Lithium ion battery group matching method

A lithium-ion battery and battery technology, which is applied in the field of lithium-ion batteries, can solve the problems of inability to guarantee the performance of battery modules, low accuracy, inconsistency, etc., so as to improve and improve the quality of the assembly, good performance, safety and efficiency. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

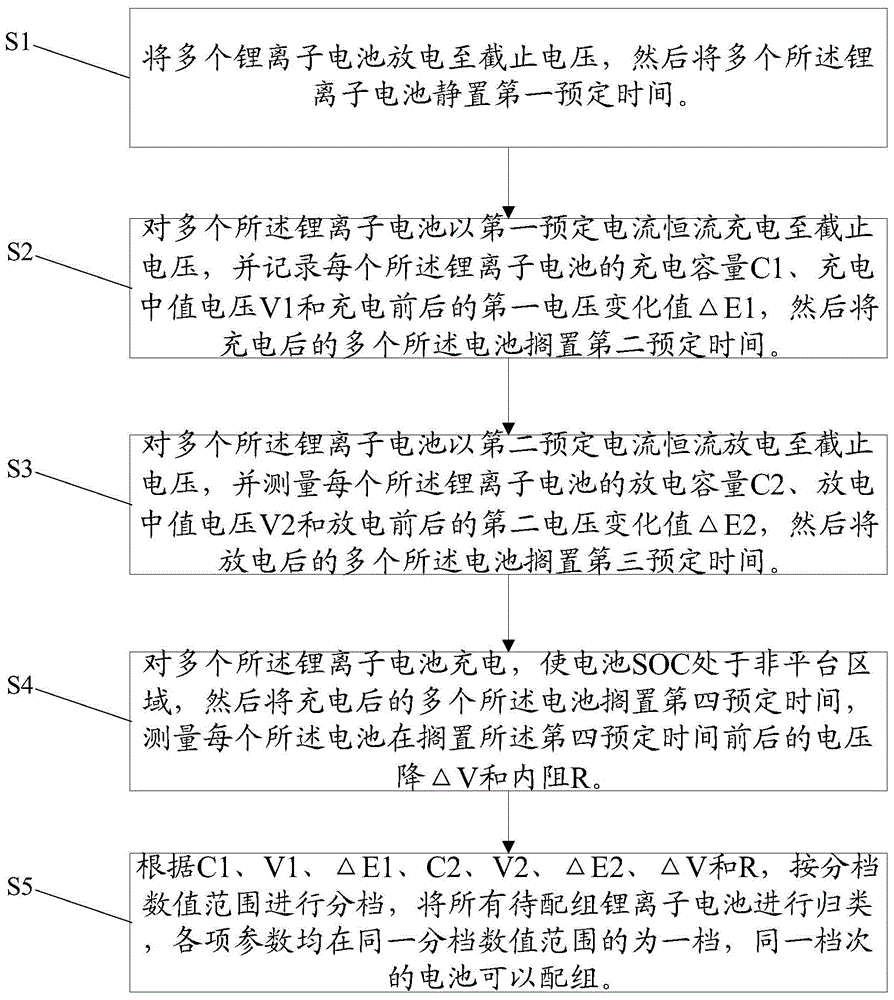

[0024] As shown in Figure 1, the lithium-ion battery assembly method of the embodiment of the present invention includes the following steps:

[0025] Step S1, discharging a plurality of lithium-ion batteries to a cut-off voltage, and then allowing the plurality of lithium-ion batteries to stand still for a first predetermined time. Since the lithium-ion battery stores a certain amount of electricity when it is placed, the electricity stored in the lithium-ion battery can be discharged through this step. The first predetermined time is preferably 10-20 minutes, further, the first predetermined time is preferably 10 minutes.

[0026] Step S2, charging a plurality of said lithium-ion batteries to a cut-off voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com