Tube curvature compensation method and laser cutting device

A compensation method and laser cutting technology, which is applied in laser welding equipment, tubular objects, applications, etc., can solve problems such as increased production costs, damaged cutting heads, and discrepancies in positions, and achieves the effect of improving the pass rate and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

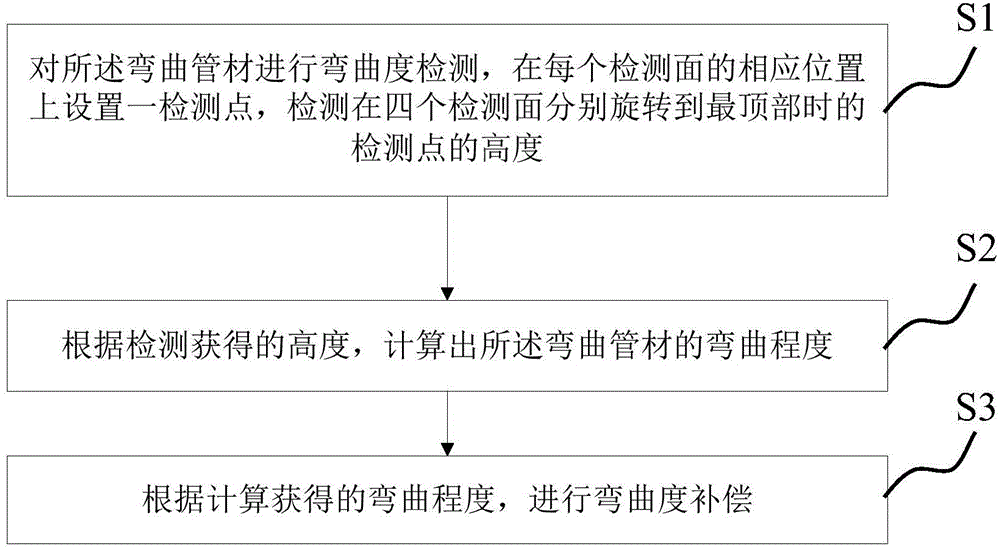

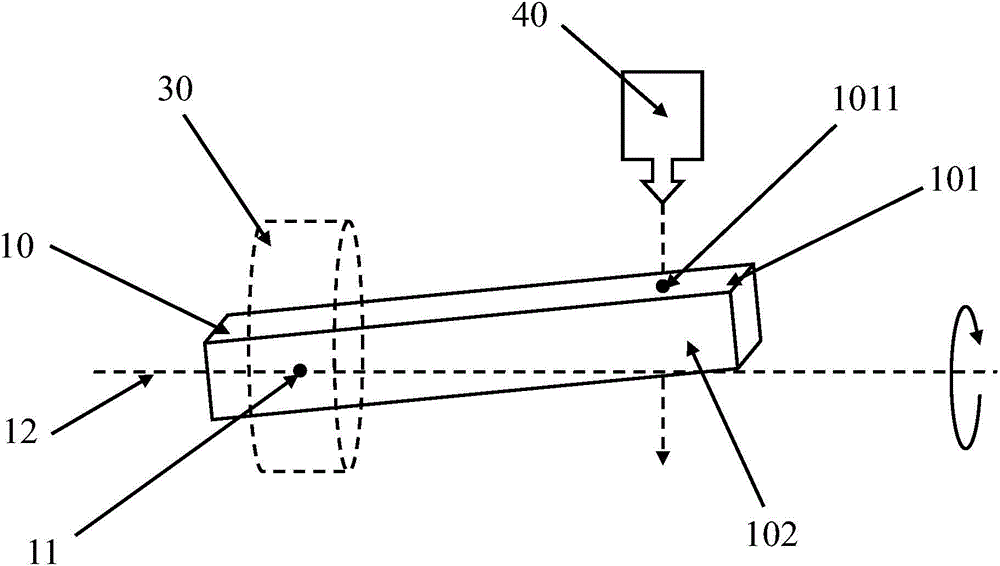

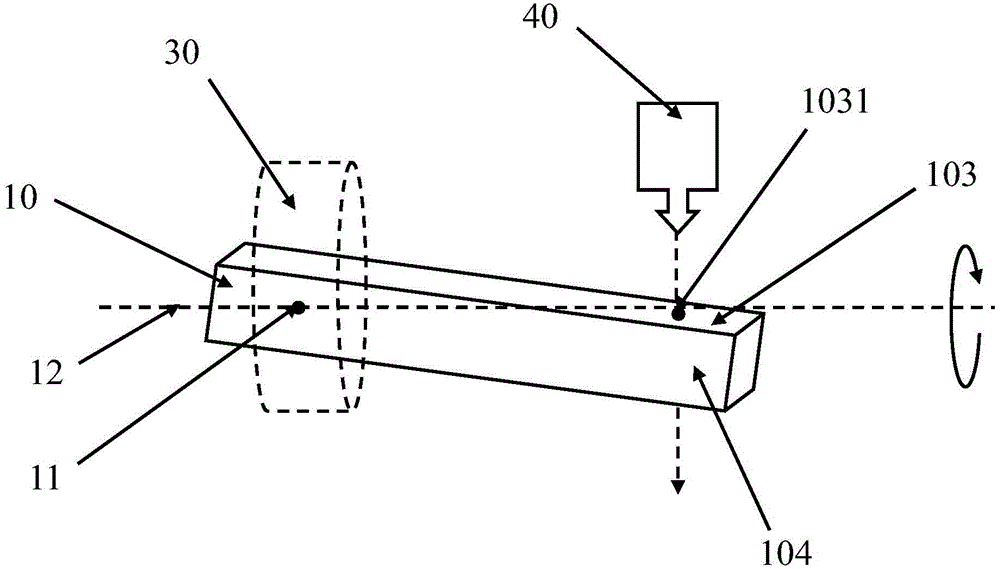

[0033] like Figure 1~5 As shown, a preferred embodiment of the pipe curvature compensation method is provided, wherein figure 1 is the schematic block diagram of the curvature compensation method, figure 2 is the detection indication of the compensation method Figure 1 , image 3 is the detection indication of the compensation method Figure II , Figure 4 is the schematic diagram of the curved pipe structure, Figure 5 is the schematic diagram of the cutting profile of the curved pipe.

[0034] A method for compensating the bending degree of a pipe. Before compensation, the curved pipe 10 is clamped by the clamping member 30, and the curved pipe 10 is rotated around the rotation axis 12. The rotation axis 12 is a horizontal axis passing through the center 11 of the clamping position, and the compensation After the bending operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com