Stone jaw crusher

A crusher and jaw type technology, applied in the field of mining equipment, can solve problems such as inconvenient adjustment, troublesome installation, complex structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

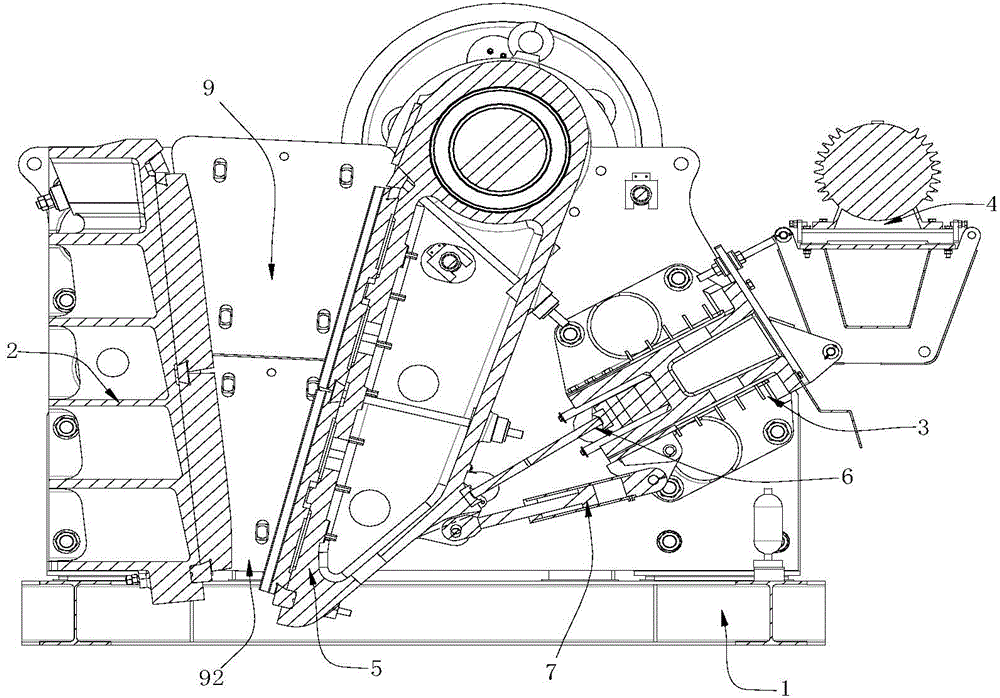

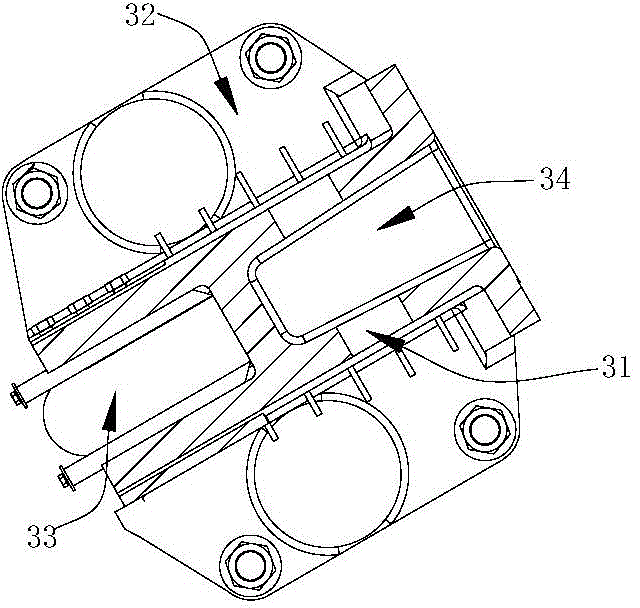

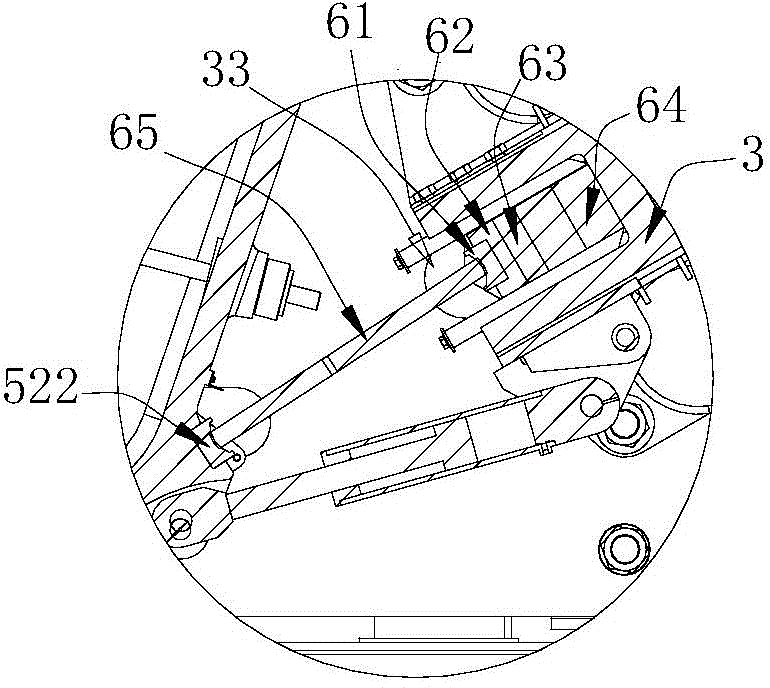

[0017] Such as Figure 1~Figure 3 A stone crusher with a jaw structure shown includes a frame, and a drive unit 4, a movable jaw group 5, a discharge opening adjustment mechanism 6 and a movable jaw tensioning buffer mechanism 7 arranged on the frame; The frame includes a frame body 1, a fixed jaw frame 2 arranged at the front end of the frame body 1, and a toggle plate frame 3 arranged at the rear end of the frame body 1, and the movable jaw group 5 is installed between the fixed jaw frame 2 and the elbow. On the frame main body 1 between the plate frames 3, between the movable jaw group 5 and the fixed jaw frame 2 is the crushing chamber 9; The jaw tightening buffer mechanism 7 is installed on the toggle frame 3 , the front end of the outlet adjusting mechanism 6 is against the movable jaw group 5 , and the front end of the mov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap