Method and device for splicing multi-face units into integral material

A technology of integral material and surface unit, applied in the direction of material gluing, connecting components, welding equipment, etc., can solve the problems of difficult operation, high manufacturing cost, and difficult realization, etc., and achieve the effect of high processing efficiency and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

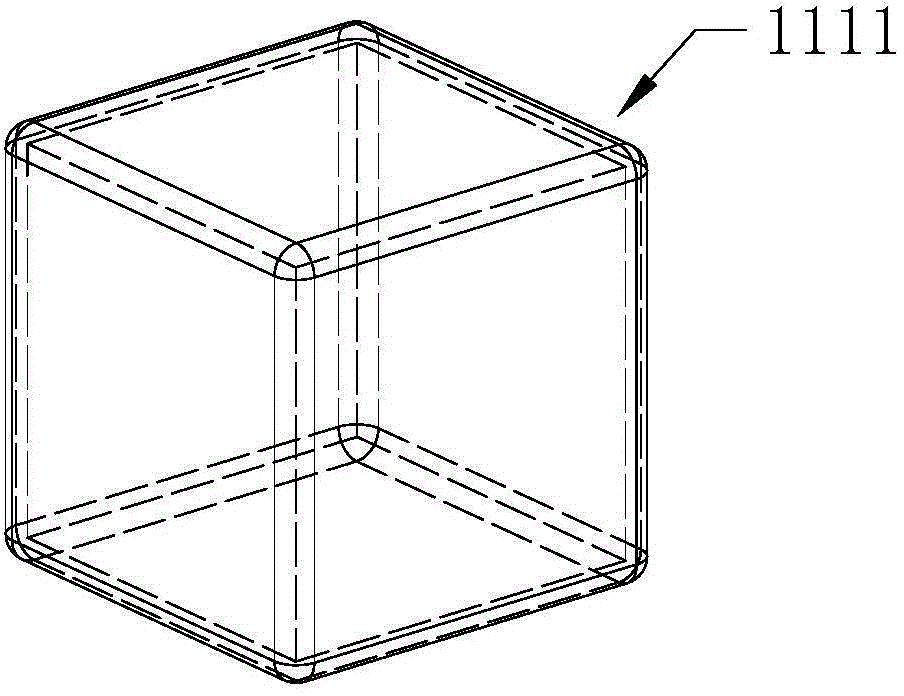

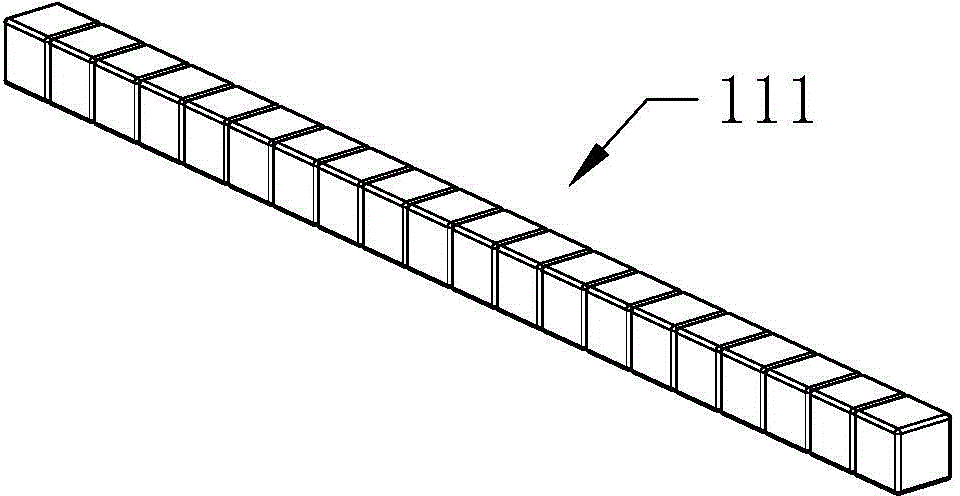

[0057] The activities of the pushing plate 23 and the pressing member 24 can be operated manually or automatically. The present invention provides an implementation mode that is operated in an automated manner: the above-mentioned device 2 for splicing the multi-face unit body 1111 into an integral material also includes a first pressurizing device 27 for providing a pressure source for the pressing plate 23 and a device for The second pressurizing device 28 that provides a pressure source for the pressing member 24, the first pressurizing device 27 and the second pressurizing device 28 are both arranged on the base 21, and the pushing plate 23 It is connected with the first pressurizing device 27 , and the pressing member 24 is connected with the second pressurizing device 28 .

[0058] The first pressurizing device 27 and the second pressurizing device 28 may be cylinders or motors, or other internal or external devices capable of providing pressure sources. The first press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com