Operating platform for high bridge pier steel bars

A technology for operating platforms and high piers, which is applied to bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of low safety factor of operators and slow installation speed of steel bars, etc., so as to improve the sense of safety, increase the operating speed, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

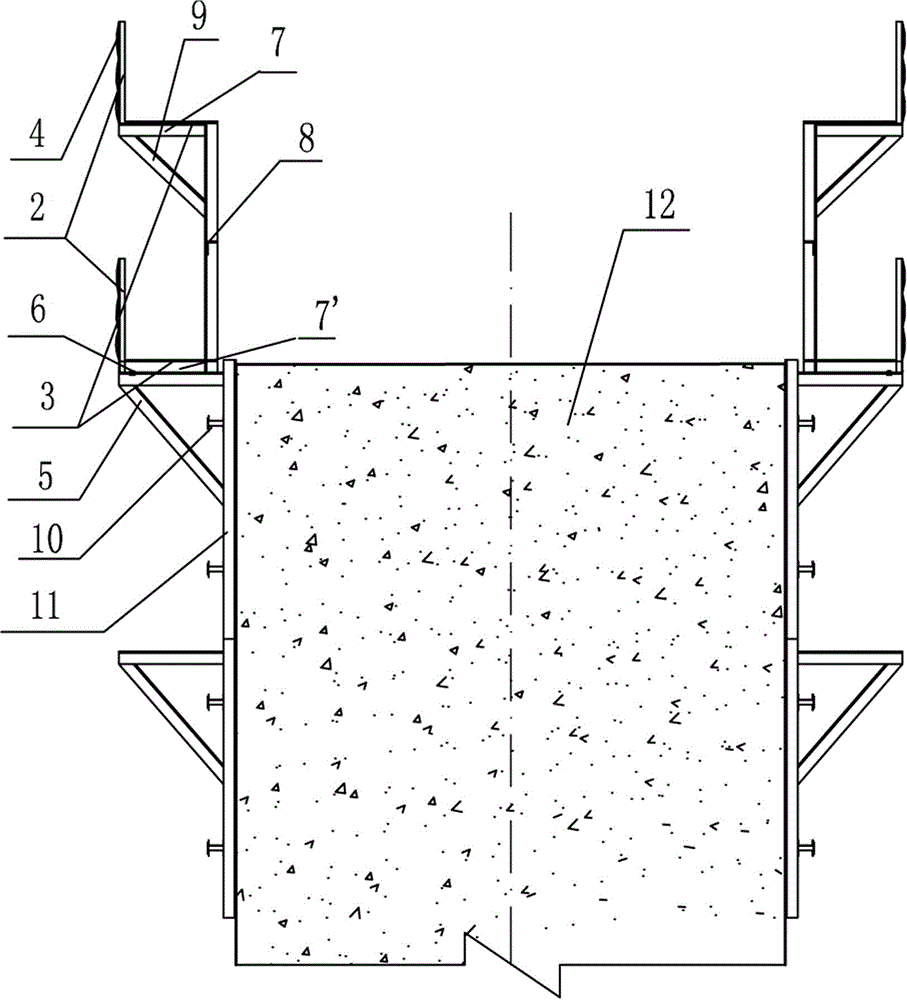

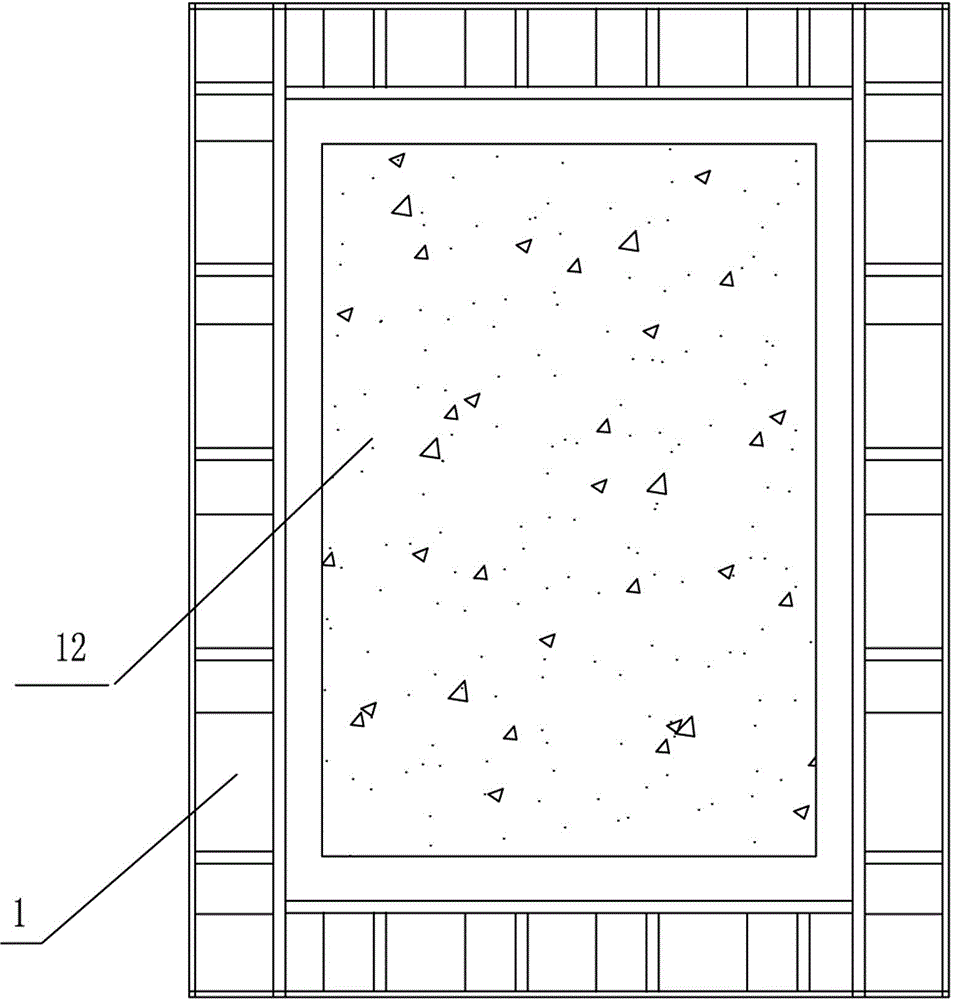

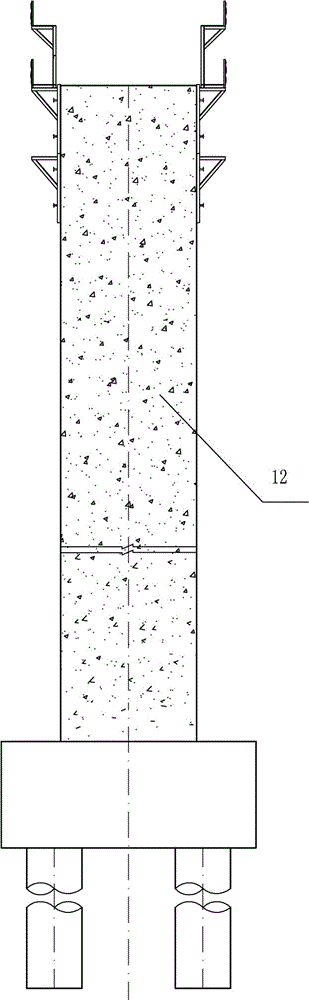

[0011] The structure of the present invention is as figure 1 As shown in -2, a steel bar working platform for high piers of a bridge, the two ends of the vertical force-bearing support 8 are respectively connected with the upper horizontal force-bearing support 7 and the lower horizontal force-bearing support 7', and the vertical force-bearing support 8 is connected with the upper horizontal force-bearing support. There is also an oblique force bearing bracket 9 between the 7, the vertical force bearing bracket, the upper and lower horizontal force bearing brackets and the oblique force bearing bracket constitute a stable and stable steel structure 1, and the upper horizontal force bearing bracket 7 is provided with Guardrail 2, a safety net 4 is installed on the guardrail 2, platform scaffolding boards 3 are paved on the upper horizontal force bearing bracket 7 and the lower horizontal force bearing bracket 7', and the lower horizontal force bearing bracket 7' passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com