Seal ring

A technology of sealing ring and annular groove, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problem of response characteristic decline, and achieve the effect of suppressing leakage and suppressing sliding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

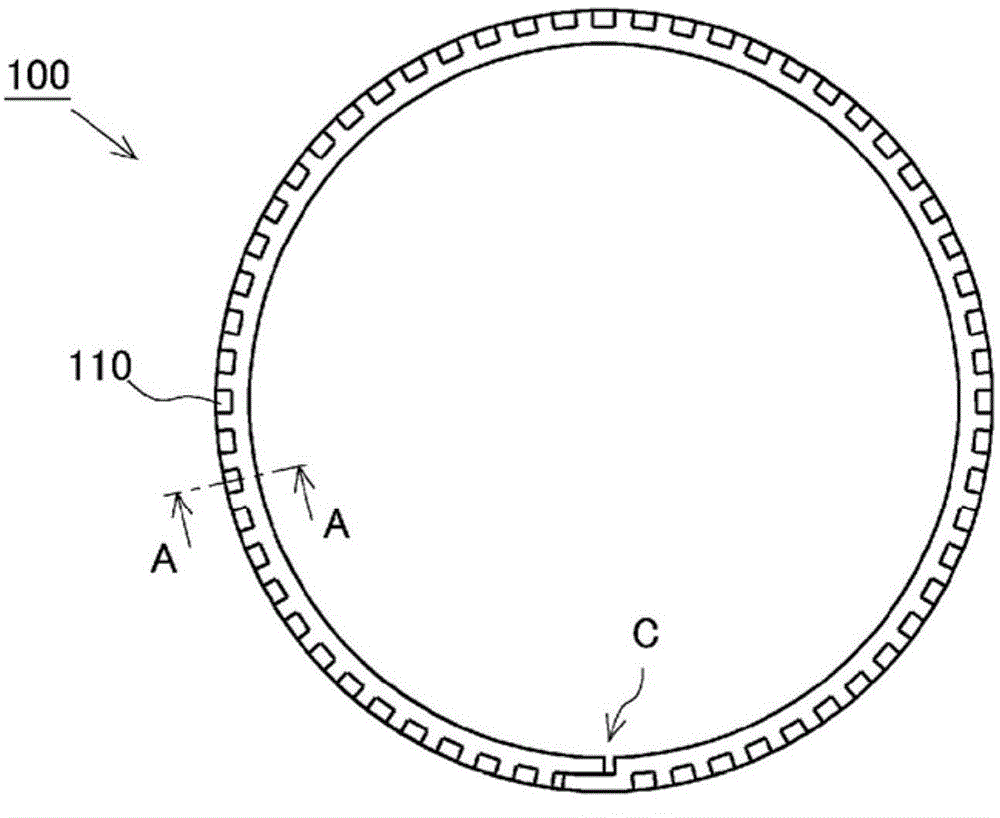

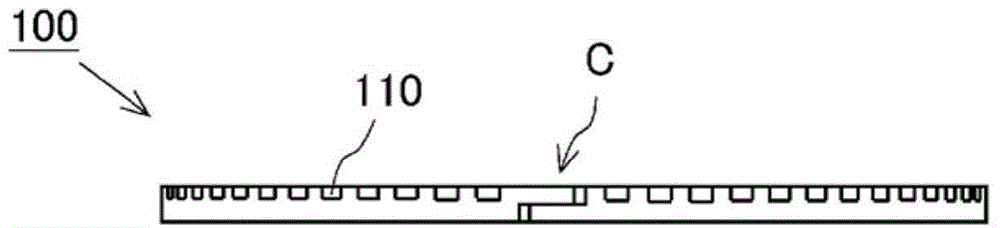

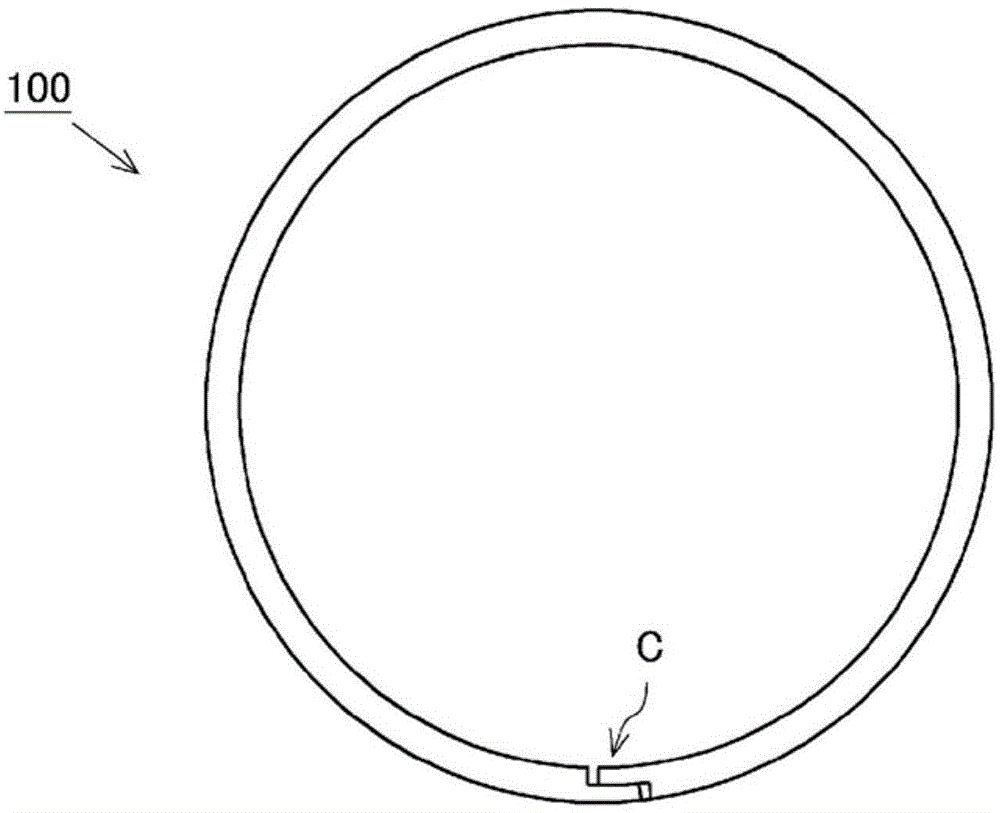

[0074] Below, refer to Figure 1 to Figure 6 The seal ring of Example 1 of the present invention will be described. The sealing ring of this embodiment is installed in an annular groove provided on the outer periphery of the shaft, and is used to seal the annular gap between the shaft and the casing, and separate the high-pressure area and the low-pressure area where the fluid to be sealed is located. In this embodiment, the shaft is rotated relative to the housing. However, the seal ring of the present invention is also applicable to a structure in which the housing rotates with respect to a shaft, and a structure in which both the shaft and the housing rotate relatively.

[0075] (Structure of sealing ring)

[0076] Figure 1 to Figure 4 It is a figure which shows the structure of the seal ring 100 of this Example. figure 1 , image 3 is a side view of the seal ring 100 . figure 1 Indicates the side facing the low-pressure area side when the seal ring 100 is installe...

Embodiment 2

[0094] Below, refer to Figure 7 , Figure 8 The seal ring of Example 2 of the present invention will be described. The seal ring of this embodiment differs from the seal ring of Embodiment 1 in the groove structure. The description of the same structure and function as in the first embodiment is omitted here.

