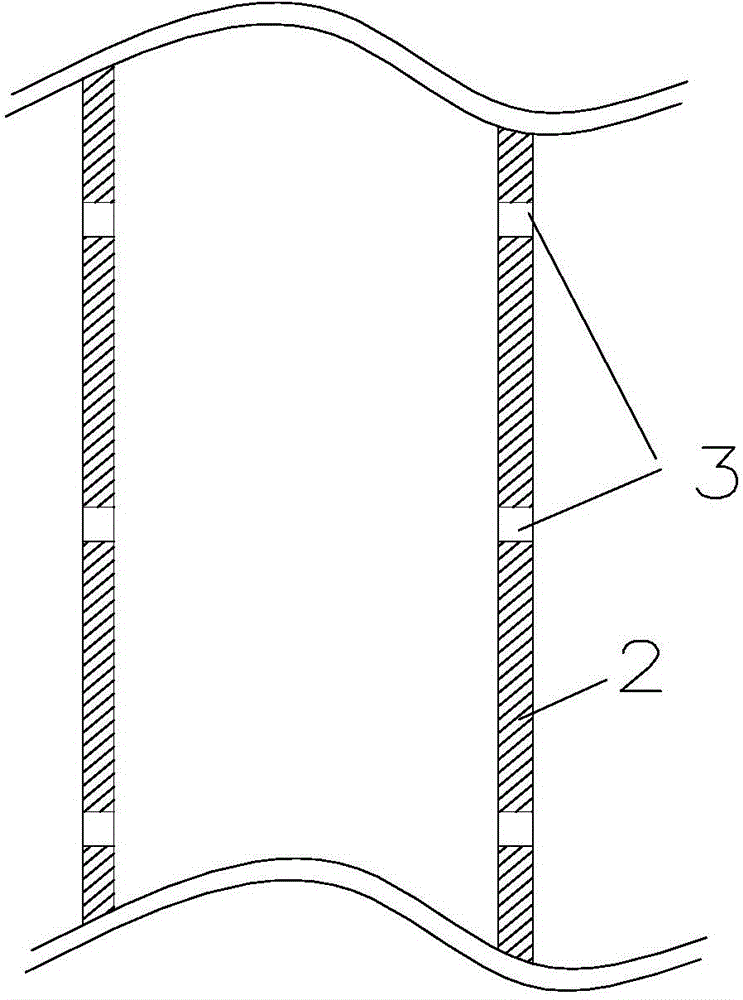

[0040] Embodiment 1: as Figure 1-3 , a method for sucking liquid from a container, the container is an oil barrel; a compound anti-blocking suction pipe is inserted in the through hole of the top cover of the container 4, and the lower end of the compound anti-blocking suction pipe goes deep into the container Below the liquid level, the composite anti-blocking suction pipe includes a main pipe 1 and a secondary pipe 2 connected side by side; the wall of the secondary pipe is provided with a plurality of ventilation holes 3 along the axial direction of the secondary pipe; At least one vent hole is provided between the top cover and the first vent hole, and at least one vent hole is provided between the top cover and the secondary pipe nozzle, which is recorded as the second vent hole; The air inside and outside the container can be communicated through the first air hole and the second air hole, so that the liquid can be sucked out of the container more conveniently through t...

Embodiment 2

[0050] Embodiment 2: as figure 1 , 3-5; a method for sucking liquid from the container, the through hole of the top cover of the container 4 is inserted with a composite anti-blocking suction pipe, and the lower end of the composite anti-blocking suction pipe goes deep into the container Below the liquid surface, the composite anti-blocking suction pipe includes a main pipe 1 and a secondary pipe 2 connected side by side; the wall of the secondary pipe is provided with a plurality of ventilation holes 3 along the axial direction of the secondary pipe; At least one vent hole is provided between the top cover, which is referred to as the first vent hole, and at least one vent hole is provided between the top cover and the secondary pipe nozzle, which is recorded as the second vent hole; The first ventilation hole and the second ventilation hole can communicate the air inside and outside the container, so that the liquid can be sucked out of the container more conveniently throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com