Quasi-high speed broad-gauge triaxial internal combustion locomotive bogie

A technology for diesel locomotives and bogies, applied in the directions of bogies, axle box installation, railway car body components, etc., can solve the problem of inapplicability of wide-gauge countries, and achieve the effect of improving running speed and expanding product market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

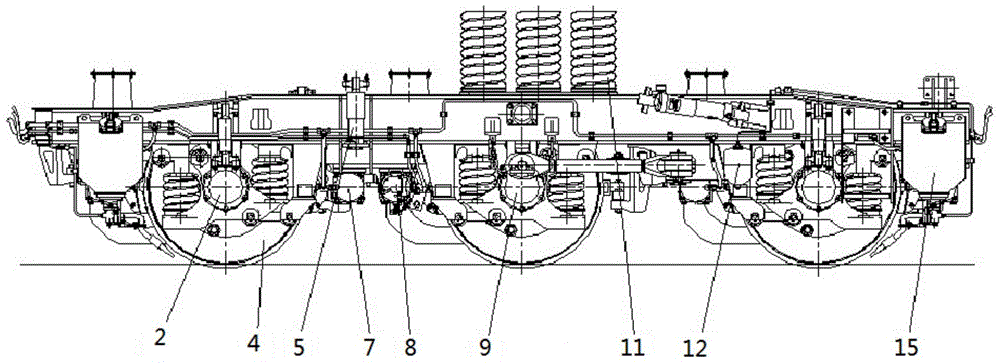

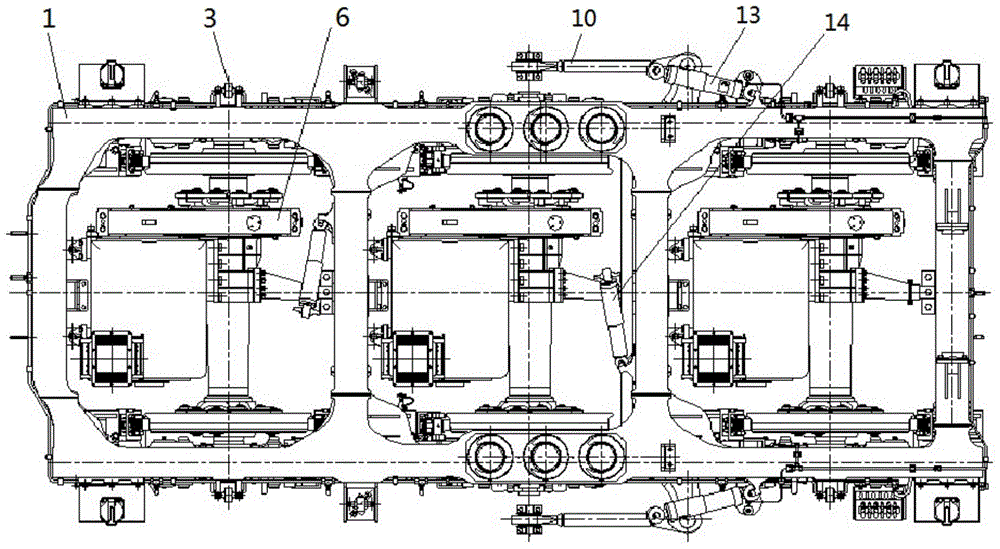

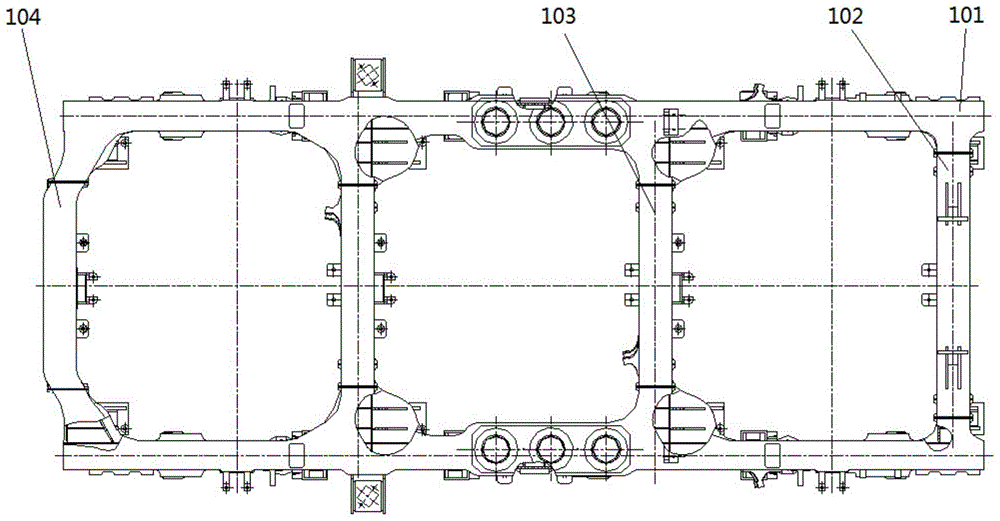

[0031] The bogie of the invention has a high-speed internal combustion locomotive three-axle bogie with high running speed, excellent curve passing performance and a running speed of 160km / h.

[0032] The composition of bogie of the present invention is: frame, wheelset, driving device, braking device, primary suspension device, support assembly, traction device, accessory assembly and wheel rim lubrication etc.

[0033] The bogie adopts the Co-Co shaft type, and the traction motor of the driving device adopts the parallel arrangement, which can effectively reduce the axle load transfer and improve the adhesion utilization rate of the locomotive. The bogie adopts the matching method of the first series of axle box springs with higher vertical stiffness, the second series of high round springs with smaller vertical stiffness, the first series of vertical shock absorbers, and the second series of vertical shock absorbers. While meeting the requirements of the frame suspension an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com