Bearing detecting and sorting device based on machine vision

A technology of machine vision and bearing inspection, applied in sorting and other directions, can solve the problems that it is difficult to ensure complete visual coverage of the bearing surface and detection efficiency at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

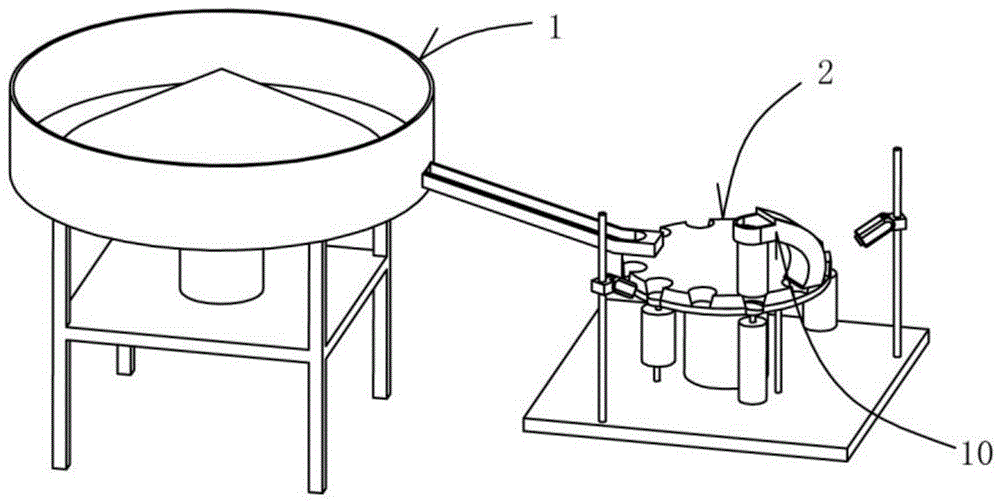

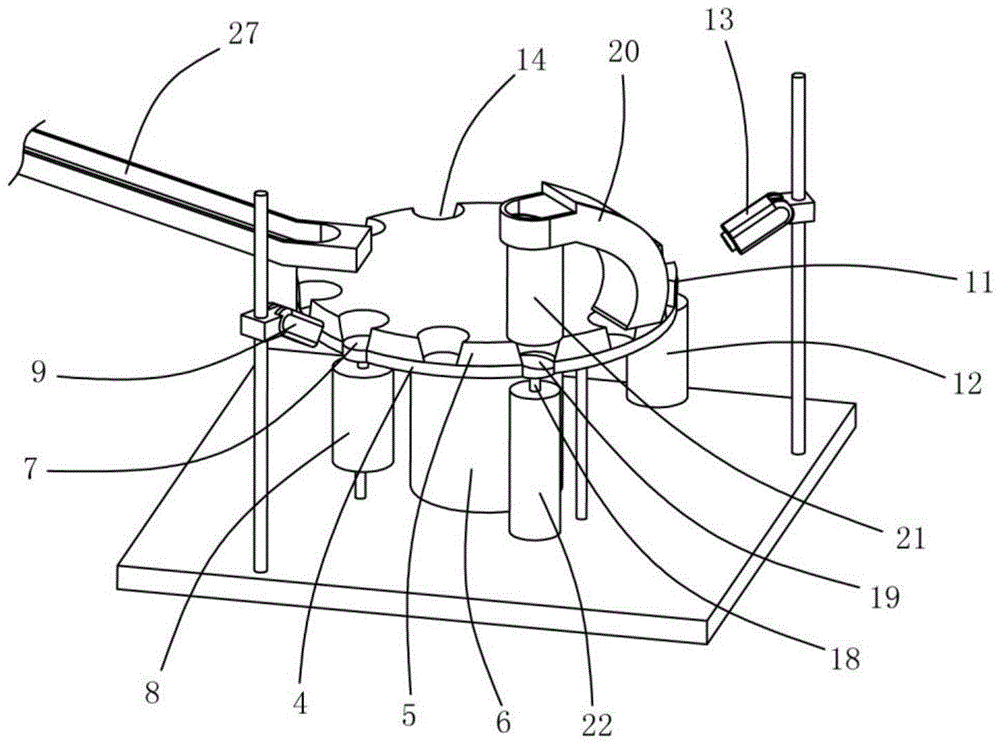

[0020] see Figure 1-Figure 7 , a bearing detection and sorting device based on machine vision, including a feeding mechanism 1, a detection mechanism 2 and a sorting mechanism 3, the workpieces to be detected pass through the feeding mechanism 1, the detection mechanism 2 and the sorting mechanism 3 in sequence, and the feeding Mechanism 1 transports workpieces to be detected to detection mechanism 2, and detection mechanism 2 uses machine vision to detect the workpieces to be detected, and sorting mechanism 3 sorts corresponding workpieces to be detected according to the detection signal of detection mechanism 2.

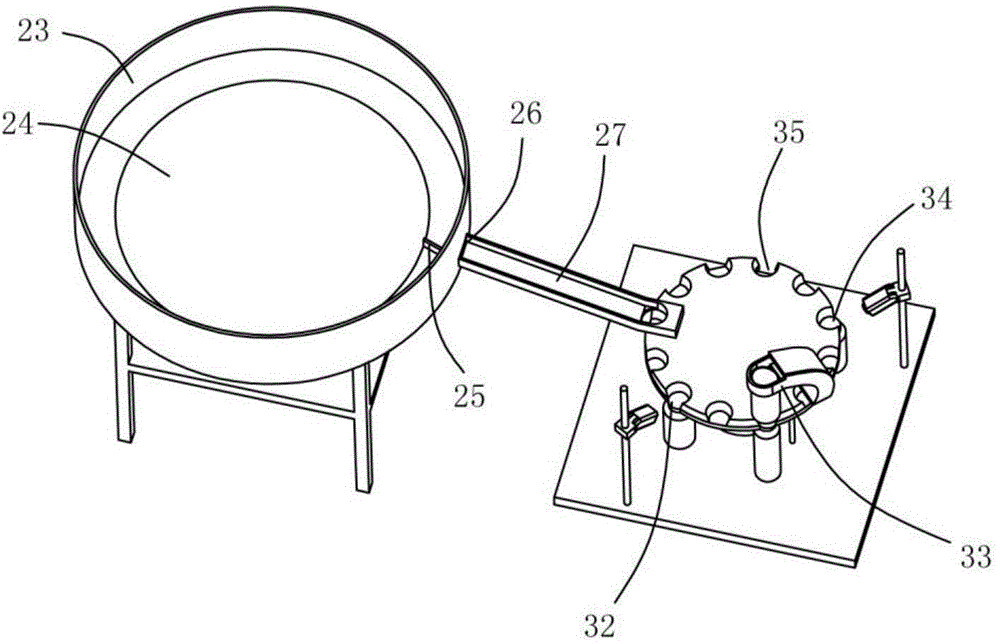

[0021] The feeding mechanism 1 comprises a bucket 23 and a conical disk 24 located in the bucket 23, the chassis of the bucket 23 is driven by a motor to rotate, the inner wall of the bucket 23 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com