[0095] (Structure of sealing ring)

[0096] Figure 7 It is a partial side view of the seal ring 100a of this embodiment. Figure 7 The side surface of the seal ring 100a on the low-pressure region (L) side is shown.

[0097] In the seal ring 100a of this embodiment, a plurality of side grooves 110a are provided on the side surface on the low-pressure region (L) side. As in the first embodiment, the side groove 110 a extends from the outer peripheral surface to the inner peripheral surface to a position not reaching the inner peripheral surface. In Embodiment 1, the side groove 110 provided on the side surface of the seal ring 100 extends in the radial direction...

Embodiment 3

[0104] Below, refer to Figure 9 The seal ring according to Example 3 of the present invention will be described. The seal ring of this embodiment differs from the seal ring of Embodiment 1 in the groove structure. The description of the same structure and function as in the first embodiment is omitted here.

[0105] (Structure of sealing ring)

[0106] Figure 9 It is a partial side view of the seal ring 100b of this embodiment. Figure 9 The side surface of the seal ring 100b on the low-pressure region (L) side is shown.

[0107] In this embodiment, the shaft 200 rotates not only in the forward direction but also in the reverse direction relative to the casing 300 . In addition, in the seal ring 100b of this embodiment, a plurality of side grooves 110a, 110b are respectively provided on the side surface on the low-pressure region (L) side. As in the first embodiment, the side grooves 110a and 110b extend from the outer peripheral surface to the inner peripheral surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com