Oil production simulation system and simulation method

A simulation system and simulation method technology, which is applied to simulators, space navigation condition simulation devices, teaching models, etc., can solve the problems of large floor area, training on site, and high airtightness requirements, and achieve equipment footprint The effect of small area, improved training effect, and high simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

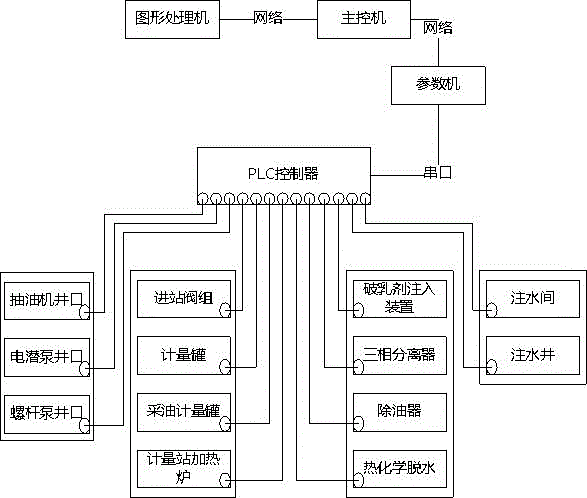

[0040] Such as figure 1 As shown, the oil production simulation system includes an oil production simulation device, a PLC controller and a control unit. The control unit includes a main control machine, a parameter machine and a graphics processor. The oil production simulation device is connected with the PLC controller, and the PLC controller communicates with the parameter The parameter computer and the graphics processor are respectively connected to the main control computer through the communication network;

[0041] The described oil production simulation device is provided with valves, display meters, switches, etc., and the PLC controller is provided with a collector for circularly collecting the valve opening and switch state on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com