Method for making green plant protection facilities based on light steel structure

A technology for protective facilities and green plants, applied in the direction of plant protection cover, etc., can solve the problems of polluting the environment, hindering traffic, and manpower consumption of forest resources, etc., to achieve the effect of improving life expectancy, reducing costs, and reducing resource consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] (1) Surveying and mapping site: determine the length, width and height of the wind screen or canopy.

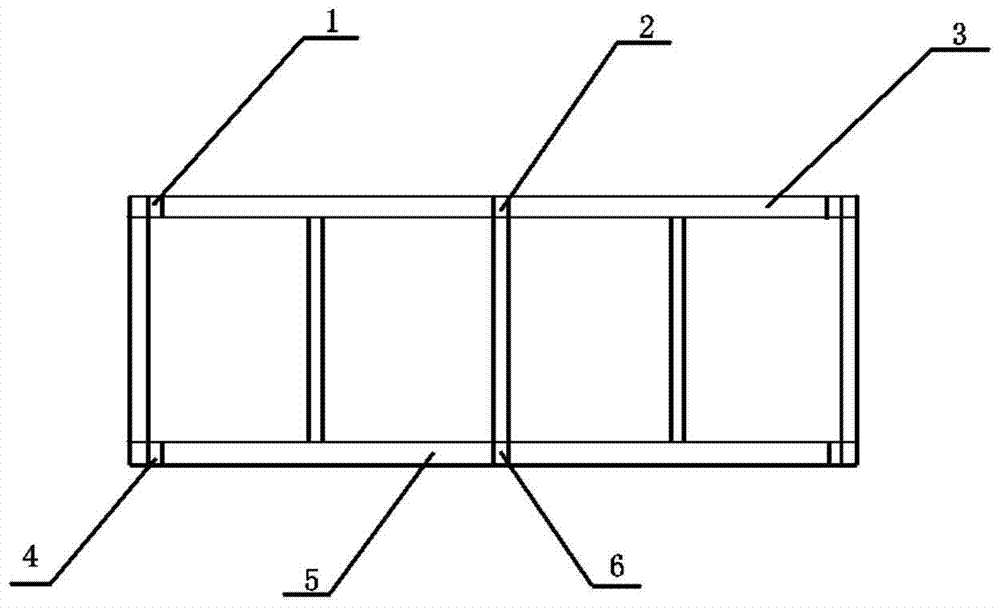

[0024] (2) Component design: simplify the design of the wind screen as "two nails on one side", that is, the facade, sky nails and ground nails; simplify the design of the canopy as "one cover and two nails on both sides", that is, two facades and one upper cover , sky nails and ground nails.

[0025] (3) Workshop production:

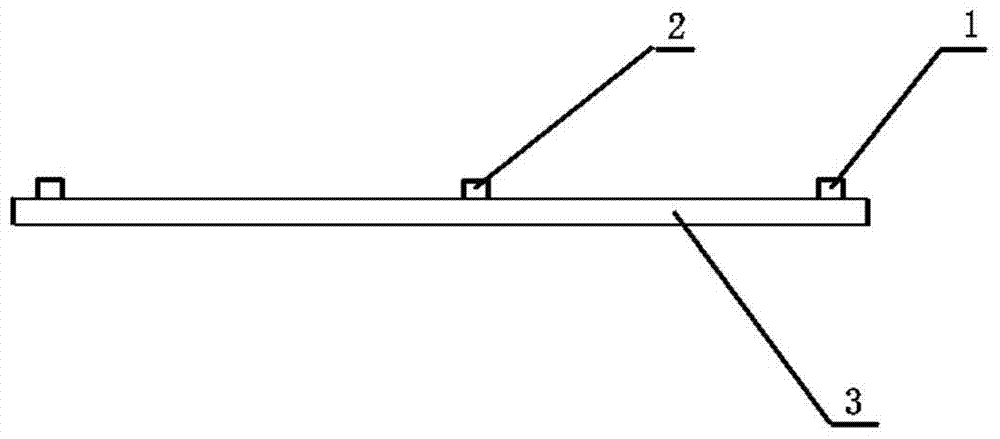

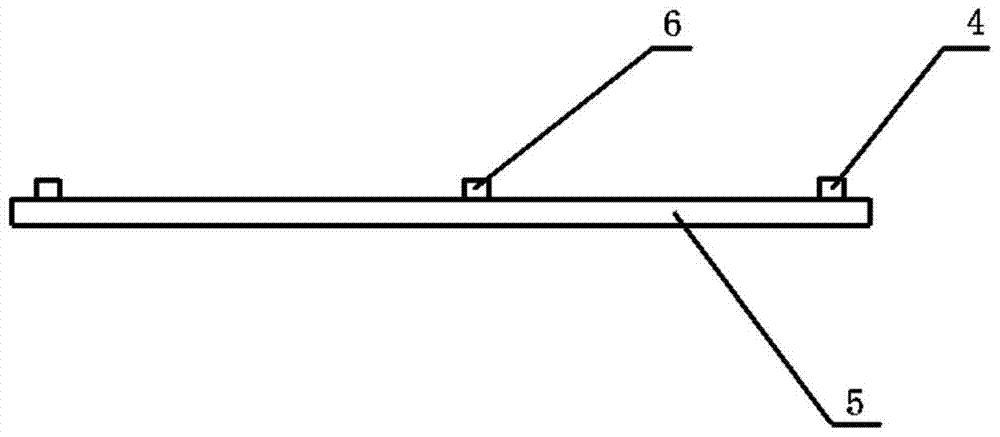

[0026] Facade: Weld a rectangular frame with galvanized steel pipes, weld the sky nail hole 1 at both ends of the upper edge 3 of the frame and weld the middle sky nail hole 2 at the middle position, weld the ground nail hole 4 and the middle at both ends of the lower edge 5 of the frame Weld the nail hole 6 in the middle.

[0027] Upper cover: galvanized steel pipe welded into a rectangular frame.

[0028] Fragmentation: Bond plastic woven fabric to the welded frame to make façade fragmentation and upper cover fragmentation.

[0029] Ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com