Tensile-compression integrated fixture for mechanical creep testing machine

A creep test and mechanical technology, applied in the field of material mechanics research, can solve problems such as the limitation of the creep loading range and direction of action, and achieve the effects of high machining accuracy, convenient use and guaranteed accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

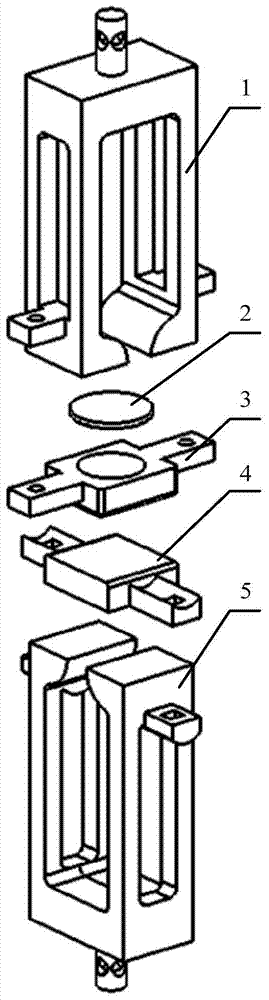

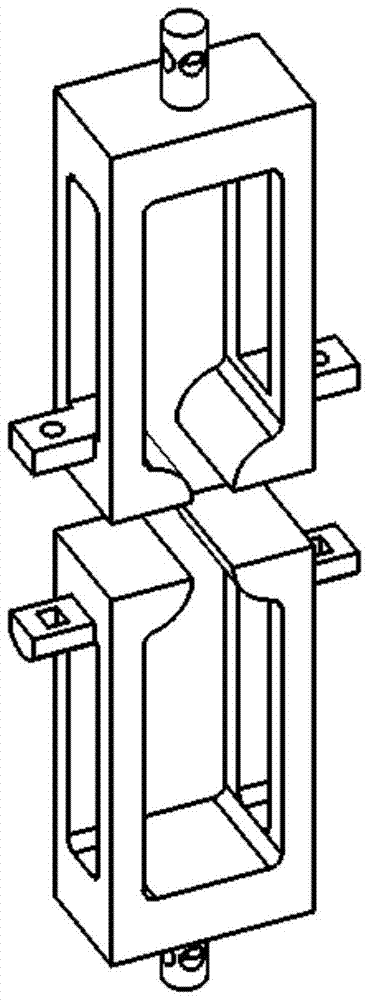

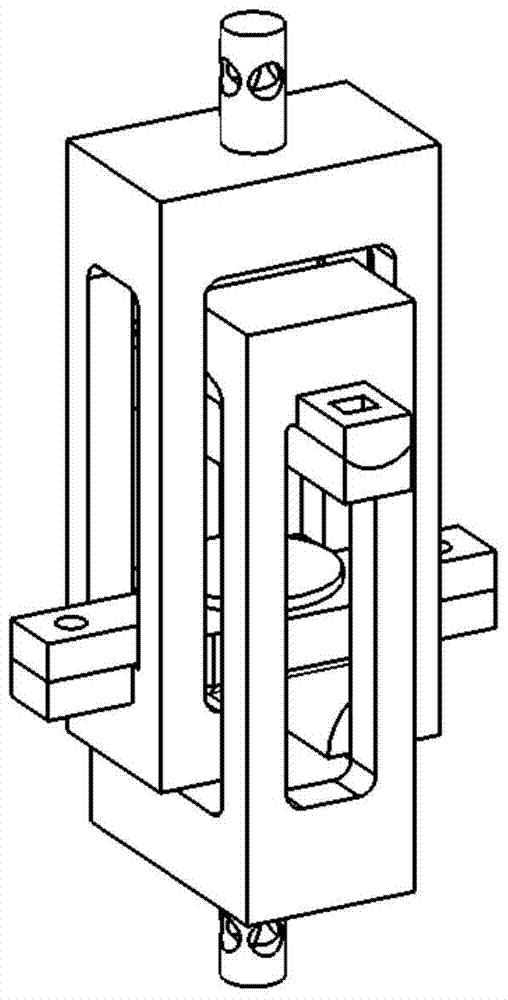

[0014] combine figure 1 :

[0015] The present invention is a tension-compression integrated fixture for a mechanical creep testing machine, comprising an upper tension chuck 1, an adjustment ball head 2, a lower compression chuck 3, an upper compression chuck 4 and a lower tension chuck 5; The tensile chuck 1 and the lower tensile chuck 5 are dumbbell-shaped specimen tensile chucks, the two sides of the tensile chuck are slotted, and the slot of the upper tensile chuck 1 is set outward near the opening of the tensile chuck There is a boss carrying the lower compression collet 3, and the slot of the lower stretching collet 5 is provided outwardly near the opening of the stretching collet with a boss carrying the upper compression collet 4, the lower compression collet 3 and the upper compression collet 4 The shape of both ends matches the boss, the middle part is the working surface, and the working surface of the lower compression chuck 3 has an inwardly recessed spherical s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap