Full-automatic drawing machine

A drawing machine, fully automatic technology, applied in the field of machine tools, can solve the problems of backward intelligent drawing machine, poor drawing operation stability, high production cost, avoid equipment derailment, increase workpiece utilization rate, and improve drawing The effect of production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Further explain below in conjunction with accompanying drawing:

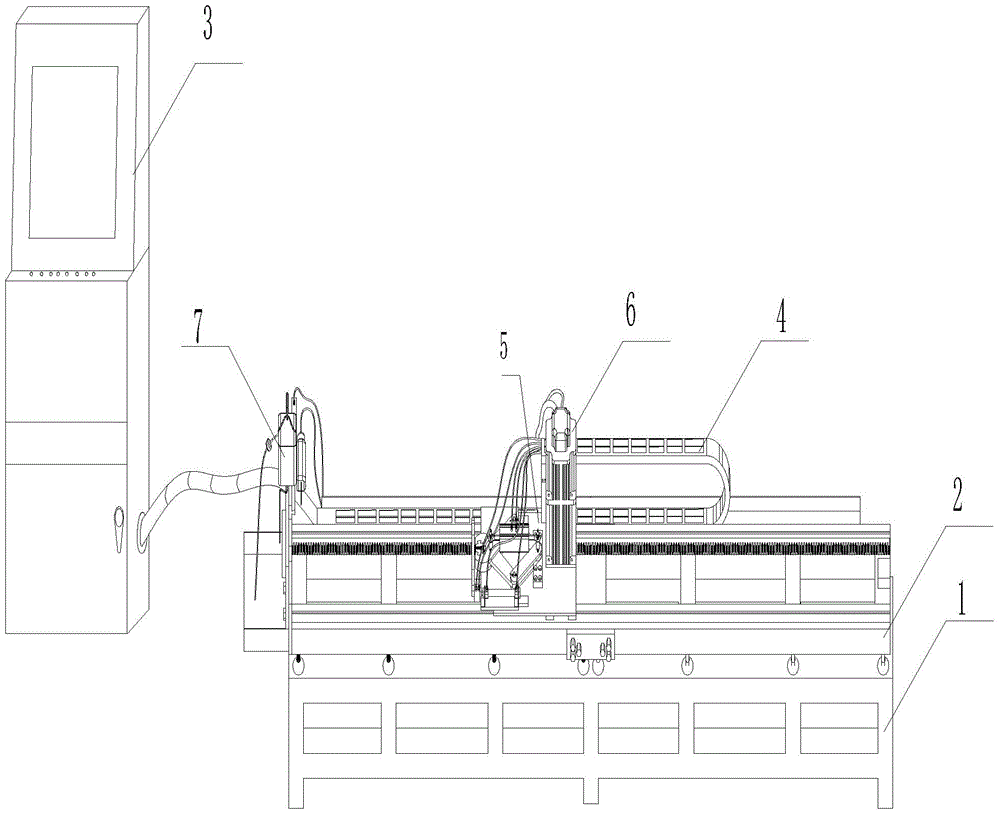

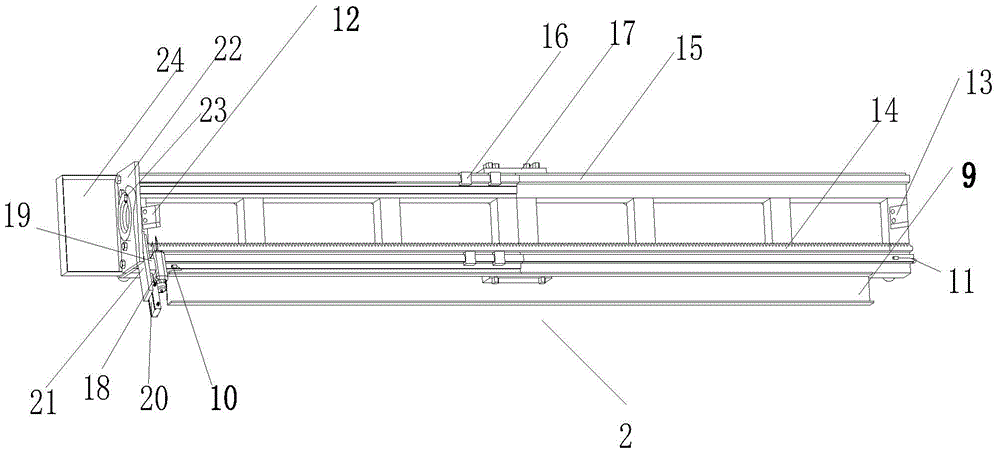

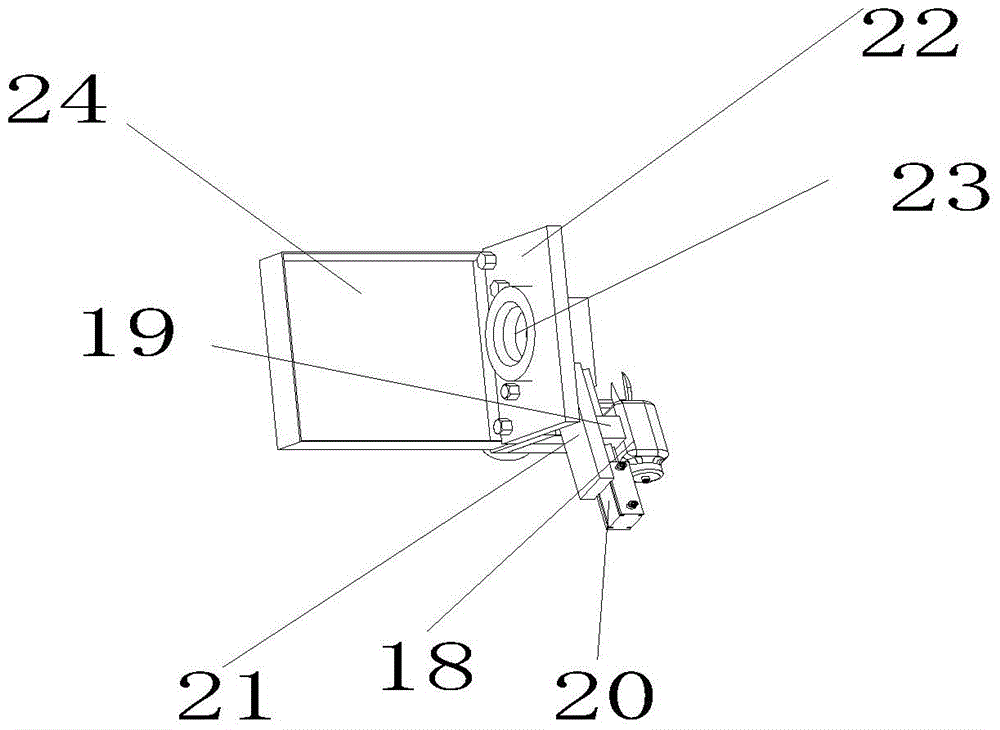

[0031] as attached Figure 1-13As shown: the present invention includes a base, on which a broaching machine is arranged, wherein: a control box is provided, and the broaching machine is provided with a drag chain of a machine tool, a clamping device, a servo motor, and a lubricating device, and the control box is connected to a lubricating device , the broaching machine is provided with a zipper fixing groove, an origin sensor and an end sensor are arranged above the zipper fixing groove, the origin sensor is located at the front end of the rack, the end sensor is located at the terminal of the rack, and above the end sensor A rack is provided, a first positioning platform and a second positioning platform are arranged above the rack, the first positioning platform is located at the front end of the rack, the second positioning platform is located at the terminal end of the rack, and a positioning platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com