High-voltage resistant electrical connector plug, socket, manufacturing method and electrical connector

A technology for connector plugs and connector sockets, which is applied in the direction of connection, two-part connection device, and parts of the connection device, etc., can solve the problems of short creepage distance, small size of electrical connectors, and reduced withstand voltage performance. The effect of high reliability, small size and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

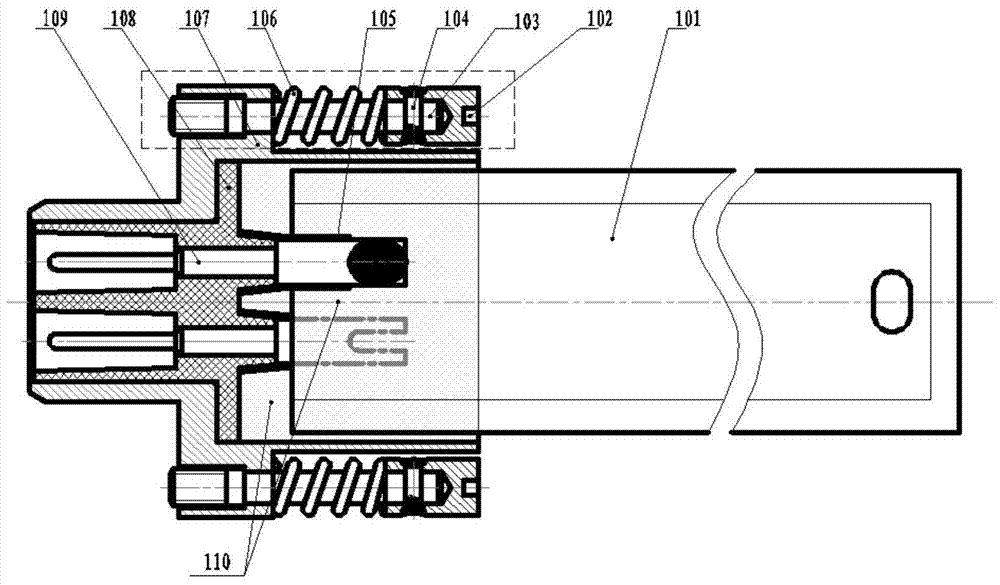

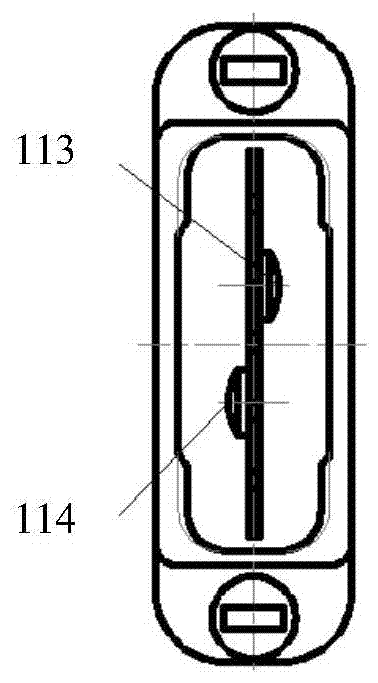

[0029] Figure 1a , Figure 1b A schematic structural diagram of a small-volume, high-voltage electrical connector plug 111 designed for the patent of the present invention. The electrical connector plug 111 includes a pin 109, a plug heat-shrinkable sleeve 105, a plug mounting plate 108, a plug housing 107, a spring 106, a rivet 104, a screw 103, a screw cap 102, a plug sealant 110, and a shock plate detonator. The cable 101 is connected to the electrical connector plug 111 by welding with the pin 109 . The material of plug mounting plate 108 is polybutylene terephthalate (PBT) and other engineering plastics, which are used for insulating and fixing the installation position of pin 109; The pads of the cable 101 are welded. The cable 101 can be flat or other shapes. The minimum distance between two pins ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com