Concrete test block loading and curing device

A concrete test block and concrete technology, applied in the preparation of test samples, ceramic molding machines, manufacturing tools, etc., can solve the problems that cannot truly reflect the stress of the concrete curing stage, research, unfavorable concrete performance, etc., to achieve The effect of sufficient curing of the test block, convenient loading and good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the embodiment given with accompanying drawing, but embodiment does not constitute any limitation to the present invention.

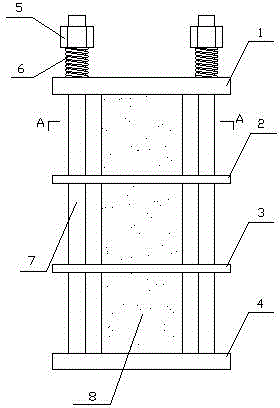

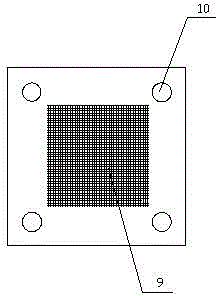

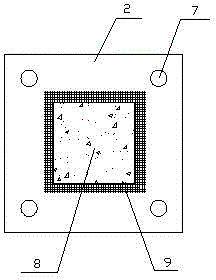

[0020] see figure 1 , figure 2 The concrete test block loading and maintenance device described in this embodiment is composed of a top plate 1, an upper middle partition 2, a lower middle partition 3, a bottom plate 4, a nut 5, a spring 6, and a screw rod 7 to form a loading frame; the nut 5 is a locknut Place three concrete test blocks 8 between the bottom plate 4 and the lower middle partition 3, between the lower middle partition 3 and the upper middle partition 2, between the upper middle partition 2 and the top plate 1, and the concrete test block 8 is A concrete cube with a side length of 100mm; the bottom plate 4, the lower middle partition 3, the upper middle partition 2, and the top plate 1 are square steel plates whose side length is longer than that of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com