Polystyrene building block structure

A technology of polystyrene and blocks, applied in the direction of building materials, etc., can solve the problems of inability to enhance beneficial effects, and achieve the effects of saving man-hours, fast assembly, and avoiding relative movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

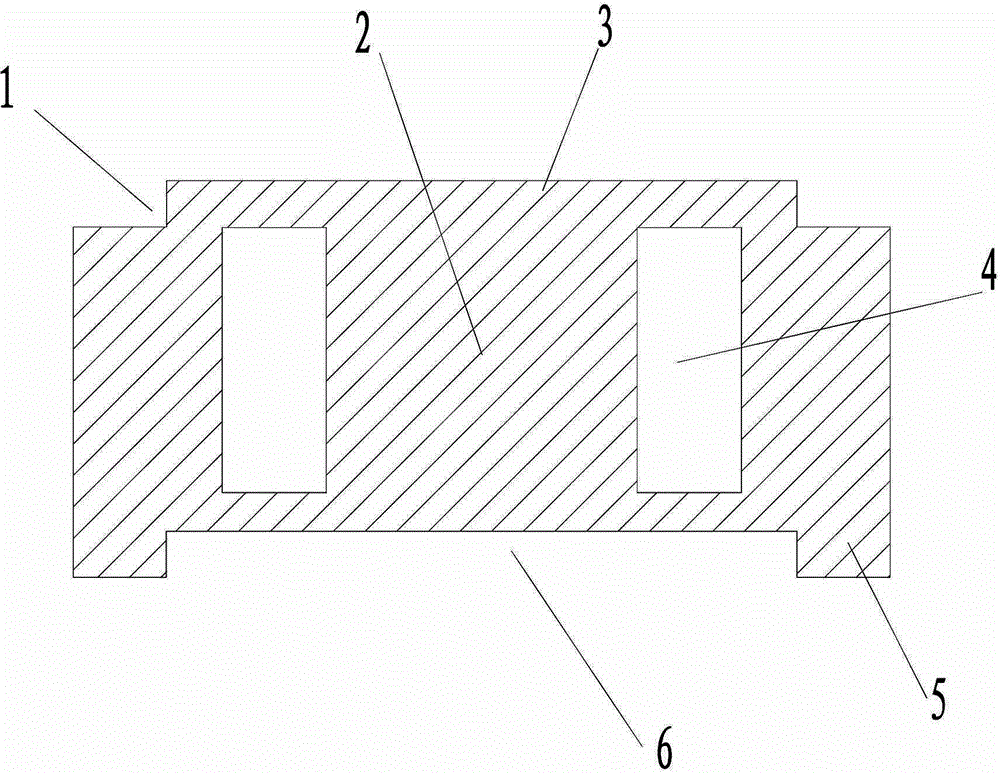

[0014] Such as figure 1 A polystyrene block structure is shown, the block is a cuboid structure as a whole, the top end surface is provided with a protrusion 3, and the bottom end surface is provided with a groove 6, and the shape and size of the inner cavity of the groove 6 are the same as those of the protrusion 3 corresponding,

[0015] Two cavities 4 are arranged symmetrically in the middle of the block.

[0016] Insulation material is arranged in the cavity 4 .

[0017] Steps 1 are formed on both sides of the protrusion 3, and protrusions 5 are formed on both sides of the groove 6. When the two blocks are stacked up and down, the protrusion 3 cooperates with the groove 6, and the steps 1 cooperates with said...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com