Low-temperature disc mill

A disc grinding and low-temperature technology, applied in cocoa, grain processing, food science, etc., can solve the problems of speeding up the feeding efficiency, achieve the effect of increasing the grinding effect, complete the refining effect, and prolong the length of the grinding space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

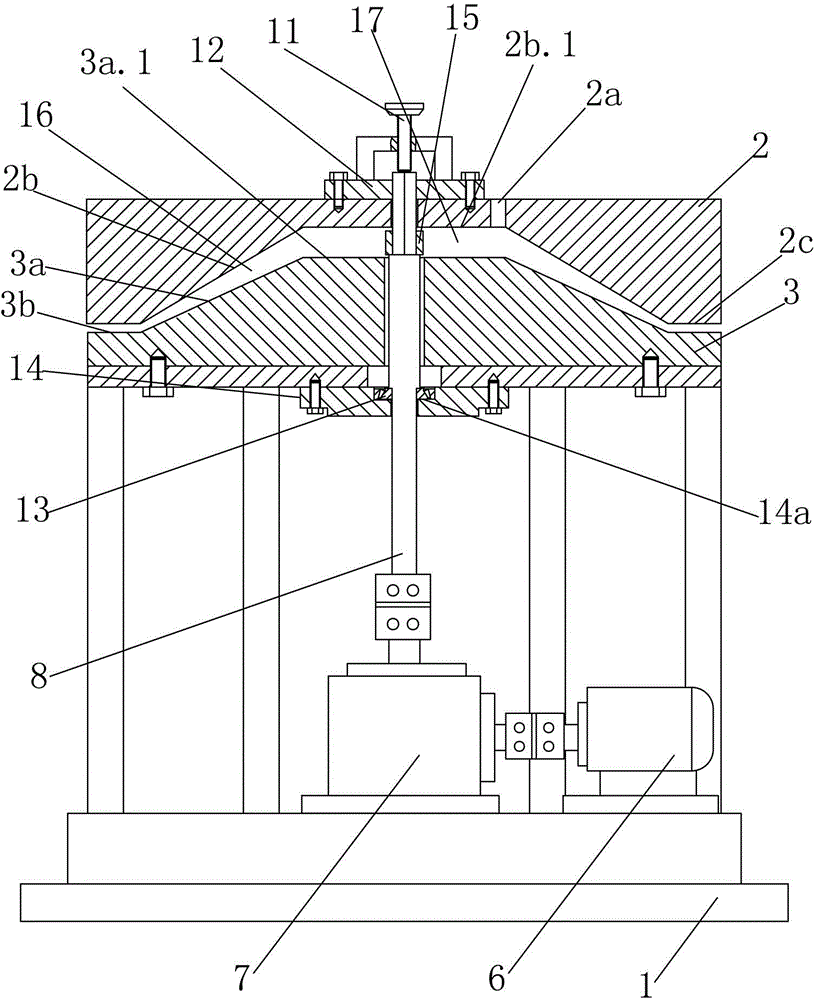

[0012] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

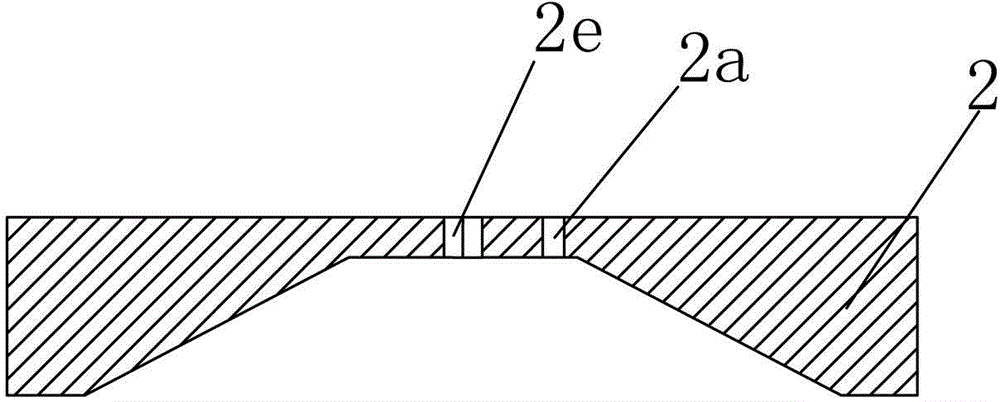

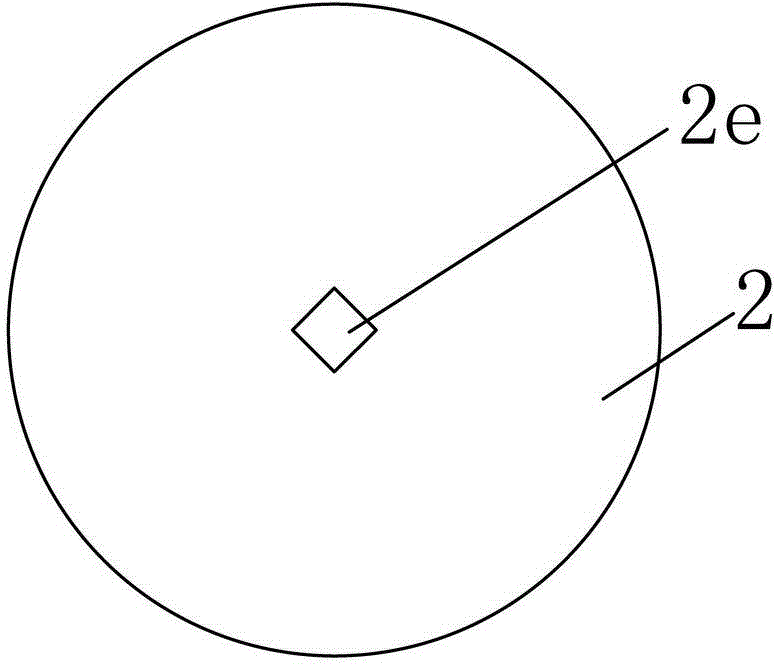

[0013] Such as Figure 1 to Figure 4 As shown, a low-temperature disc mill includes a frame body 1, an upper disc 2 and a lower disc 3, the upper disc 2 and the lower disc 3 are installed oppositely, and the middle part of the lower disc 3 protrudes to form a conical boss 3a with the small end facing upwards The bottom of the boss 3a extends horizontally to form an annular first plane 3b placed on the lower grinding disc 3; the lower end of the upper grinding disc 2 is provided with a concave, conical concave platform 2b that is opposite and matched with the boss 3a. There is a gap between the conical surfaces on the platform 3a and the concave platform 2b, and a wedge-shaped pre-grinding cavity 16 with a large upper diameter and a smaller lower diameter is formed between the two conical surfaces, and an upper grinding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com